Method for producing homogenous carbonized wood by using pinus massoniana wood as raw material

A technology of homogeneous carbonized wood and production method, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of less application, insufficient economic value, destruction of precious tree species or wild wood, etc., to achieve expanded application field, the effect of improving application value and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

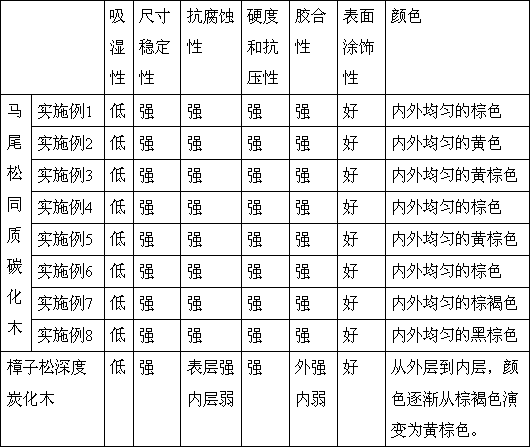

Examples

Embodiment 1

[0028] Cut and saw 10m3 masson pine wood into a wood with a length of 100cm and a thickness of 2cm; then immerse in a 20% lime solution and boil continuously for 5 hours, then put it into clean water and rinse it, and then immerse in a concentration of 1‰ hydrogen peroxide solution Boil continuously for 5 hours, then rinse in clean water; then adjust the temperature in the conventional steam drying kiln to 72°C, and spray water vapor into the conventional steam drying kiln to make it saturated, and then degrease the masson pine Put the wood in a conventional steam drying kiln to fully absorb water. After 25 hours, the masson pine wood absorbs water to reach saturation, then stop spraying water vapor, adjust the temperature in the conventional steam drying kiln to 65°C, and keep the kiln for 12 hours, then open the vent hole to Exhaust outside, and gradually increase the temperature in the conventional steam drying kiln to 82°C, and dehydrate for 3 hours; repeat this twice, then...

Embodiment 2

[0031] Cut and saw 10m3 early wood of masson pine wood into a wood with a length of 200cm and a thickness of 5cm; then immerse in a 20% lime solution and boil continuously for 5 hours, then put it into clean water and rinse it, and then immerse in a concentration of 1‰ Boil continuously in hydrogen peroxide solution for 5 hours, then rinse in clean water; then adjust the temperature in the conventional steam drying kiln to 72°C, and spray water vapor into the conventional steam drying kiln to make it saturated, and then degrease the Put the masson pine wood into the conventional steam drying kiln to fully absorb water. After 25 hours, the masson pine wood absorbs water to reach saturation, then stop spraying water vapor, adjust the temperature in the conventional steam drying kiln to 65°C, and keep the kiln for 12 hours, then turn on the exhaust The hole is exhausted outward, and the temperature in the conventional steam drying kiln is gradually raised to 82°C, and the dehydrat...

Embodiment 3

[0034] Cut and saw 10m3 early wood of masson pine wood into a wood with a length of 200cm and a thickness of 5cm; then immerse in a 20% lime solution and boil continuously for 5 hours, then put it into clean water and rinse it, and then immerse in a concentration of 1‰ Boil continuously in hydrogen peroxide solution for 5 hours, then rinse in clean water; then adjust the temperature in the conventional steam drying kiln to 73°C, and spray water vapor into the conventional steam drying kiln to make it saturated, and then degrease the Put the masson pine wood in a conventional steam drying kiln to fully absorb water. After 26 hours, the masson pine wood absorbs water to a saturated state, then stop spraying water vapor, adjust the temperature in the conventional steam drying kiln at 66°C, and keep the kiln for 12.5 hours, then turn on the exhaust The hole is exhausted outward, and the temperature in the conventional steam drying kiln is gradually raised to 83°C, and the dehydrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com