The preparation method of the solvent-free anion/nonionic waterborne polyurethane acrylate graft copolymer with ipn structure

A water-based polyurethane and acrylate technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of unfavorable color palette personnel, differences in dry humidity of paint films, poor physical and mechanical properties of paint films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

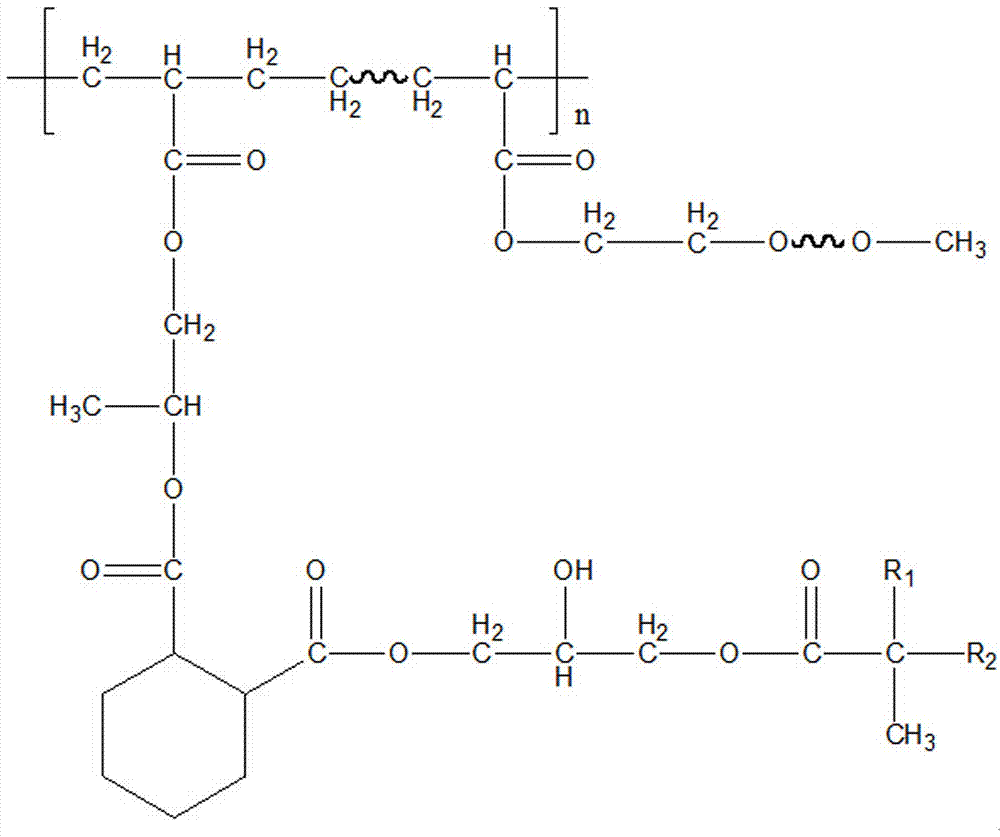

[0118] 1. Synthesis of solvent-free anion / nonionic PUA containing IPN structure

[0119] The synthetic formula of the solvent-free anion / nonionic PUA with IPN structure is shown in Table 3, and its synthetic process is as follows: 1. in the reactor equipped with agitator, condenser, thermometer, electric heating mantle and vacuum pump, first Add glycidyl tert-carbonate, heat up to 130-140°C, then add o-cyclohexanedioic acid-1-[1-methyl-2-[(1-oxo-2-propenyl)oxy]ethyl ] ester, part of MMA, triethylene glycol monomethyl ether acrylate, ethoxylated trimethylolpropane triacrylate and part of the mixture of di-tert-amyl peroxide and dodecyl mercaptan are added dropwise into the reactor, After 3-4 hours of dripping, add the remaining MMA and initiator, drop it within 0.5 hours, and finally keep it at 150°C for 2 hours to prepare PA prepolymer; Mix ester diol, polyethylene glycol monomethyl ether dimethylol propionate, trimethylolpropane and IPDI evenly, add to the reaction kettle, r...

Embodiment 2

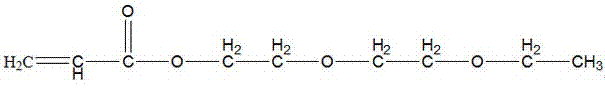

[0136] Table 6 shows that in Example 2, under the condition that the amount of other monomers is kept constant, ethoxy ethoxy ethyl acrylate, triethylene glycol monomethyl ether acrylate, methoxy polyethylene glycol 400 acrylic acid are respectively used ester and methoxypolyethylene glycol 550 acrylate to synthesize a solvent-free anionic / nonionic PUA with IPN structure. The formula numbers are 5, 6, 7 and 8, and there are 4 formulas in total. The synthesis process of each recipe is the same.

[0137] According to the technical process of the anion / nonionic PUA of solvent-free synthesis with IPN structure according to embodiment 1, numbering is 4 kinds of PUA shown in table 6 as 5~8, prepares by the formula of embodiment 1 coating and the process of mixing paint The one-component water-based metallic glitter paint for automobiles containing the solvent-free anion / nonionic PUA with IPN structure prepares the paint film according to the construction method of the metallic glitt...

Embodiment 3

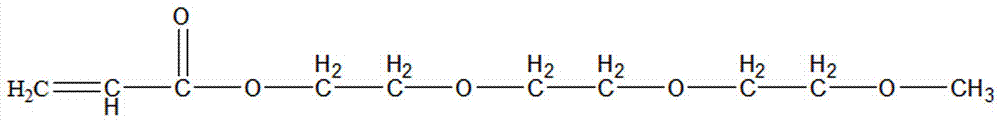

[0146] Table 8 changes the amount of triethylene glycol monomethyl ether acrylate to synthesize the basic formula of the solvent-free anion / nonionic PUA with IPN structure

[0147]

[0148]

[0149] Table 8 is that in Example 3, under the condition that the amount of other monomers is kept constant, the amount of triethylene glycol monomethyl ether acrylate is gradually increased to 11g, 18g, 25g and 32g to synthesize solvent-free compounds with IPN structure. The feeding formulas of anionic / nonionic PUA are numbered 9, 10, 11 and 12 in sequence, and there are 4 formulas in total. The synthesis process of each recipe is the same.

[0150] According to the technical process of the anion / nonionic PUA of solvent-free synthesis with IPN structure according to embodiment 3, numbering is 4 kinds of PUA shown in table 8 as 9~12, prepares by the formula of embodiment 1 coating and the process of mixing paint The one-component water-based metallic glitter paint for automobiles c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com