Tough curtain coating soft-light finish paint on impregnated laminate flooring

A technology for strengthening floors and soft glossy surfaces, applied in coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of high cost, lack of layered wood grain on the floor, and high price, and achieve smooth hand feel, Excellent surface properties, improved boiling resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

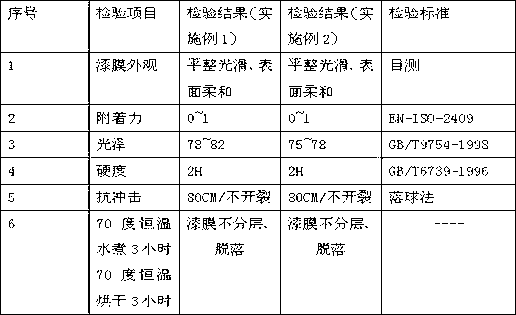

Examples

Embodiment 1

[0012] A kind of tenacity drenching coating soft light topcoat on the impregnated reinforced floor, this topcoat is matte paint, and the component of this soft light topcoat and its weight ratio are: 100% UV curable resin 50%; Defoamer 1% ; Leveling agent 0.3%; Dispersant 1%; Anti-settling agent 0.6%; Photoinitiator 5%; Filler 3%; Matting agent 5%;

Embodiment 2

[0014] A kind of tenacity drenching coating soft light finish on the impregnated reinforced floor, this finish is a high-gloss finish, compared with embodiment 1, has adjusted gloss, the component of this soft finish and its weight ratio are: 100% UV curable resin 45%; defoamer 1.5%; leveling agent 0.5%; dispersant 0.5%; anti-sedimentation agent 0.6%; photoinitiator 5%; filler 2%;

[0015] Among the components of the above-mentioned embodiments: 100% of the UV curable resin is aliphatic epoxy acrylic resin or fatty acid modified epoxy acrylic resin, modified polyurethane acrylic resin, unsaturated polyester acrylic resin or their mixture, such as Taiwan Changxing Epoxy resins, aliphatic or aromatic polyurethane resins, polyester resins, etc. or their mixtures produced by the company, American Cytec, American Sartomer, and Jiangsu Sanmu; the monomers are acrylates, Modified acrylates or their mixtures, such as TPGDA, TMPTA, HDDA and other monomers produced by Taiwan Changxing C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com