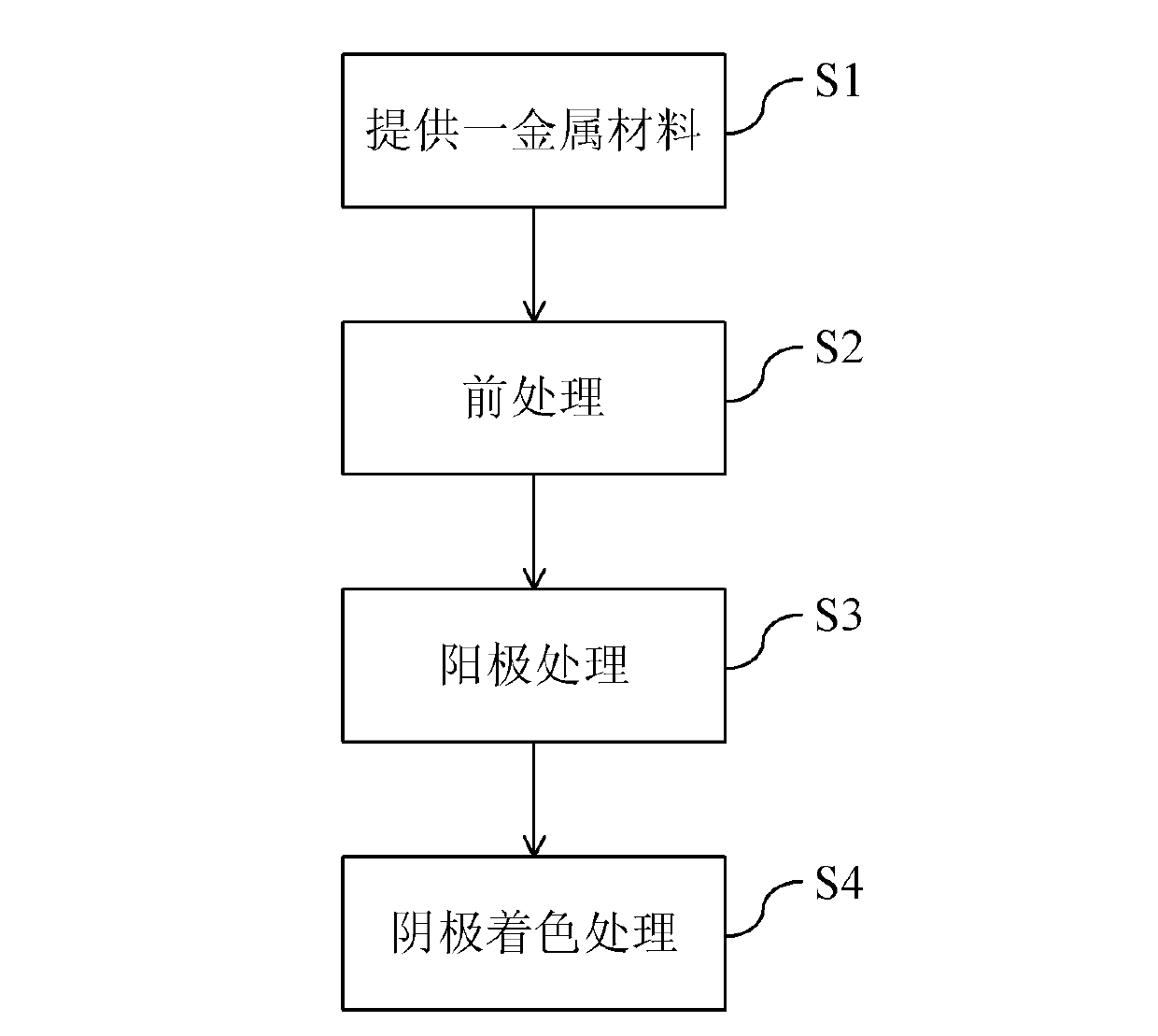

Method for whitening surface of metal material

A metal material, white technology, applied in the field of making the surface of metal materials white and coloring the surface of metal materials, can solve the problems of rare metal shells, unable to meet the texture and appearance, and loss of metal texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

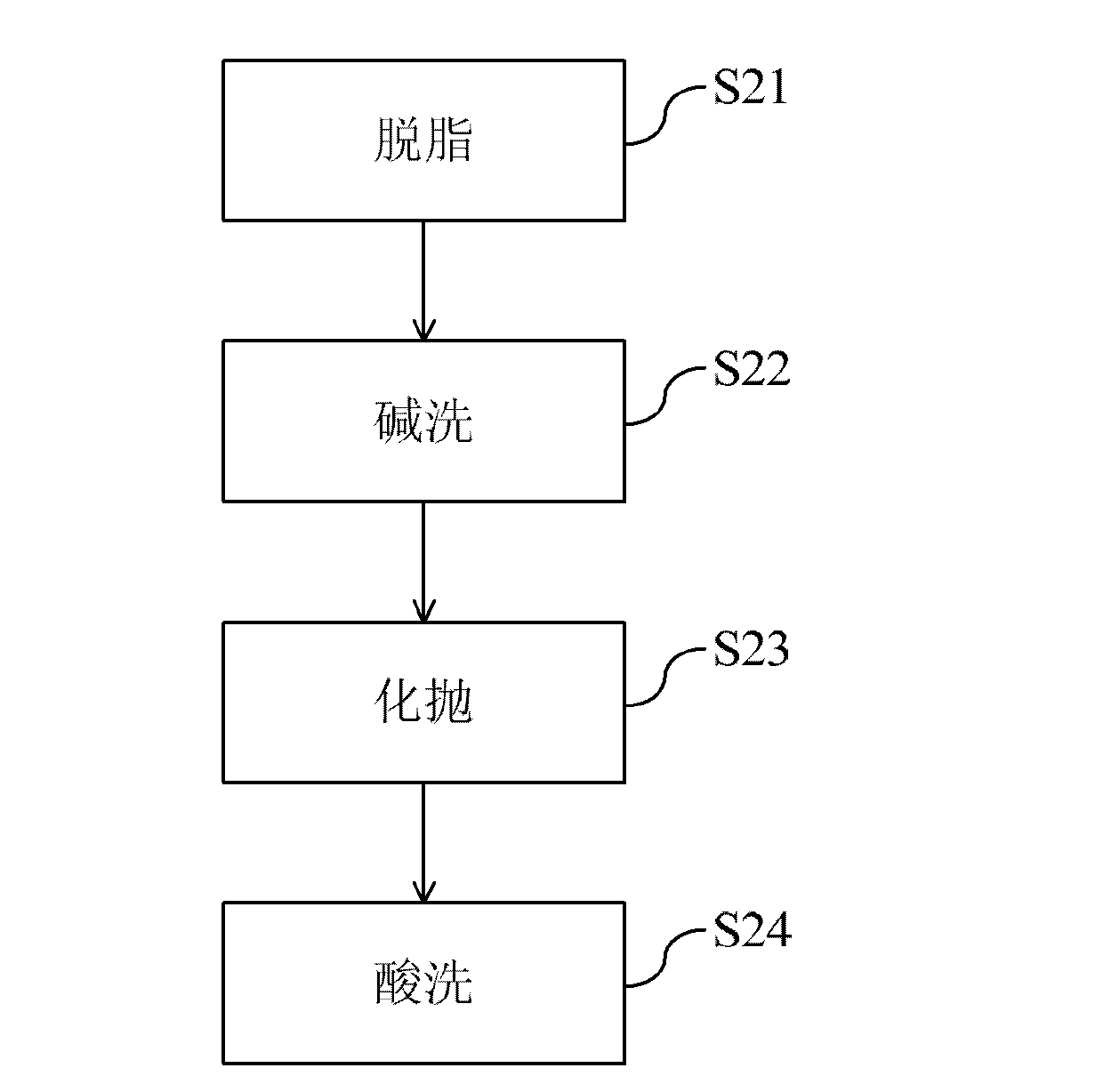

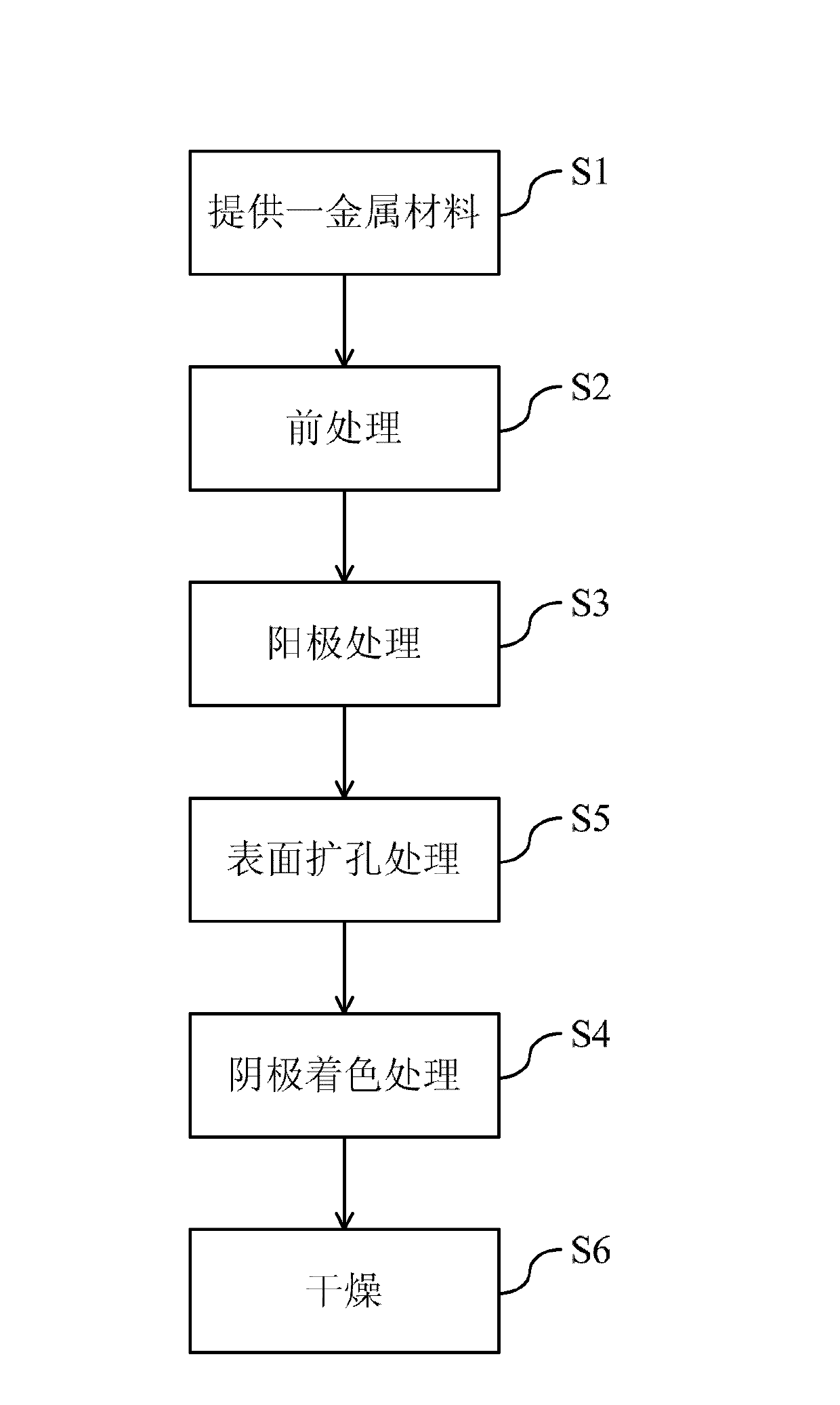

[0043] Prepare an aluminum alloy material, and subject the aluminum alloy material to pretreatment S2, which includes degreasing S21, alkali washing S22, chemical polishing S23, pickling S24, etc.; In the degreasing agent solution, after degreasing S21 at a temperature of 50°C, the metal material was washed twice with pure water at room temperature. Next, the aluminum alloy material was placed in a 200 g / L sodium hydroxide aqueous solution, and alkali washing S22 was performed at room temperature, and then the metal material was washed twice with pure water at room temperature. Here, the aluminum alloy material is placed in a phosphoric acid aqueous solution, and the chemical polishing S23 is performed at a temperature of 85° C. to 93° C., and then the metal material is washed three times with pure water at room temperature. Finally, the aluminum alloy material after chemical polishing S23 is placed in 20 milliliters / liter (mL / L) of nitric acid aqueous solution, pickling S24 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com