A2 grade EPS modified fireproof insulation board and preparation and using method thereof

A fire-proof insulation board and insulation board technology, which is applied in the direction of heat preservation, fire prevention, chemical instruments and methods, etc., can solve the problems of polystyrene foam insulation board processing factories shutting down, flammability and non-fire prevention, etc., to reduce losses and waste , increase employment, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described below in conjunction with the accompanying drawings.

[0053] The preparation method of the A2 grade EPS modified fireproof insulation board of the present invention comprises the following steps:

[0054] A. First process and modify non-fireproof foam particles into A2 grade fireproof foam particles;

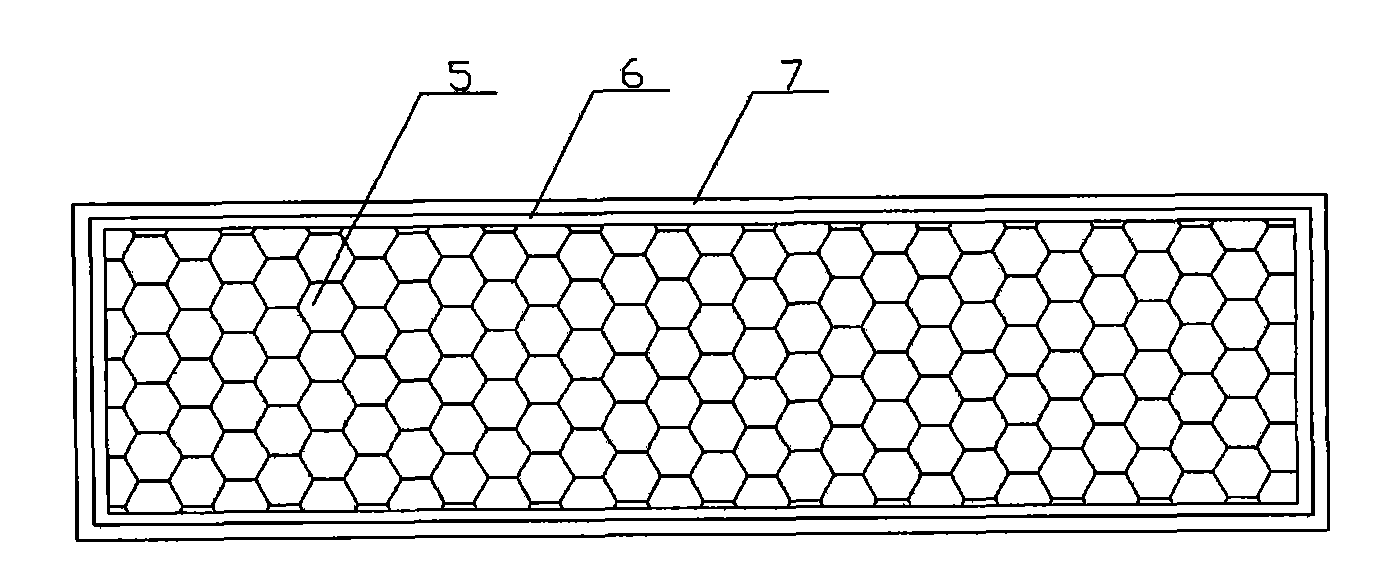

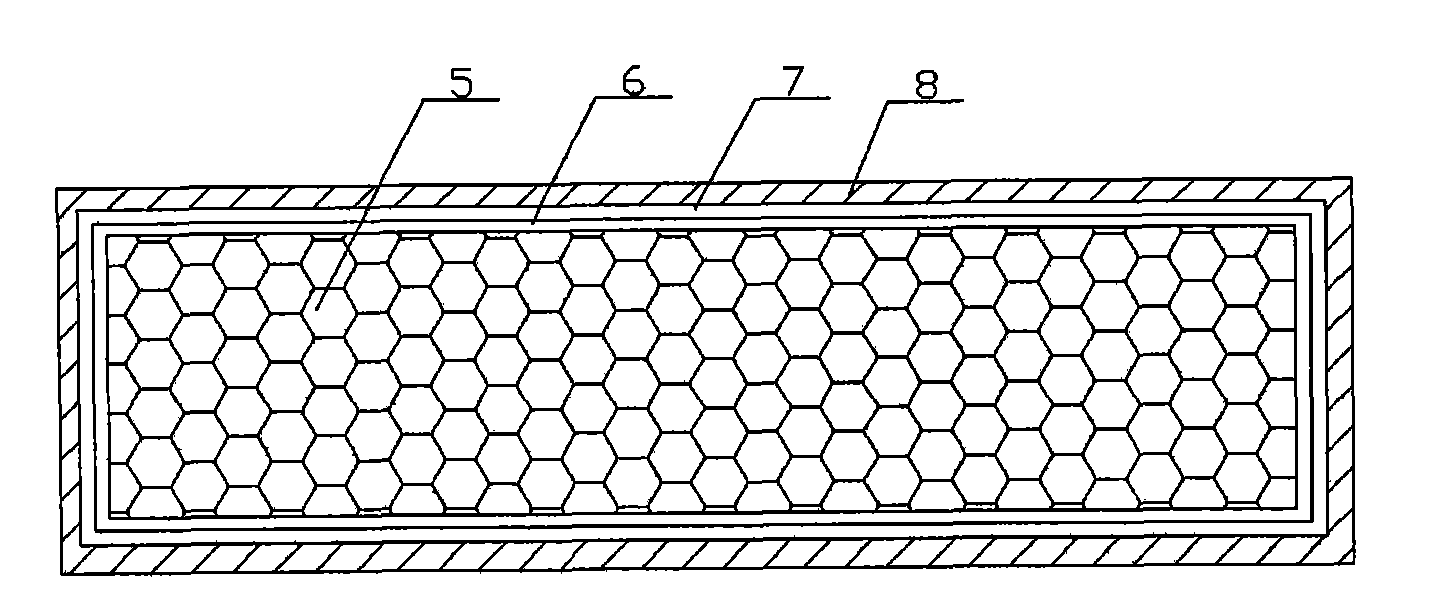

[0055] B, then process the foam granules of A2 grade fireproof into A2 grade fireproof foam board;

[0056] C. Then process the A2 grade fireproof foam board into A2 grade fireproof foam insulation board.

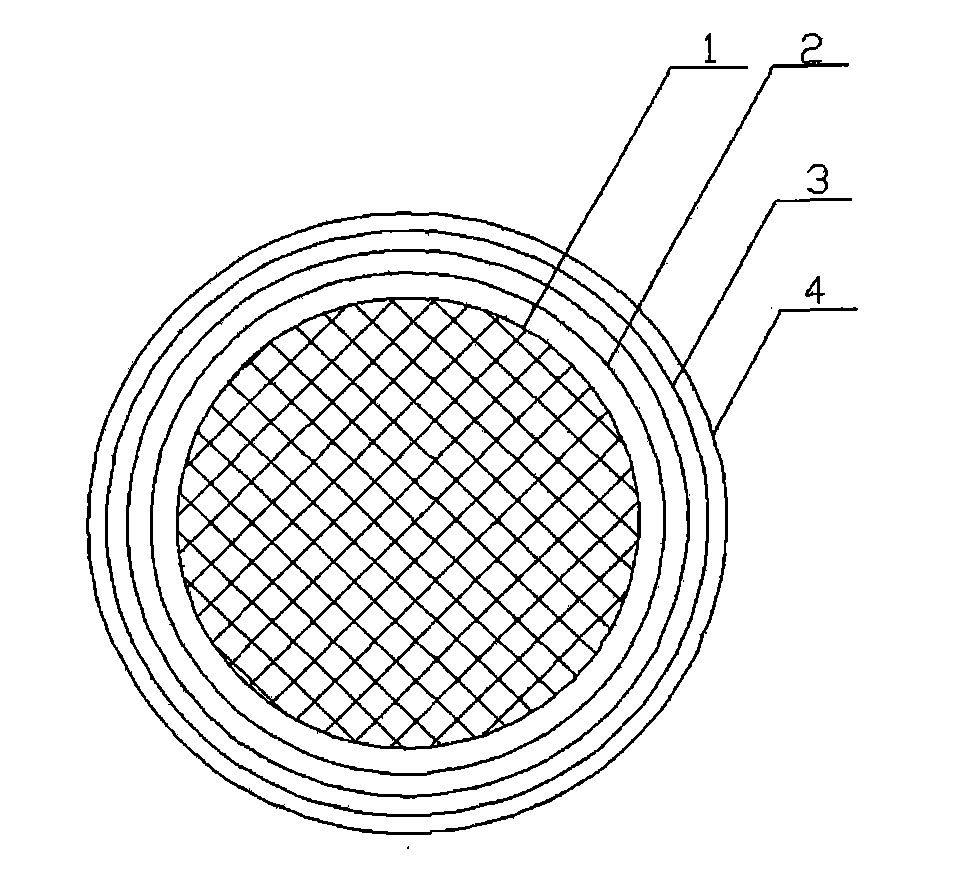

[0057] A step further comprises the steps:

[0058] The sphere surface of ordinary polystyrene foam particles is used as the original first core inner layer; outside the first core inner layer, a layer of nanocomposite fireproof additive is wrapped and infiltrated as the second fireproof middle layer;

[0059] On the outside of the second fireproof middle layer, a layer of nanocomposite flame retardant additive is wrapped and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com