A class A fireproof heat insulation polystyrene foam particle and its processing method

A technology of polystyrene foam particles, fireproof and heat preservation, applied in heat preservation, fireproof, fireproof coatings, etc., can solve the problems of flammability and fireproof, polystyrene foam processing factories shutting down and closing down, etc., to increase employment, expand the scope of use, and cost-effective Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the examples are only for illustration and do not limit the protection scope of the present invention.

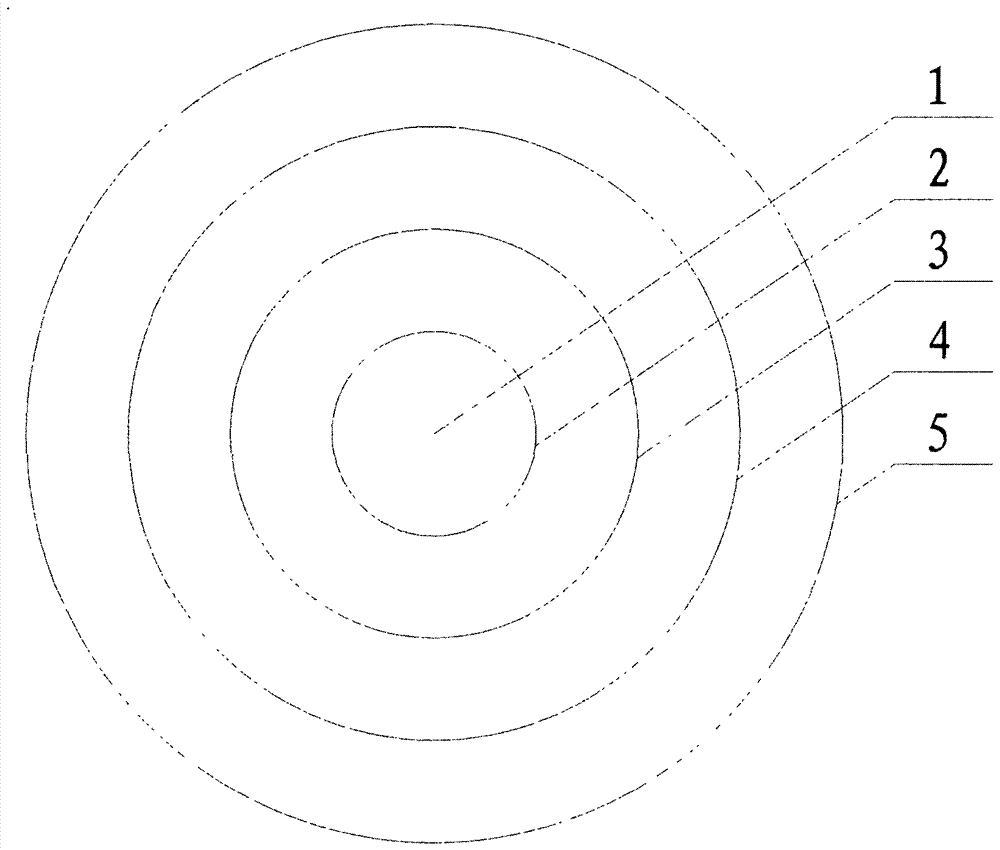

[0026] see figure 1 , the A-level fire-proof and heat-insulating polystyrene foam particles and its processing method are specifically made of ordinary commercially available polystyrene foam particles, which are modified by layering and covering with three layers of different composite additives, and according to Prepared by the processing method described below.

[0027] in:

[0028] The structure of the A-class fire-proof and heat-insulating polystyrene foam particles is as follows: use the spherical surface of a commercially available polystyrene foam particle 1 as the original first core inner layer 2; in this first core On the outside of the layer 2, wrap the second fireproof middle layer 3 coated with a layer of nanocomposite fireproofing additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com