A-grade fireproof and heat insulation sandwich plate and processing method thereof

A technology of fire prevention and heat preservation and processing methods, which is applied in the directions of heat preservation, fire prevention, chemical instruments and methods, etc., which can solve the problems of inflammability and non-fire prevention, the closure of polystyrene foam sandwich panel processing factories, etc., so as to increase employment and expand the scope of use , the effect of reducing loss and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

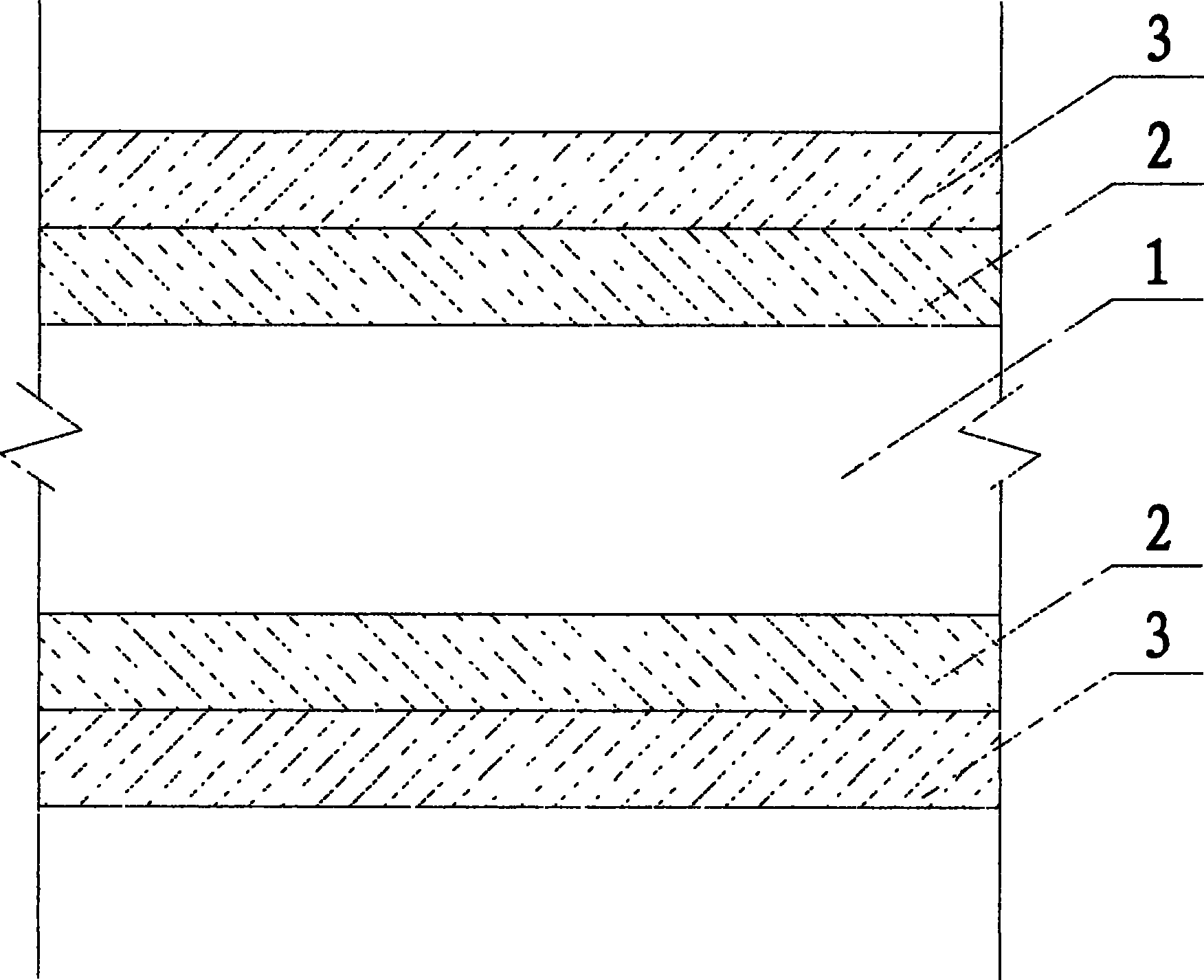

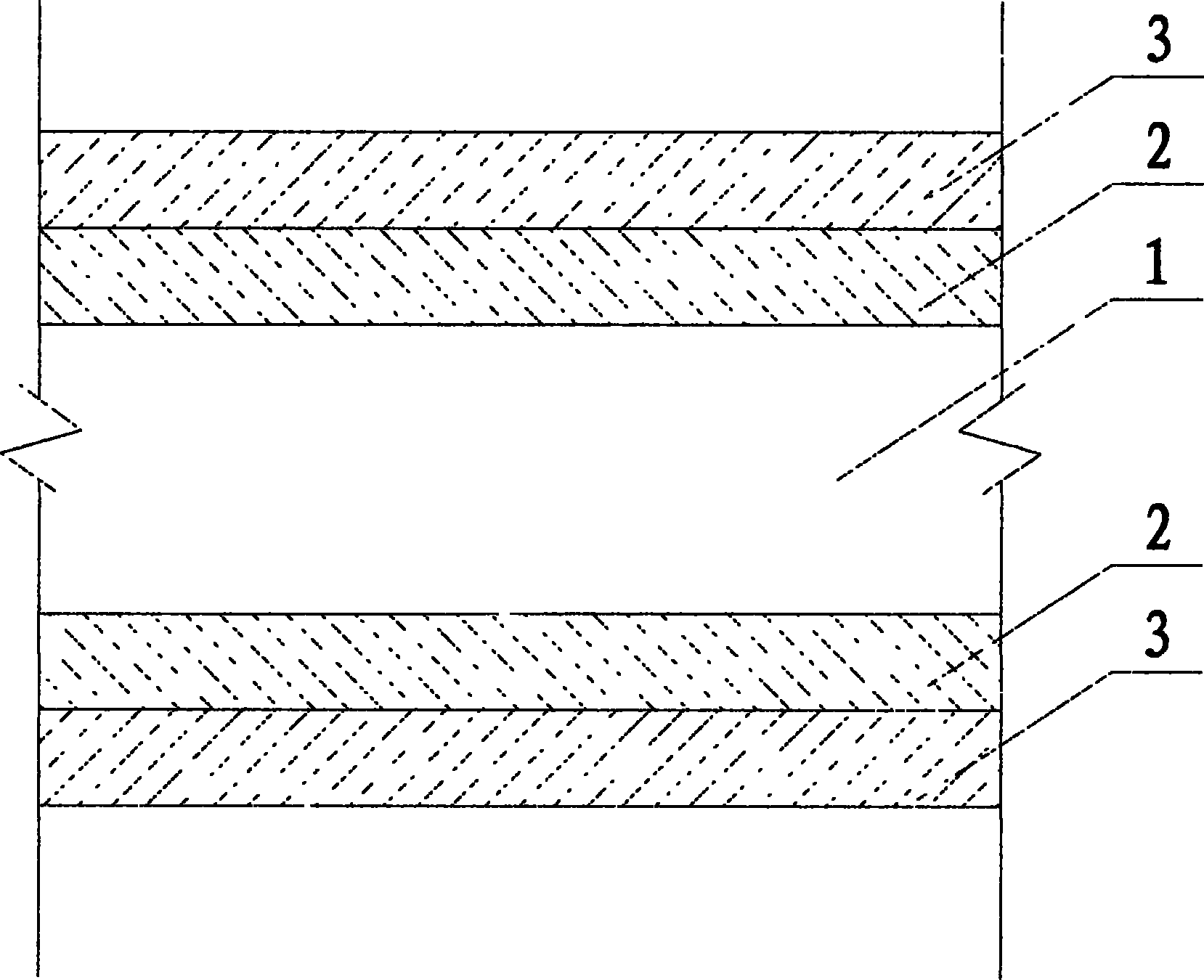

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the examples are only for illustration and do not limit the protection scope of the present invention.

[0025] see figure 1, the technical solution that the present invention can provide is implemented in this way: the purpose is to provide a sandwich panel of A-level fire-proof and heat-insulating polystyrene foam and its processing method; The fire-resistant foam particles are processed into A-level fire-resistant foam particles; the second step is to process the A-level fire-resistant foam particles into A-level fire-resistant foam boards; the third step is to convert the A-level fire-resistant foam Board, processed into A-class fireproof foam sandwich board.

[0026] For the first step, the non-fireproof foam particles are first processed into A-class fireproof foam particles. Specifically, the spherical surface of the commercially available polystyre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com