Inclined separated layer solid filling coal mining method for super thick coal seam

A technology of extra-thick coal seam and coal mining method, which is applied in the direction of filling, special mining, ground mining, etc., can solve the problems of destroying surface buildings, railways, low degree of mechanization, and destroying the ecological environment, so as to ensure safe use and mechanization Low degree, the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

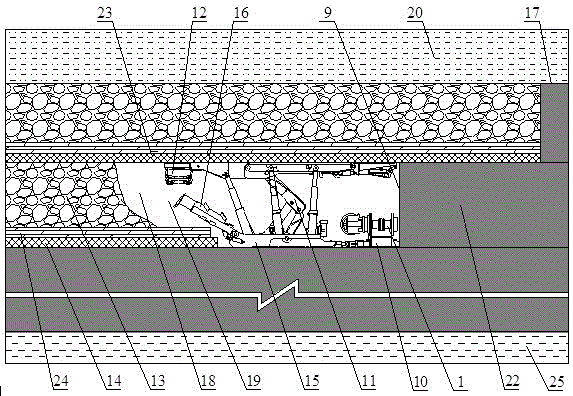

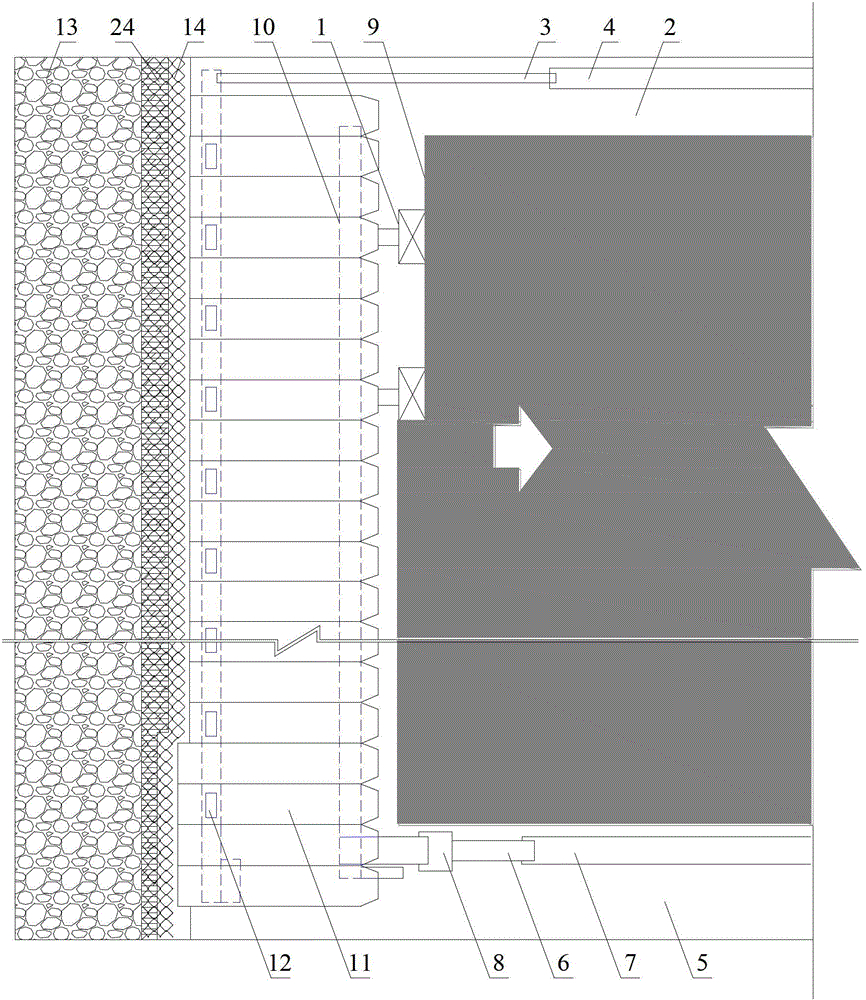

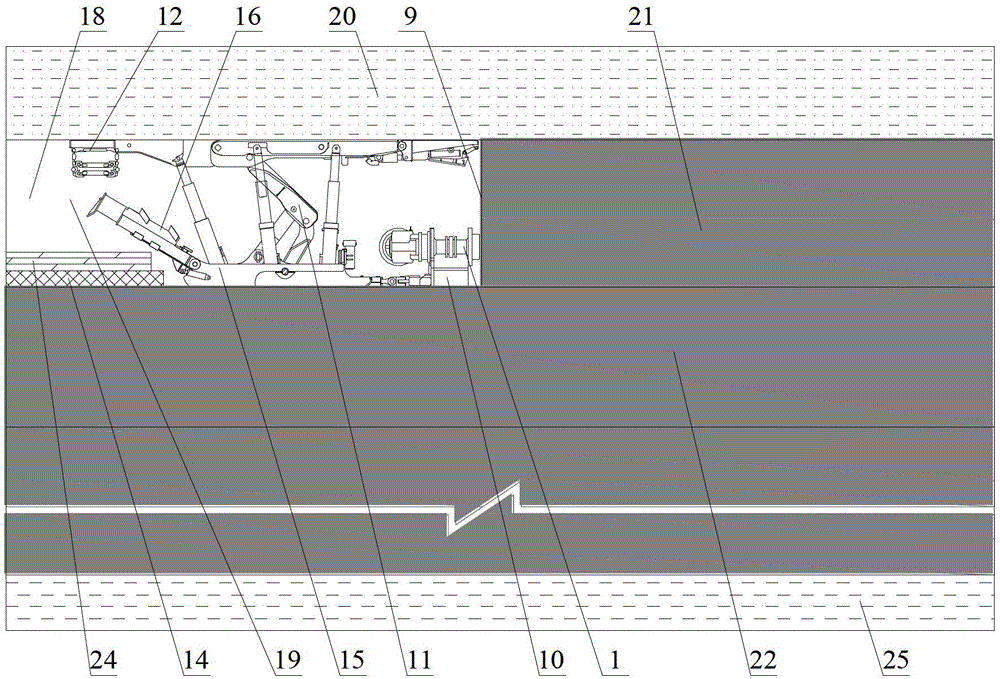

[0021] The method for coal mining with oblique stratification and solid filling in extra-thick coal seams of the present invention has the following specific steps:

[0022] a. According to the "three lower" extra-thick coal seam thickness, overlying rock structure and surface building protection level requirements, layering is carried out according to the thickness of 2.5-4.5m, and the number of inclined layered layers of the extra-thick coal seam is determined, and the down-filling is adopted by layered mining mining sequence;

[0023] b. Arrange the roadway and equipment according to the existing solid solid filling coal mining method to form a filling coal mining system, that is, dig a vertical feeding well at a suitable position on the ground, and excavate the solid filling material transportation connected with the main transportation roadway at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com