Water comprehensive characterization method for oil-containing sludge

A technology for sludge and characterization, applied in particle size analysis, particle and sedimentation analysis, measuring devices, etc., can solve the problems of complex operation, long test time, low efficiency, etc., and achieve the effect of good test repeatability and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

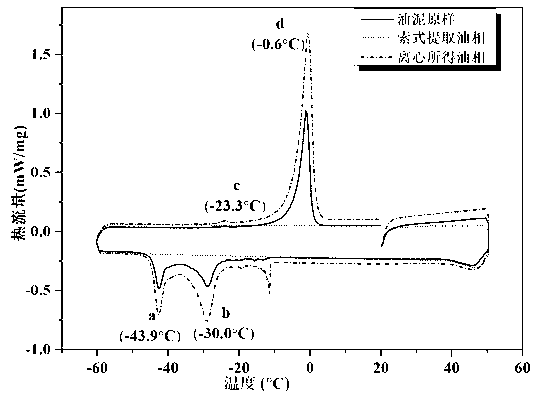

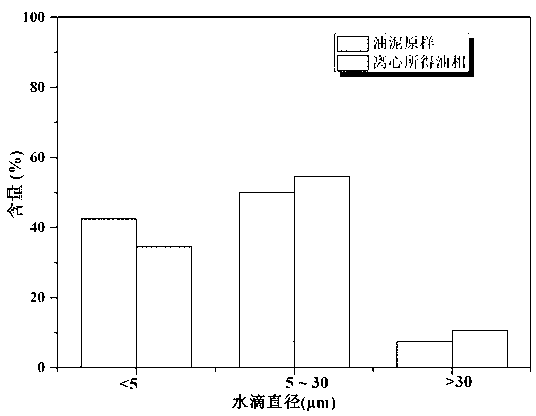

[0033] Weigh 9.3261g of oil sludge sample into an aluminum crucible, and cover the crucible lid. Put the crucible of the sample to be tested and the reference crucible into the differential scanning calorimeter, and set the temperature program according to the temperature control parameters designed in the present invention. Start the testing process. At the end of the test process, the DSC curve is obtained.

[0034] In order to describe the practicability of the present invention in detail, the oil sludge sample was extracted by Soxhlet extraction with petroleum ether (60-90° C.) until it was free of water to obtain an oil phase. The oil phase was tested in the same procedure as it was. At the end of the test, a DSC curve is obtained.

[0035] In order to describe the practicability of the present invention in detail, the sludge sample was centrifuged at 2500 rpm / min for 20 minutes to obtain the upper oil phase. The oil phase is tested according to the same procedure as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com