Dielectric constant measuring device

A technology for measuring device and permittivity, which is applied in the direction of measuring device, measuring electrical variables, measuring resistance/reactance/impedance, etc. It can solve problems such as use limitations, achieve wide applicability, high sensitivity, and improve measurement accuracy and measurement speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

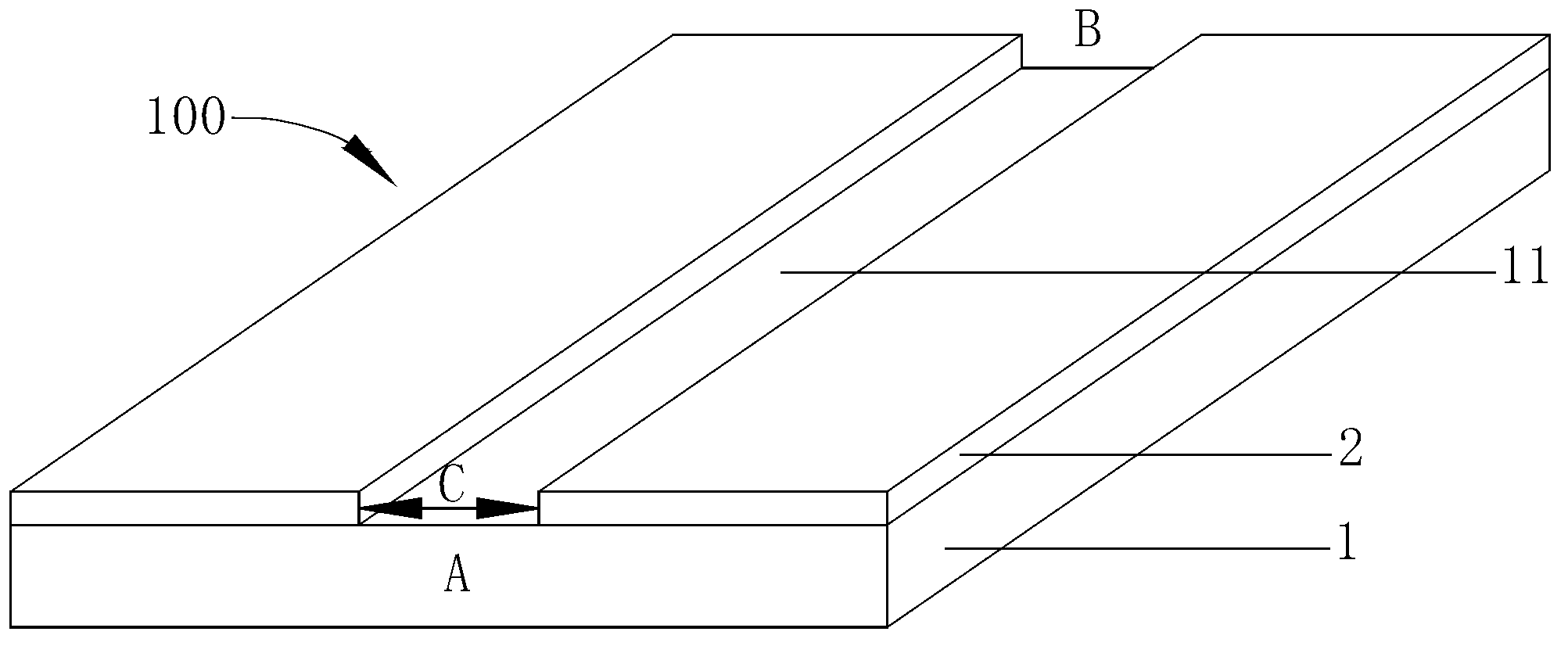

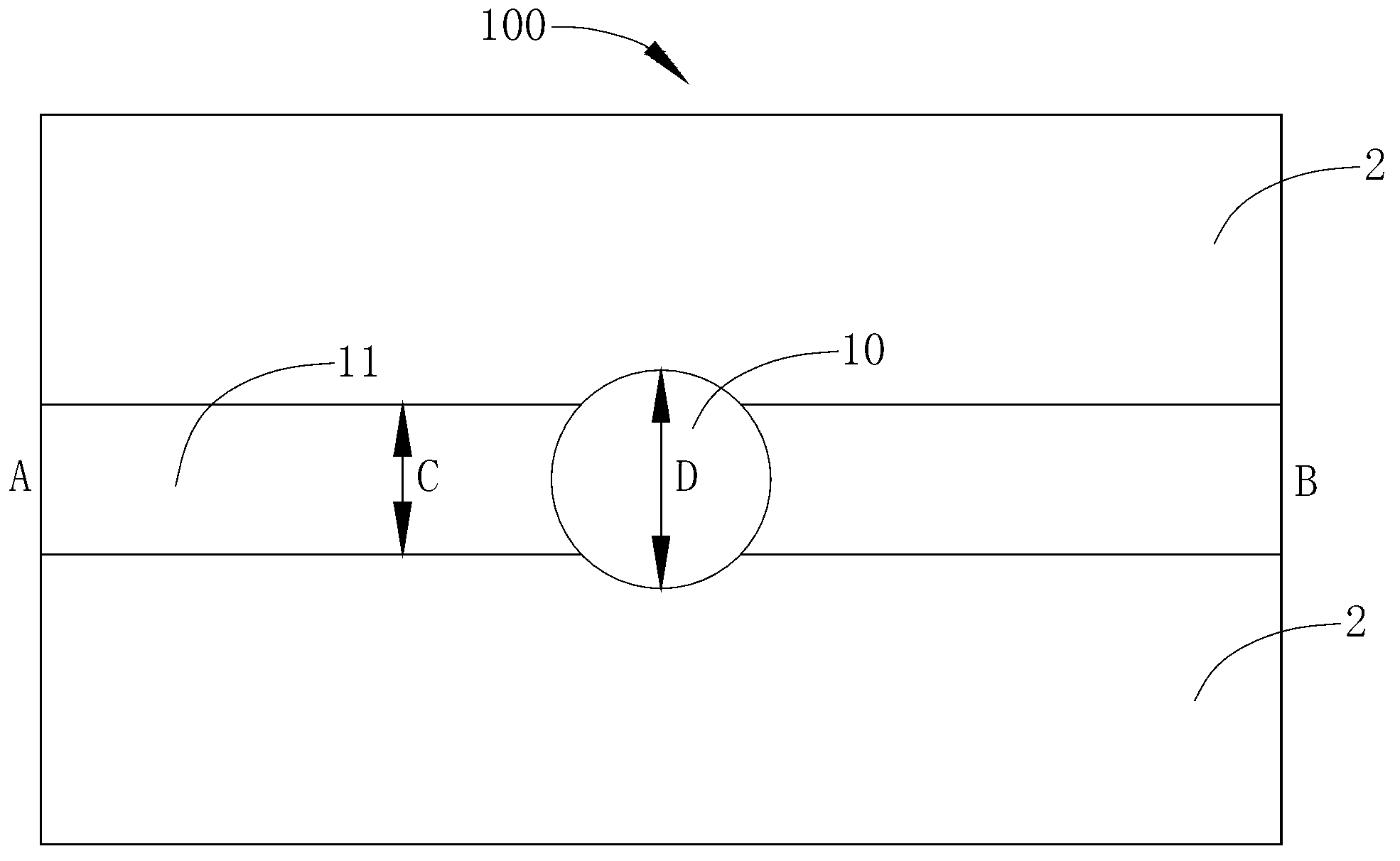

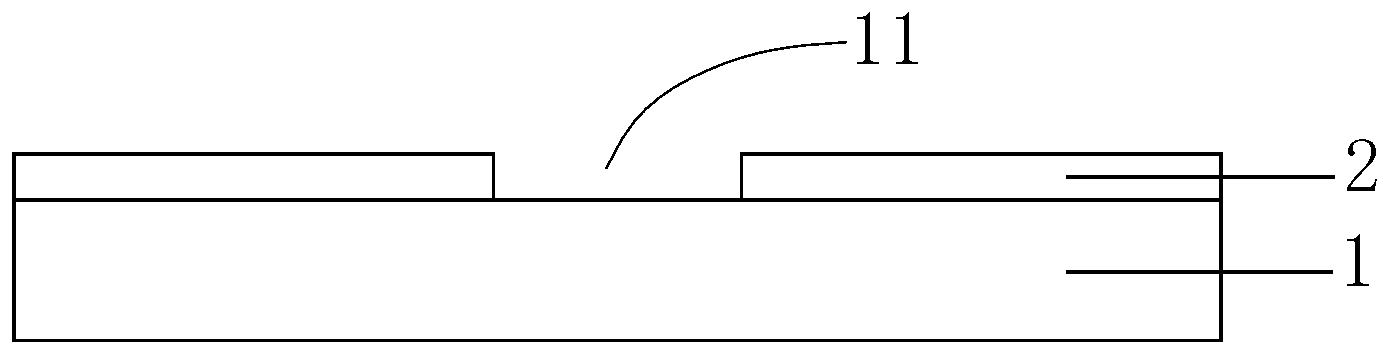

[0038] The dielectric constant measuring device of the present invention includes a slotted wire structure 100, and the two ends of A and B of the slotted wire structure 100 are respectively provided with signal interfaces for connecting testing instruments and transmitting testing signals. Such as figure 2 , image 3 with Figure 4As shown, a hole 10 is provided in the groove line structure 100 in this example, and the hole 10 is located in the groove line 11 for placing a container 12 containing the material to be tested. The slot line structure 100 is symmetrical, and the hole 10 is arranged on the center line of the slot line 11 and is located at its symmetrical center. In this example, the measured medium is a liquid, and the container 12 is a commonly used test tube. Its cross-sectional shape is circular, and the diameter D of the hole 10 is large enough, so that the measured liquid medium contained in a test tube of the same size can fully affect the groove line stru...

Embodiment 2

[0040] The groove line structure 100 of this example is the same as that of Embodiment 1, the difference is that the cross-sectional shape of the hole 10 in this example is a square, such as Figure 5 shown. As long as the side length E of the hole 10 is greater than the width C of the groove line, the measured liquid medium contained in the matched container 12 can fully affect the scattering parameters of the groove line structure 100 and meet the test requirements.

Embodiment 3

[0042] Such as Image 6 As shown, the slot line structure 100 in this example is placed in the shielding box 200 , and the two signal interfaces 201 are placed outside the side walls at both ends of the shielding box 200 . This structure has a very strong anti-interference ability, can effectively avoid the interference of external stray electromagnetic waves on the test system, and further improve the measurement accuracy. In this example, the two signal interfaces 201 include a coaxial interface and a converter, both of which adopt a coaxial interface with a characteristic impedance of 50Ω, which is a standard interface for most test instruments and signal generators. Since the coaxial interface is an unbalanced transmission interface, it does not match the balanced transmission characteristics of the slot line structure. It is necessary to use a converter between the coaxial line interface and the slot line structure for balanced / unbalanced conversion to ensure that the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com