Array substrate and manufacturing method thereof and display device

An array substrate and substrate technology, applied in optics, instruments, electrical components, etc., can solve the problems of liquid crystal displays such as greenish horizontal gray scale, lower transmittance, uneven display, etc., to improve picture quality, prevent light exposure, Improve the effect of horizontal grayscale unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

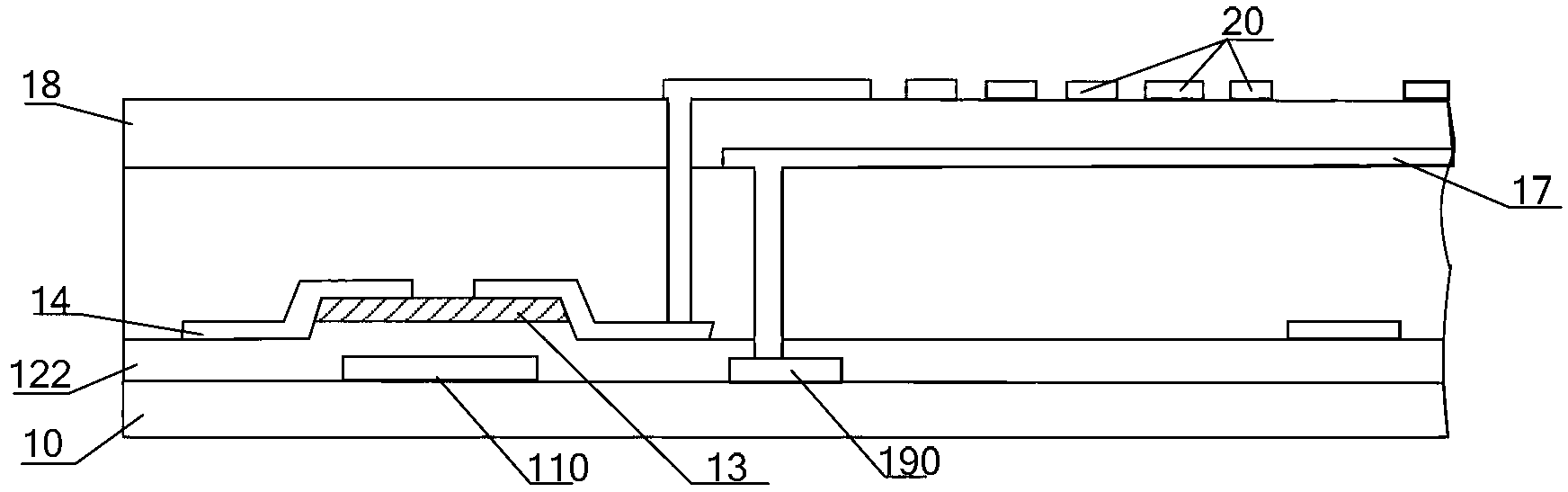

[0055] An embodiment of the present invention provides an array substrate, such as figure 2 As shown, the array substrate includes: a substrate 10, a semiconductor layer 13, a source-drain electrode layer 14, and a gate insulating layer 122 sequentially arranged on the substrate from bottom to top, and also includes:

[0056] a first gate metal layer 112 disposed on the gate insulating layer 122;

[0057] the second gate insulating layer 121 disposed under the semiconductor layer 13; and,

[0058]The second gate metal layer 111 is disposed between the second gate insulating layer 121 and the substrate 10 .

[0059] Wherein, the second gate metal layer 111 and the first gate metal layer 112 may also be made of the same material, such as one or more selected from molybdenum, aluminum, chromium, and copper. The second gate insulating layer 121 and the gate insulating layer 122 may also be made of the same material, for example, both may be silicon nitride films, and of course ...

Embodiment 2

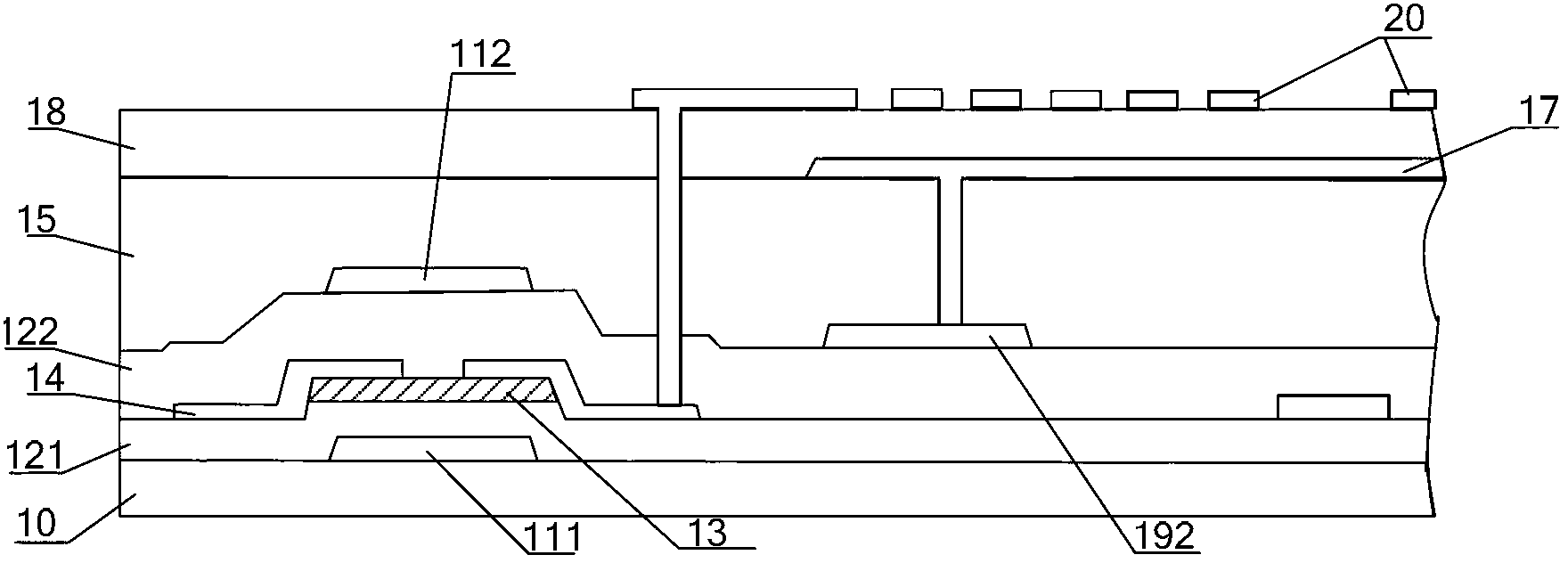

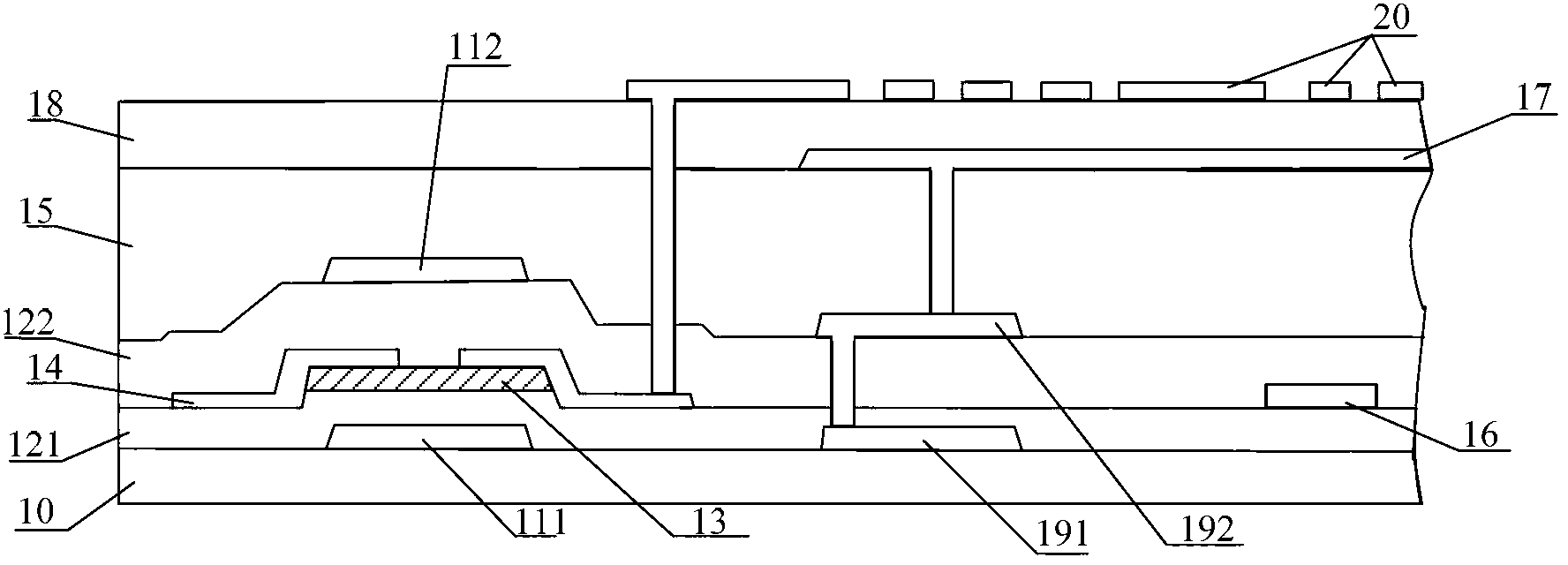

[0070] An embodiment of the present invention provides an array substrate, and figure 2 The difference of Embodiment 1 is that the array substrate further includes: a second common electrode line,

[0071] When the first common electrode line is on the same layer as the first gate metal layer, the second common electrode line is on the same layer as the second gate metal layer; when the first common electrode line is on the same layer as the first gate metal layer; When the second gate metal layer is on the same layer, the second common electrode line is on the same layer as the first gate metal layer;

[0072] The second common electrode line is connected to the first common electrode line through the insulating layer and via holes in the gate insulating layer.

[0073] In order to better understand this embodiment, a specific implementation manner of this embodiment is given here, such as image 3 As shown, the array substrate includes: a substrate 10, a second gate metal...

Embodiment 3

[0088] An embodiment of the present invention also provides a display device, which includes any one of the array substrates described in Embodiments 1 and 2. The display device may be any product or component with a display function such as a liquid crystal panel, an electronic paper, an OLED panel, a mobile phone, a tablet computer, a television set, a monitor, a notebook computer, a digital photo frame, a navigator, and the like.

[0089] The display device described in this embodiment uses the array substrate of the present invention, so it can improve the display defects such as greenish and horizontal X-talk in the display device without reducing the transmittance. , the display effect is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com