Novel high-density multilayer circuit chip flip encapsulation structure and manufacturing method

A multi-layer circuit, flip-chip packaging technology, used in circuits, semiconductor/solid-state device manufacturing, electrical components, etc. To ultra-thin package design and other issues, to achieve the effect of small thermal expansion coefficient, improved safety, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

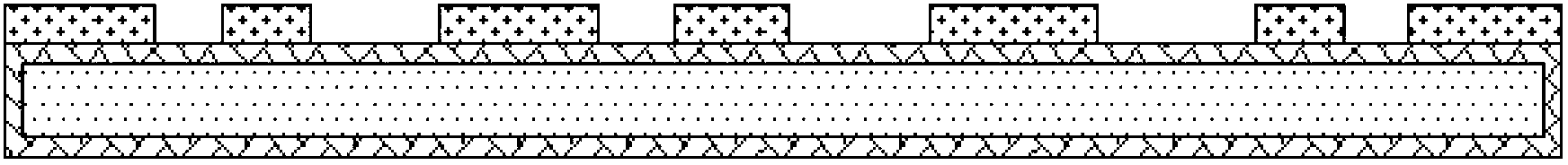

[0085] The present invention is a novel high-density multilayer circuit chip flip-chip packaging structure, which includes a circuit layer 10, a chip 2 and a circuit layer 11, and the circuit layer 10 and the circuit layer 11 are connected by copper The column layer 5 is connected, and the insulating material 6 is filled between the copper column layer 5 and the copper column layer 5 and between the circuit layer 10 and the circuit layer 10, and the circuit layer 10 and the insulating material 6 is provided with an outer ink layer 9 on the back. The outer ink layer 9 is exposed and developed to expose the outer pin 7 on the back of the circuit layer 10. The outer pin 7 is provided with a metal ball 8. The second layer of circuit Layer 11 is provided with inner pins 12 on the flip-chip soldering area 3 on the front side, and an inner ink layer 1 is arranged around the two-layer circuit layer 11 and inner pins 12, and the chip 2 is flip-chip on the front side of inner pins 12, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com