Fast recovery diode and method for manufacturing fast recovery diode

A recovery diode and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as high reverse recovery voltage, adverse effects of circuits, and reverse recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

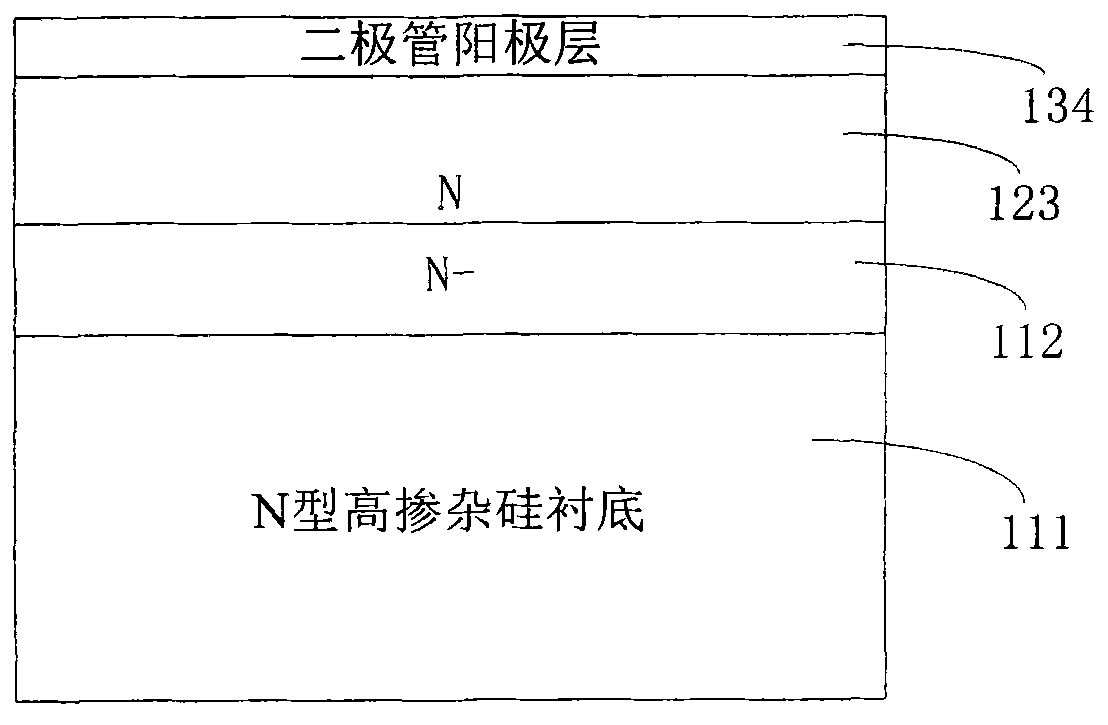

[0016] Please refer to figure 2 A preferred embodiment of the fast recovery diode of the present invention includes an N-type highly doped silicon substrate 111, a first N-type doped semiconductor layer 112, a second N-type doped semiconductor layer 123, and a diode anode layer 134 , the first N-type doped semiconductor layer 112 is located between the second N-type doped semiconductor layer 123 and the N-type highly doped silicon substrate 111 . Wherein the first N-type doped semiconductor layer 112 has a width of 5um to 50um and a doping concentration of 5e12 / cm 3 -5e14 / cm 3 . The doping concentration N of the second N-type doped semiconductor layer 123 D and the width d of the second N-type doped semiconductor layer 123 satisfy the formula (1):

[0017] where ε in formula (1) r is the dielectric constant of silicon, ε 0 is the dielectric constant of vacuum, e refers to the electric charge of a single electron, V R is the reverse bias voltage for normal operation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com