Method of processing cotton seeds

A technology for cotton seeds and seeds is applied in the field of cotton seed preparation processing technology, which can solve the problems of incapable of ensuring seed quality, seed drug coating, affecting the appearance and germination rate of seeds, affecting the germination rate, etc., so as to improve reliability and safety. , The effect of reducing the difficulty of production technology and improving the germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

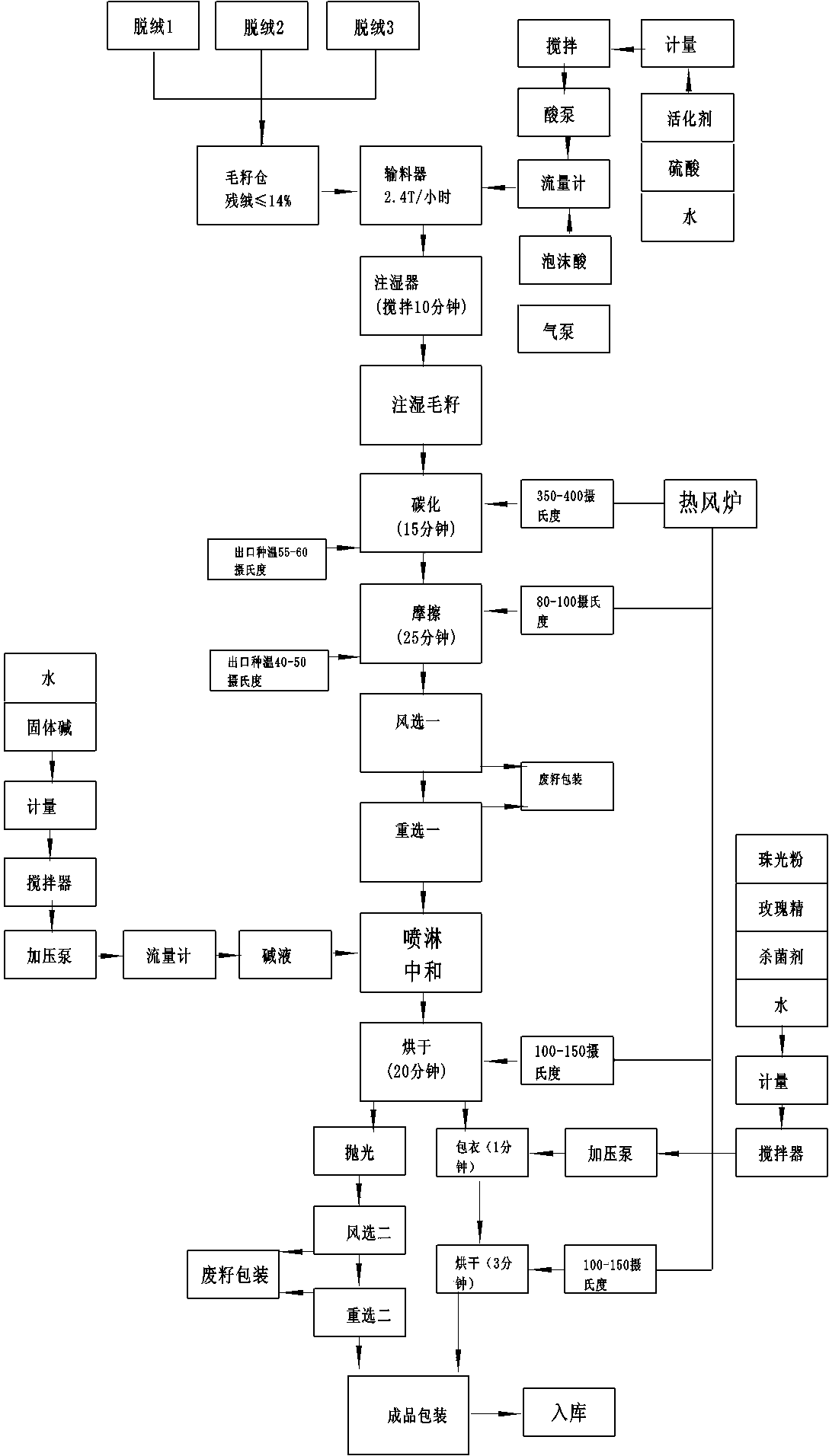

[0036] refer to figure 1 , is that the present invention is a kind of method for cotton seed processing, is characterized in that mainly comprising the following processing steps:

[0037] (1) Measure the cottonseed to be processed for standby;

[0038] (2), prepare the acid treatment solution, its main component and weight percentage are: H 2 SO4: 10%, blowing agent: 0.2%, activator: 0.15%;

[0039] (3) Put the spare acid treatment solution and cottonseed into the mixing tank evenly according to the measurement of 200L / ton of seeds, and stir for 8 to 10 minutes.

[0040] (4) Input the acid-treated cottonseed into the drying cylinder, and carbonize it at 300°C for 15 minutes. After the residual lint on the cottonseed is carbonized, when it exits the drying cylinder, 30% of the remaining velvet is slightly yellow; the carbonized cottonseed comes out The temperature at the outlet of the drying cylinder is strictly controlled at 55°C;

[0041] (5) Put the dried photoseed into...

Embodiment 2

[0048] A method for processing cotton seeds is characterized in that it mainly comprises the following process steps:

[0049] (1) Measure the cottonseed to be processed for standby;

[0050](2), prepare the acid treatment solution, its main component and weight percentage are: H 2 SO4: 13%, blowing agent: 0.3%, activator: 0.25%;

[0051] (3) Evenly input the spare acid treatment solution and cottonseed into the mixing tank according to the measurement of 230L / ton of seeds, and stir for 9 minutes.

[0052] (4) Input the acid-treated cottonseed into the drying cylinder, and carbonize it at 350°C for 13 minutes. After the residual velvet on the cottonseed is carbonized, when it exits the drying cylinder, 33% has a little yellow residual velvet; the carbonized cottonseed comes out The temperature at the outlet of the drying cylinder is strictly controlled at 58°C;

[0053] (5) Put the dried photoseed into the rubbing cylinder and rub for 30 minutes;

[0054] (6) Photoseeds ar...

Embodiment 3

[0060] A method for processing cotton seeds is characterized in that it mainly comprises the following process steps:

[0061] (1) Measure the cottonseed to be processed for standby;

[0062] (2), prepare the acid treatment solution, its main component and weight percentage are: H 2 SO4: 15%, blowing agent: 0.4%, activator: 0.3%;

[0063] (3) Evenly input the spare acid treatment solution and cottonseed into the mixing tank according to the measurement of 250L / ton of seeds, and stir for 10 minutes.

[0064] (4) Input the acid-treated cottonseed into the drying cylinder, and carbonize it at 400°C for 12 minutes. After the residual velvet on the cottonseed is carbonized, when it exits the drying cylinder, 35% of the remaining velvet is slightly yellow; the carbonized cottonseed comes out The temperature at the outlet of the drying cylinder is strictly controlled at 60°C;

[0065] (5) Put the dried photoseed into the rubbing cylinder and rub for 35 minutes;

[0066] (6) Photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com