Gelatin-CaCO3 mineral capsule shell and preparation method thereof

A technology of minerals and capsule shells, which is applied in capsule delivery, food science, non-effective ingredients of polymer compounds, etc., can solve the problems of undiscovered mineral capsule shells, shorten the disintegration time limit, have good elasticity, and reduce the use of gelatin volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

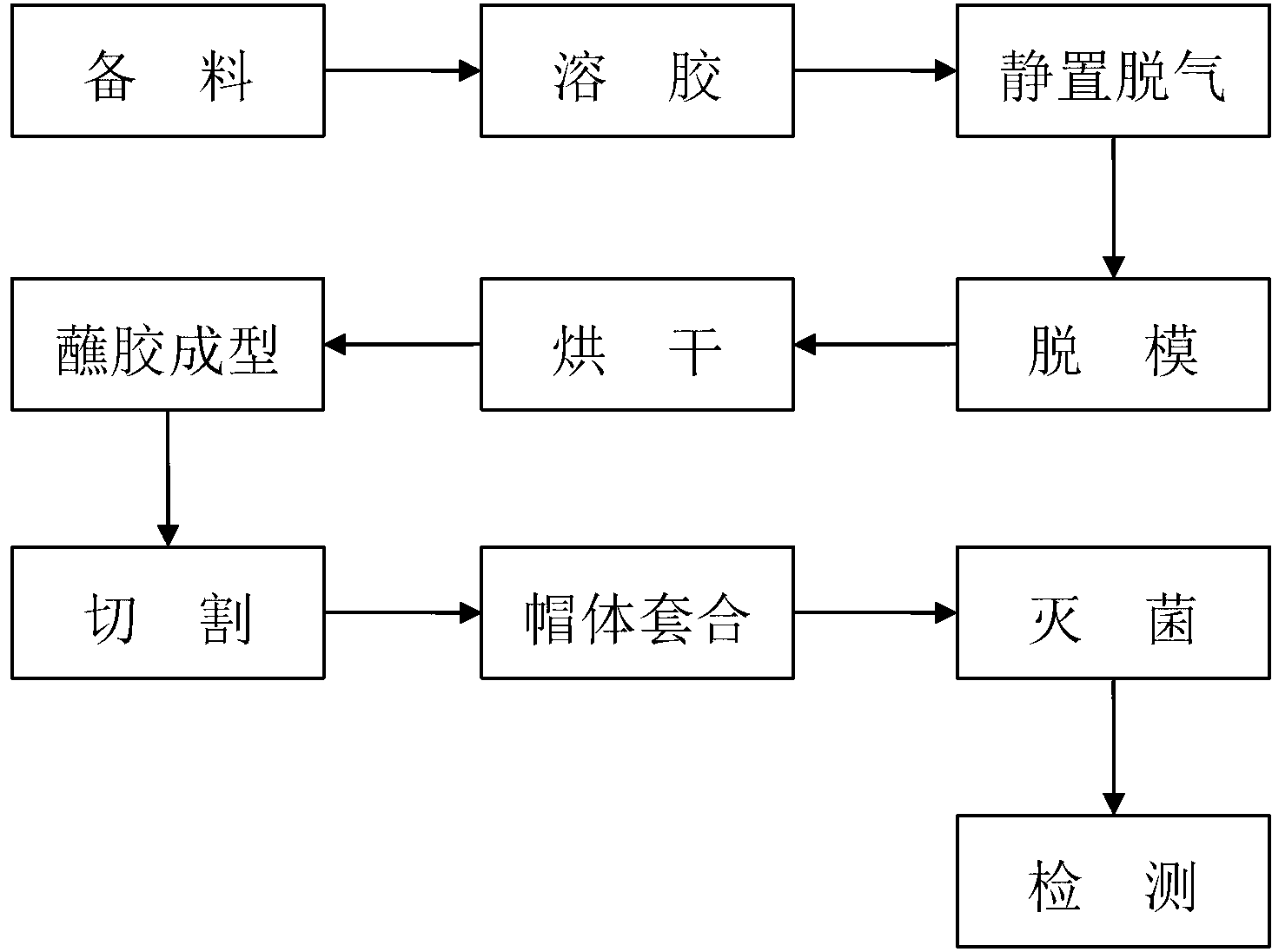

Method used

Image

Examples

Embodiment 1

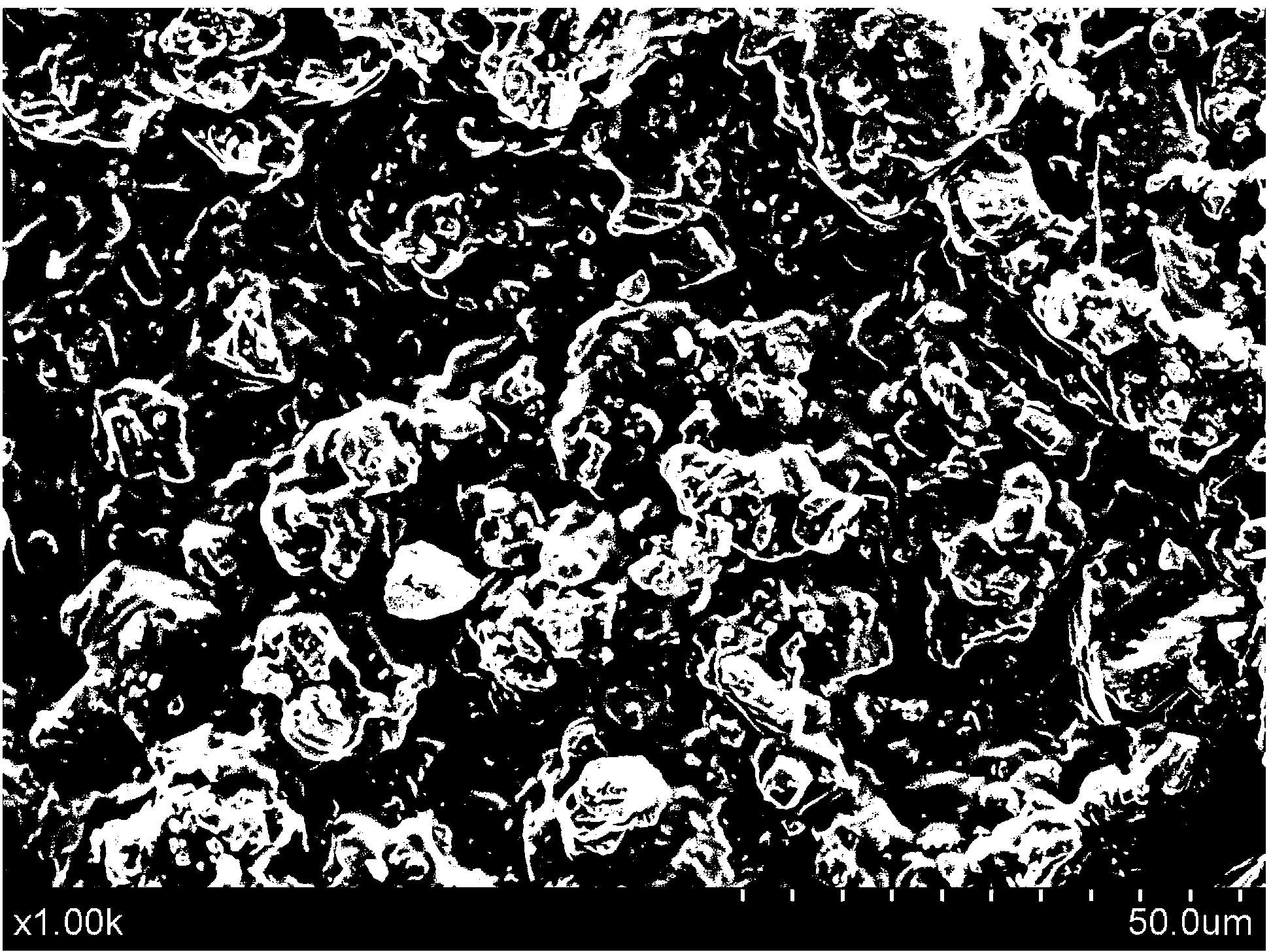

[0042] A gelatin-CaCO 3 Mineral capsule shells, whose raw materials are gelatin, CaCO 3 , plasticizer, water, consumption is respectively:

[0043] formula Dosage gelatin 27.5g CaCO 3 65.0g

[0044] Plasticizer: Glycerin 6.8g distilled water 100.0g

[0045] The preparation method of above-mentioned capsule shell, comprises the following steps:

[0046] ⑴Material preparation: Weigh 27.5g of gelatin, CaCO 3 Pour 65.0g into a beaker and mix well, take 6.8g of plasticizer, 100.0g of distilled water, pour the mixed gelatin, CaCO 3 In the beaker of the mixture, let it stand for 3-4 hours to make the gelatin fully absorb water and swell;

[0047] (2) Colloidal sol: Heat the material solution that has fully absorbed water and swelled in a constant temperature magnetic stirring water bath (about 60°C, the speed is 1500rpm), and stir fully until the gelatin is completely dissolved to form a glue solution;

[0048] ⑶ Static degassin...

Embodiment 2

[0054] A gelatin-CaCO 3 Mineral capsule shell, its main raw materials are gelatin, CaCO 3 , plasticizer, water, consumption is respectively:

[0055] formula Dosage gelatin 30.0g CaCO 3 60.0g Plasticizer: Glycerin 7.5g distilled water 100.0g

[0056] The preparation method of above-mentioned capsule shell, comprises the following steps:

[0057] ⑴Material preparation: Weigh 30.0g of gelatin, CaCO 3 Pour 60.0g into a beaker and mix well. Measure 7.5g of plasticizer, 100.0g of distilled water, pour into the mixed gelatin, CaCO 3 In the beaker of the mixture, let it stand for 3-4 hours to make the gelatin fully absorb water and swell;

[0058](2) Colloidal sol: Heat the material solution that has fully absorbed water and swelled in a constant temperature magnetic stirring water bath (about 60°C, the speed is 1500rpm), and stir fully until the gelatin is completely dissolved to form a glue solution;

[0059] ⑶ Static degassing: use th...

Embodiment 3

[0065] A gelatin-CaCO 3 Mineral capsule shell, its main raw materials are gelatin, CaCO 3 , plasticizer, water, consumption is respectively:

[0066] formula Dosage gelatin 28.0g CaCO 3 70.0g Plasticizer: Sorbitol 8.5g distilled water 110.0g

[0067] The preparation method of above-mentioned capsule shell is the same as embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com