Maleic anhydride oil modified aqueous alkyd resin, and environmentally-friendly paint prepared through using it

A technology of alkyd resin and maleic anhydride oil, applied in the field of coatings, can solve the problems of loss of luster, dryness, thickening, and poor quality, and achieve the effect of solving poor drying properties and reducing the cost of paint making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

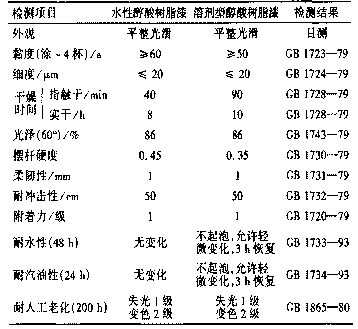

Image

Examples

Embodiment 1

[0032] Preparation of maleic anhydride oil:

[0033] Put 15 parts of linseed oil and 5 parts of maleic anhydride into a four-neck flask, raise the temperature to 200-220 degrees while stirring and keep it warm for 6-10 hours to pass the test, and take it out of the pot for later use.

Embodiment 2

[0035] Preparation of maleic anhydride oil modified waterborne alkyd resin:

[0036] Put 35 parts of soy oil acid, 5 parts of benzoic acid, 18 parts of pentaerythritol, 18 parts of dimethylolpropionic acid, and 30 parts of phthalic anhydride into the pot, stir and heat up to 170-190 degrees for one hour, then heat up to 200-230 degrees After the viscosity is greater than 380 seconds, add 10 parts of maleic anhydride oil and 20 parts of butyl ether prepared above, stir and keep warm at 135 degrees for one hour, then add 8 parts of triethylamine for neutralization for 30 minutes, then add 35 parts of tap water to obtain maleic anhydride oil modification Waterborne alkyd resin.

Embodiment 3

[0037] Embodiment 3: the environment-friendly alkyd paint prepared by maleic anhydride oil modified waterborne alkyd resin

[0038] Maleic anhydride oil modified water-based alkyd resin 65 parts

[0039] 30 parts of titanium dioxide

[0041] 65 parts of tap water

[0042] 0.5 parts of water-based bentonite

[0043] 0.3 parts of water-based defoamer

[0044] 0.5 parts of water-based dispersant

[0045] 0.5 parts of water-based leveling agent

[0046] 0.4 parts of environmentally friendly cobalt acetoacetate

[0047] Technological process: Put the above raw materials except the environment-friendly cobalt acetoacetate into a sand mill, grind until the fineness is less than 30 microns, then add the environment-friendly cobalt acetoacetate drier to obtain the maleic anhydride oil-modified water-based alcohol Environmentally friendly alkyd paint prepared from acid resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com