Inorganic air-drying solid lubricant for coupling

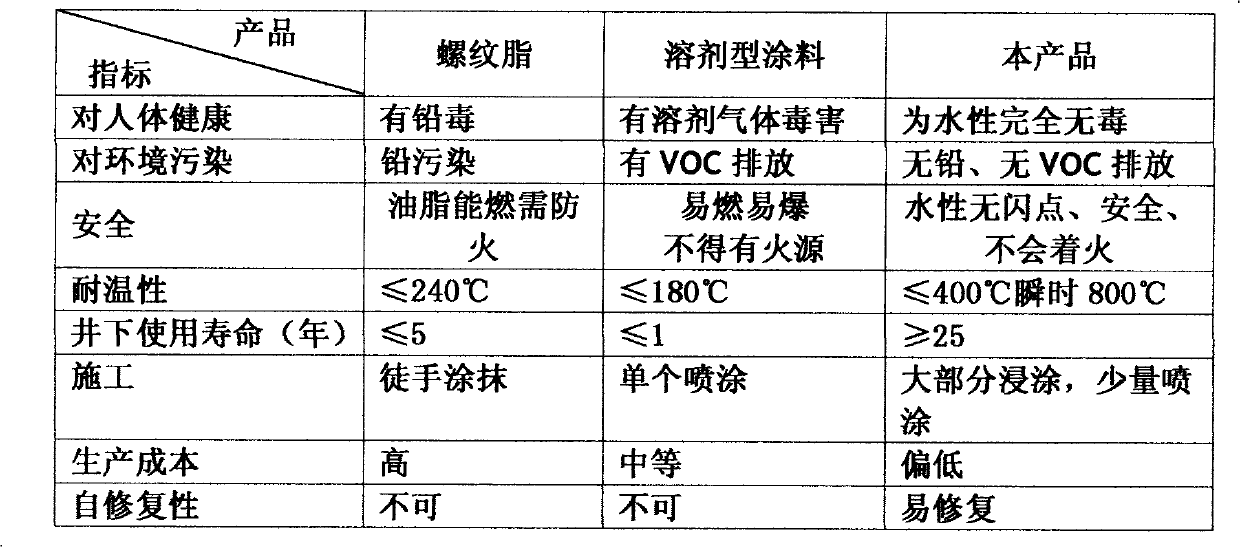

A solid lubricant and solid lubrication technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of low product cost performance, poor quality, and large environmental pollution, so as to improve product cost performance and competitive advantage, quality is difficult to control, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take 202g of potassium silicate with an M of 3.7 and put it into an ultrasonic machine tank, add 20ml of water, heat to 55°C, add 88g of silica sol dropwise under the power-on condition, and react for 15 minutes after adding it for about 25 minutes, then add 3.5 methyltrimethoxysilane dropwise. g, add 3.5g of stabilizer 204 silicone oil, react for 45min after the addition, and then dropwise add 4.5g of modified silicone to prepare a potassium silicate solution with a modulus of 5.6.

[0032] Take 200g of the above potassium silicate solution, add 22g of 1000 mesh zinc powder and 9g of graphite, mix evenly, and spray on the petroleum coupling to obtain a long-life inorganic self-drying solid lubricant for coupling. According to the test, the number of unbuckles is more than 12 times, while the current lubricating grease is up to 6 times, that is, the anti-sticking performance has been more than doubled.

Embodiment 2

[0034] Take 100g of potassium silicate with an M of 3.7 and put it into an ultrasonic machine tank, add 10ml of water, heat to 60°C, add 50g of silica sol dropwise under the condition of starting up, and react for 15 minutes after adding it for about 20 minutes, then add γ-aminopropyl trimethyl Add 2g of oxysilane, react for 15 minutes after adding, then add 2g of stabilizer NP-10 and 2g of silicone acrylic resin to prepare a potassium silicate solution with a modulus of 6.

[0035] Take this solution as the base material, take 100g of it and add 20g of 1000 mesh zinc powder, molybdenum disulfide (MoS 2 ) 10g, mix well and then dilute with water to obtain a long-life inorganic self-drying solid lubricant for couplings. The lubricant is dip-coated on the coupling, and a solid lubricating film is obtained after curing. The coupling was subjected to the buckle-up test, and the number of buckle-ups was 13 times, four times greater than the 3 times stipulated by API.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com