Light emitting diode (LED) with composite transparent conducting layer and preparation method thereof

A technology of light emitting diodes and transparent conductive layers, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as inability to effectively eliminate total reflection, and achieve the effects of low production cost, high controllability, and improved light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0054] The light emitting diode according to the first embodiment of the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings.

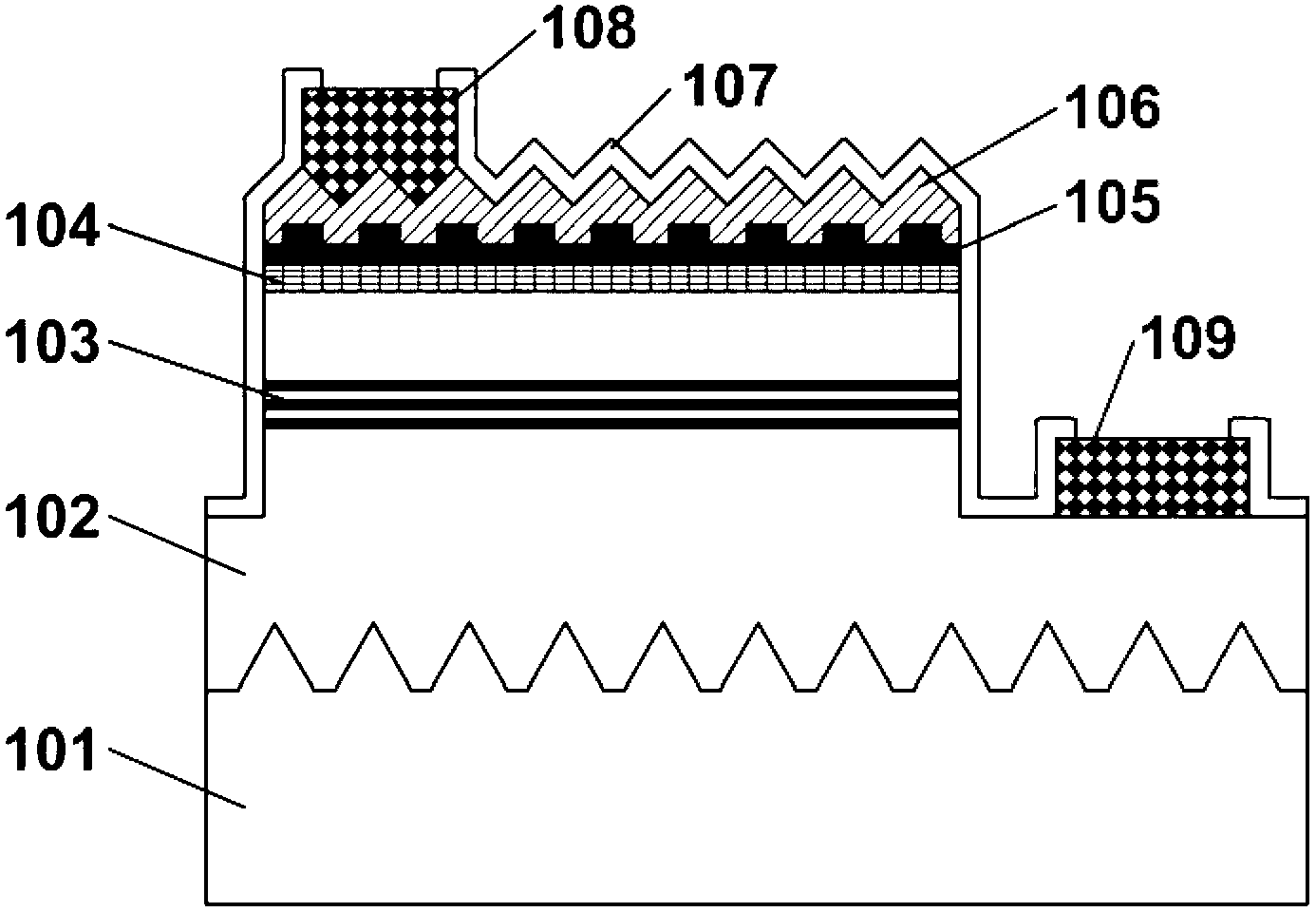

[0055] The light emitting diode according to the first embodiment includes a Group-III nitride epitaxial layer, a composite transparent conductive layer, a transparent passivation layer, and a metal electrode, and the composite transparent conductive layer is located between the Group-III nitride epitaxial layer and the transparent passivation layer. between. The doped titanium oxide layer is formed on the III-group nitride epitaxial layer, and the indium tin oxide layer covers the doped titanium oxide layer and forms a composite multi-layer structure with the doped titanium oxide layer to form a convex-concave mosaic, so that the light-emitting diode can be improved. light extraction efficiency.

[0056] Specifically, such as figure 1 As shown, the light emitting diode of this...

no. 2 example

[0070] Hereinafter, a light emitting diode having a composite transparent conductive layer and a manufacturing method thereof according to a second embodiment of the present invention will be described in detail with reference to the accompanying drawings. The light-emitting diode and its manufacturing method according to the second embodiment are similar to the light-emitting diode and its manufacturing method according to the first embodiment, and the similarities will not be repeated here, and only the second embodiment and the first embodiment will be described The differences are described in detail.

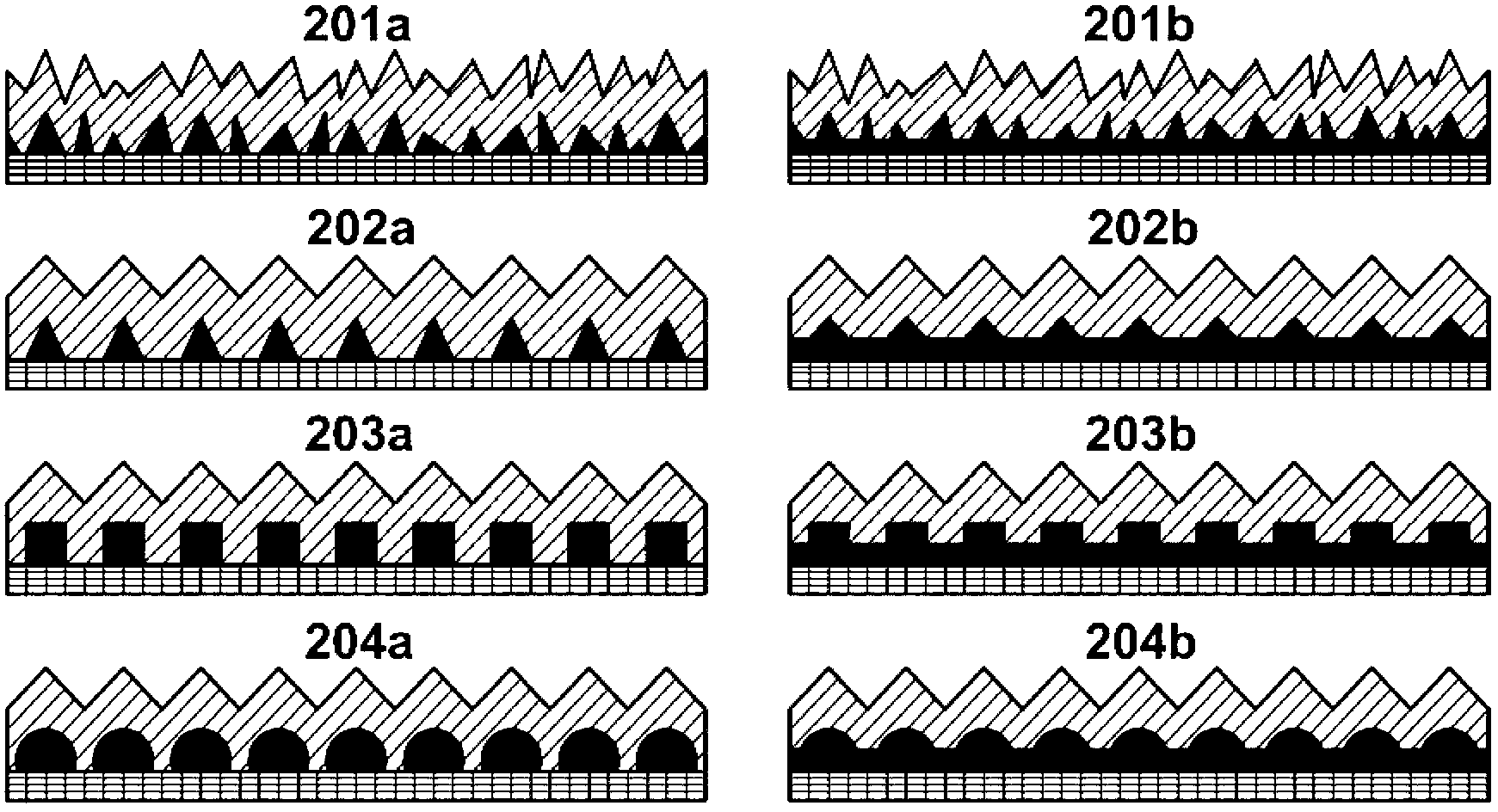

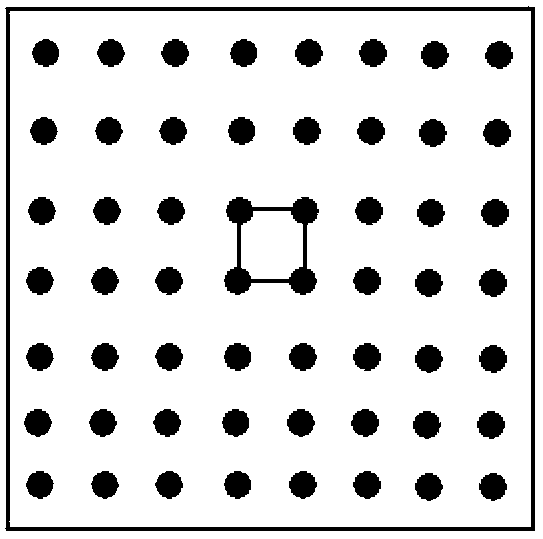

[0071] In this embodiment, the doped titanium oxide layer 105 and the indium tin oxide layer 106 are arranged periodically in space, thereby forming a two-dimensional photonic crystal structure, wherein the lattice constant is, for example, between 100 nanometers and 1 micrometer. The lattice type of the two-dimensional photonic crystal structure of the composite transparen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com