Pollution-resistant chlorine polyamide-resistant reverse osmosis composite membrane and preparation method thereof

A technology of reverse osmosis composite membrane and chlorine-resistant polyamide, which is applied in the fields of semi-permeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., and can solve problems such as poor chlorine resistance and anti-oxidation performance and increased operating costs , achieve anti-pollution performance and chlorine resistance performance improvement, simple preparation method, good anti-pollution and chlorine resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

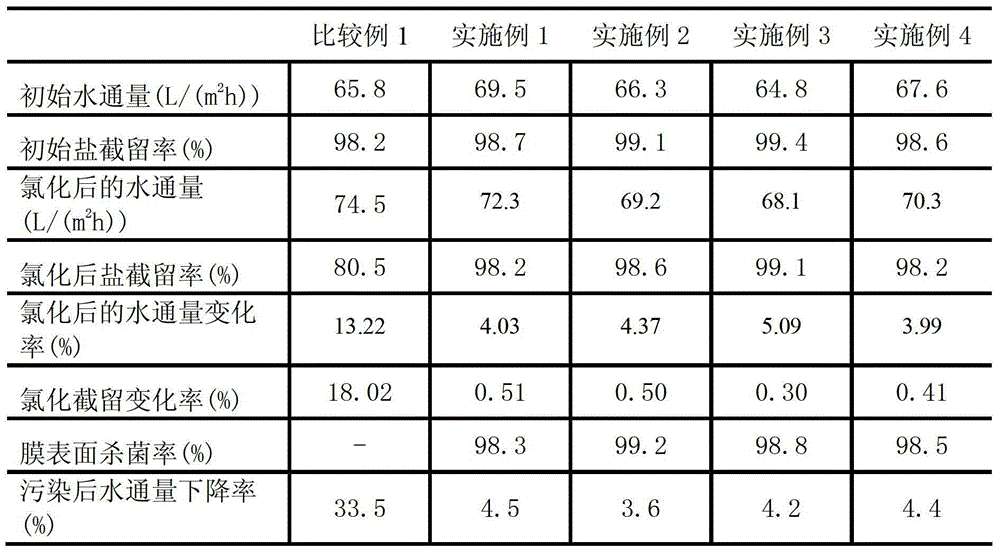

[0023] A method for preparing an anti-pollution chlorine-resistant polyamide reverse osmosis composite membrane, comprising the steps of:

[0024] (1) Soak the polyamide layer in the raw material polyamide reverse osmosis composite membrane, which plays the role of desalination, in an aqueous solution of isopropanol with a pH of 10.0, a temperature of 50°C, and a concentration of 10.0 wt% for 100 minutes, take it out and wash it with pure water ;

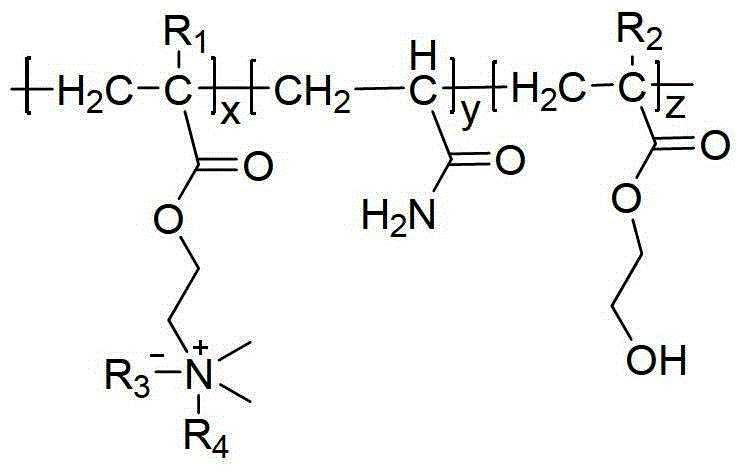

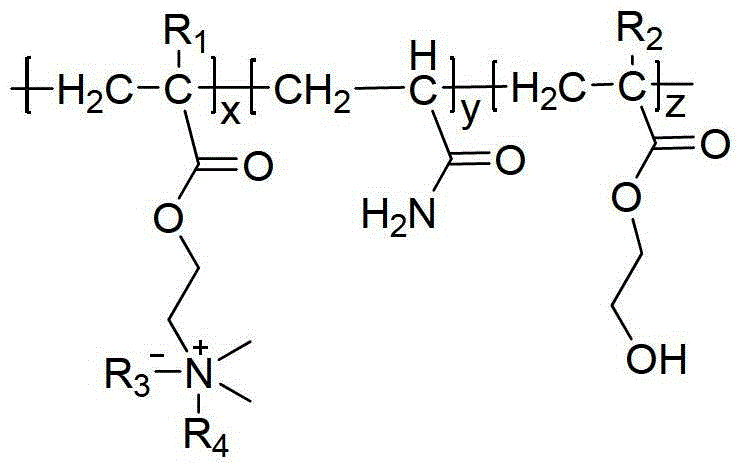

[0025] (2) Soak the desalination polyamide layer in the raw material polyamide reverse osmosis composite membrane treated in step (1) in a mixed solution with a pH of 3.0 and a temperature of 50°C for 30 minutes, take it out and place it in a 100°C refrigerator Keep it in the oven for 100 minutes, take it out and wash it with pure water to obtain an anti-pollution chlorine-resistant polyamide reverse osmosis composite membrane; the mixed solution contains 5.0wt% anti-pollution chlorine-resistant hydrophilic polymer terpolymer in wat...

Embodiment 2

[0030] A method for preparing an anti-pollution chlorine-resistant polyamide reverse osmosis composite membrane, comprising the steps of:

[0031] (1) Soak the polyamide layer in the raw material polyamide reverse osmosis composite membrane, which plays the role of desalination, in an aqueous solution of isopropanol with a pH of 8.0, a temperature of 100°C, and a concentration of 2.0wt% for 200 minutes, take it out and wash it with pure water ;

[0032] (2) Soak the desalination polyamide layer in the raw polyamide reverse osmosis composite membrane treated in step (1) in a mixed solution with a pH of 1.0 and a temperature of 20°C for 60 minutes, take it out and place it in a 30°C refrigerator Keep in the oven for 150 minutes, take it out and wash it with pure water to obtain an anti-pollution chlorine-resistant polyamide reverse osmosis composite membrane; the mixed solution is water containing 0.01wt% anti-pollution chlorine-resistant hydrophilic polymer terpolymer and a so...

Embodiment 3

[0036] A method for preparing an anti-pollution chlorine-resistant polyamide reverse osmosis composite membrane, comprising the steps of:

[0037] (1) Soak the polyamide layer in the raw material polyamide reverse osmosis composite membrane, which plays the role of desalination, in an aqueous solution of isopropanol with a pH of 9.0, a temperature of 60°C, and a concentration of 15.0 wt% for 80 minutes, take it out and wash it with pure water ;

[0038] (2) Soak the desalination polyamide layer in the raw material polyamide reverse osmosis composite membrane treated in step (1) in a mixed solution with a pH of 4.0 and a temperature of 60°C for 20 minutes, take it out and place it in a refrigerator at 120°C Keep it in the oven for 80 minutes, take it out and wash it with pure water to obtain an anti-pollution and chlorine-resistant polyamide reverse osmosis composite membrane; the mixed solution is water containing 4.0wt% anti-pollution and chlorine-resistant hydrophilic polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com