A method for low-temperature modification of c/c composite materials by ultrasonic-ultraviolet method

A technology of composite materials and carbon composite materials, which is applied in the field of low-temperature modification of C/C composite materials by ultrasonic-ultraviolet method, can solve the problems of C/C composite materials such as degradation of mechanical and thermal properties, protection failure, and volatile compounds. Achieve the effect of low raw material price, improved anti-oxidation performance, and improved anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Take the 2D-carbon / carbon composite material used in aircraft brake pads and process it into 10×10×3mm 3 The small cubes were polished and chamfered on the surface, then cleaned with absolute ethanol and deionized water in an ultrasonic generator, and dried in an oven for later use;

[0022] 2) Mix the analytically pure tri-n-butyl borate and absolute ethanol at a volume ratio of 1:6, and keep stirring, record as A;

[0023] 3) Mix A with analytically pure acetic acid at a volume ratio of 2.5:1 and keep stirring to form a sol precursor, which is denoted as B;

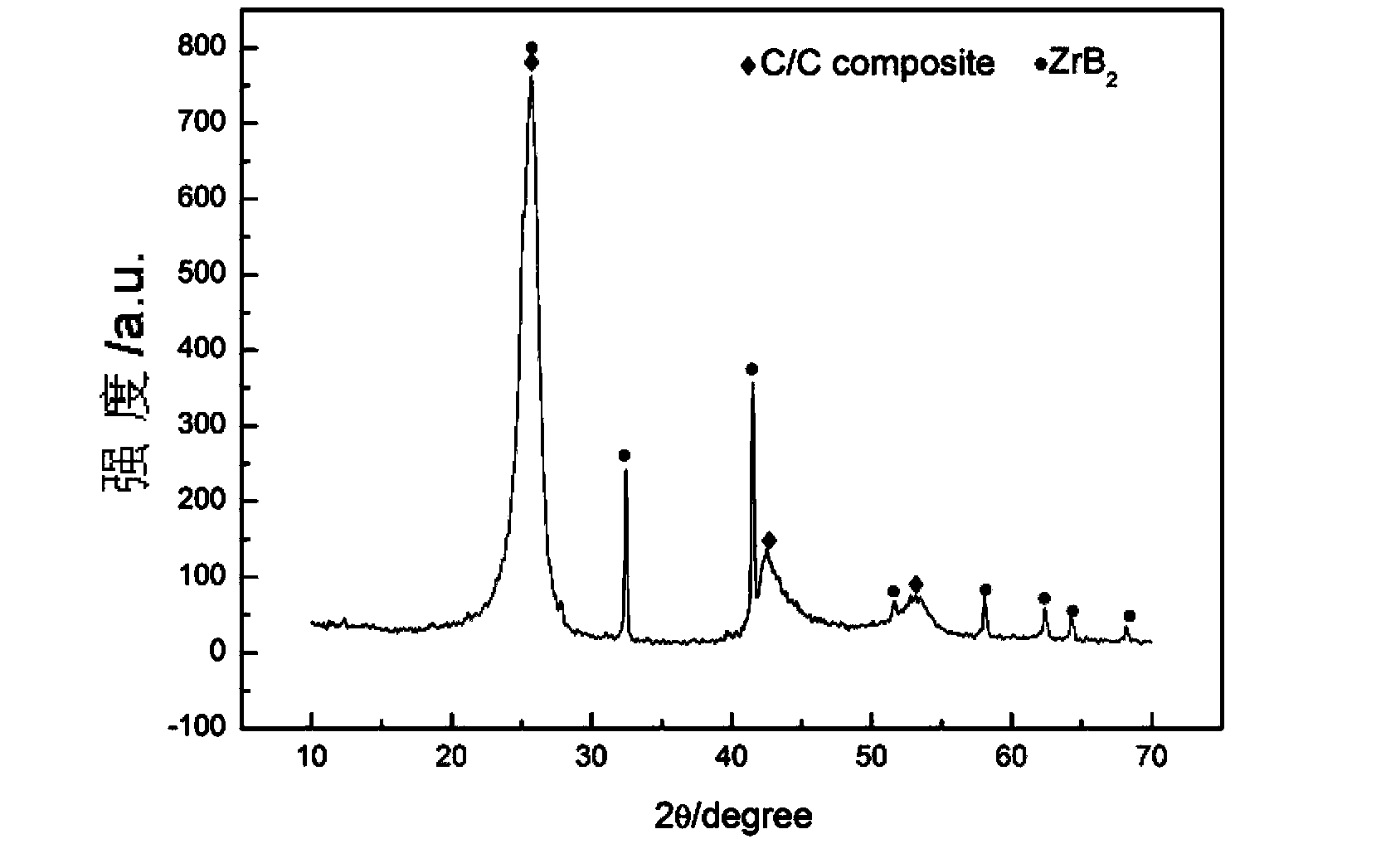

[0024] 4) Add 10% ZrB of B mass to B 2 Powder, stir for 1-2 hours to form a uniform suspension C;

[0025] 5) Pour the suspension C into a four-neck round bottom flask, and place the 2D-carbon / carbon composite material in the suspension C, and put the equipped four-neck round bottom flask into a UWave-1000 microwave·ultraviolet· The ultrasonic trinity synthesis extraction reaction instrument is fixed, and t...

Embodiment 2

[0028] 1) Take the 2D-carbon / carbon composite material used in aircraft brake pads and process it into 10×10×3mm 3 The small cubes were polished and chamfered on the surface, then cleaned with absolute ethanol and deionized water in an ultrasonic generator, and dried in an oven for later use;

[0029] 2) Mix the analytically pure tri-n-butyl borate and absolute ethanol at a volume ratio of 1:4, and keep stirring, record as A;

[0030] 3) Mix A with analytically pure acetic acid at a volume ratio of 2:1, and keep stirring to form a sol precursor, which is denoted as B;

[0031] 4) Add 10% ZrB of B mass to B 2 Powder, stir for 1-2 hours to form a uniform suspension C;

[0032] 5) Pour the suspension C into a four-neck round bottom flask, and place the 2D-carbon / carbon composite material in the suspension C, and put the equipped four-neck round bottom flask into a UWave-1000 microwave·ultraviolet· The ultrasonic trinity synthesis extraction reaction instrument is fixed, and th...

Embodiment 3

[0035] 1) Take the 2D-carbon / carbon composite material used in aircraft brake pads and process it into 10×10×3mm 3 The small cubes were polished and chamfered on the surface, then cleaned with absolute ethanol and deionized water in an ultrasonic generator, and dried in an oven for later use;

[0036] 2) Mix the analytically pure tri-n-butyl borate and absolute ethanol at a volume ratio of 1:3, and keep stirring, record as A;

[0037]3) Mix A with analytically pure acetic acid at a volume ratio of 4:1 and keep stirring to form a sol precursor, which is denoted as B;

[0038] 4) Add 10% ZrB of B mass to B 2 Powder, stir for 1-2 hours to form a uniform suspension C;

[0039] 5) Pour the suspension C into a four-neck round bottom flask, and place the 2D-carbon / carbon composite material in the suspension C, and put the equipped four-neck round bottom flask into a UWave-1000 microwave·ultraviolet· The ultrasonic trinity synthesis extraction reaction instrument is fixed, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com