Imidazole ionic liquid with dual functions of oxidation and temperature control and synthetic method of ionic liquid

A technology of ionic liquids and synthesis methods, applied in chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, organic chemistry, etc., can solve problems that are not involved in specific properties, and achieve the effect of a large adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] ionic liquid 1 The synthesis steps are as follows. The structural formula is shown in the following formula:

[0048]

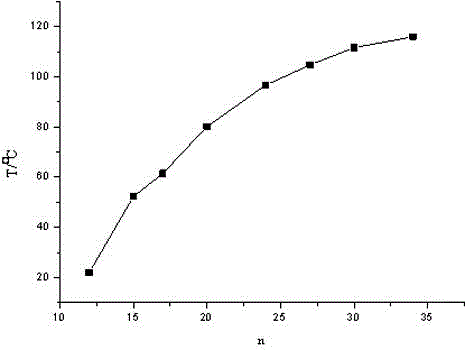

[0049] 1. Synthesis of intermediate (I): Accurately weigh 1.7 g of imidazole and 10 mL of n-hexane, add it to a 100 mL autoclave, and refrigerate it in the refrigerator for at least 2 h; then add 20 mL of Ethylene oxide, sealed, with N 2 The air in the kettle was replaced 4 times. After stirring at room temperature for 2 h, the reaction was carried out at 60 °C for 4 h. Cool down, deflate, and open the kettle, transfer the reaction mixture into a 250 mL three-necked flask, wash the kettle wall with absolute ethanol, and transfer the washing solution into the three-necked flask together. The n-hexane and absolute ethanol were evaporated under reduced pressure to constant weight to obtain 17.95 g of intermediate (I). According to the product weight gain method, the average degree of polymerization of the intermediate (I) is calculated to be n=15....

Embodiment 2

[0053] ionic liquid 2 The synthesis steps are as follows. The structural formula is shown in the following formula:

[0054]

[0055] 1. Synthesis of intermediate (I): Accurately weigh 1.7 g of imidazole and 10 mL of n-hexane, add it to a 100 mL autoclave, and refrigerate it in the refrigerator for at least 2 h; then add 25 mL of Ethylene oxide, N for sealing 2 The air in the kettle was replaced 4 times. Stir at room temperature for 2 h, then react at a constant temperature of 60 °C for 4 h, lower the temperature, release gas, and open the kettle, transfer the reaction mixture into a 250 mL three-necked flask, wash the kettle wall with absolute ethanol, and transfer the washing solution into a three-necked flask. Under reduced pressure, n-hexane and absolute ethanol were distilled off to constant weight to obtain 23.30 g of intermediate (I). According to the product weight gain method, the average polymerization degree n=20 of the intermediate (I) was calculated.

[00...

Embodiment 3

[0059] ionic liquid 3 The synthesis steps are as follows. The structural formula is shown in the following formula:

[0060]

[0061] 1. Synthesis of intermediate (I): Accurately weigh 1.7 g of imidazole and 10 mL of n-hexane, add it to a 100 mL autoclave, and place it in the refrigerator for at least 2 h; then add 60 mL of Ethylene oxide, N for sealing 2 The air in the kettle was replaced 4 times. Stir at room temperature for 2 h, then react at a constant temperature of 60 °C for 4 h, lower the temperature, release gas, and open the kettle, transfer the reaction mixture into a 250 mL three-necked flask, wash the kettle wall with absolute ethanol, and transfer the washing solution into a three-necked flask. The n-hexane and absolute ethanol were evaporated under reduced pressure to constant weight to obtain 39.58 g of intermediate (I). According to the product weight gain method, the average polymerization degree n=34 of the intermediate (I) was calculated.

[0062] 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com