A self-assembly preparation method of electrospun bead string fibers

A bead string fiber and self-assembly technology, applied in the fields of materials and chemistry, can solve the problems of limited water collection and directional transmission effects, ignoring the self-assembly performance of spider silk, etc., achieve obvious water collection performance, stable fiber properties, and broaden the application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

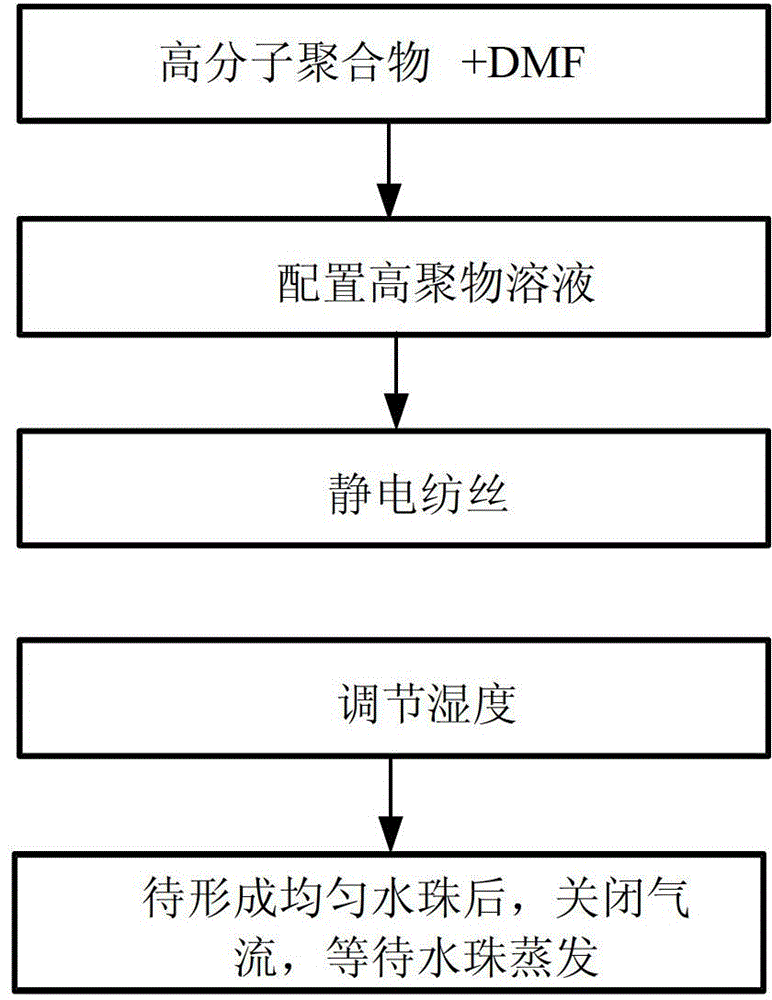

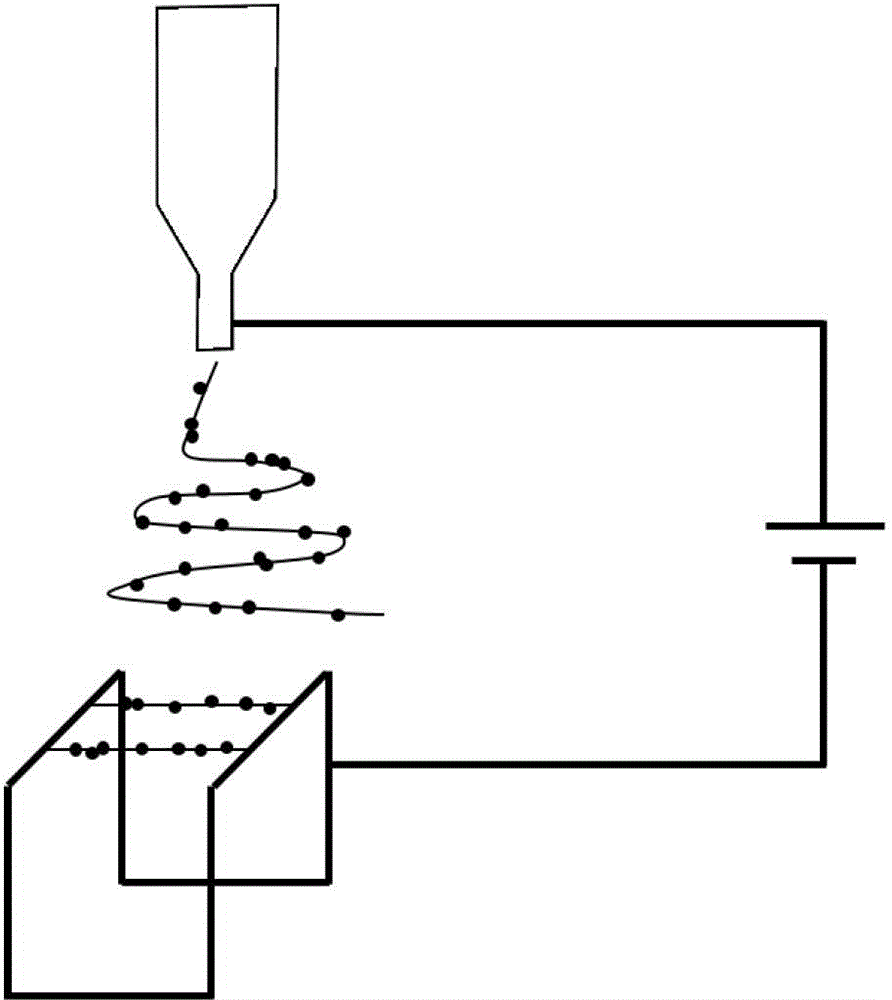

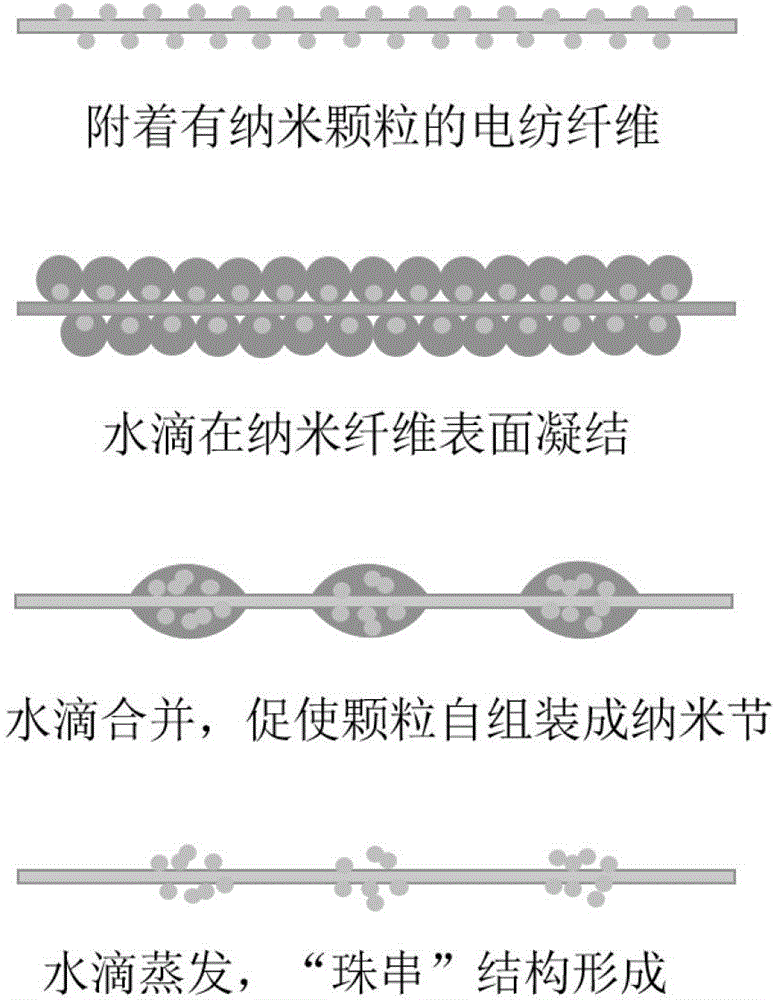

[0024] The invention provides a self-assembly preparation method of electrospun bead string fibers, such as figure 1 and figure 2 As shown, it is prepared by the following method:

[0025] The first step, the preparation of electrospinning raw materials:

[0026] Take N,N-dimethylformamide (DMF) with a purity of more than 99% and polyvinylidene fluoride (PVDF) with a purity of more than 99%, and mix the two evenly with a PVDF mass fraction of 17%. Stirred in a water bath at 35°C for 24h, a colorless and transparent viscous liquid mixture was obtained.

[0027] The second step, the preparation of man-made fibers:

[0028] Place the aluminum receiving bracket in the electrospinning device, draw an appropriate amount of the mixture obtained in the first step with a syringe, place it on the syringe pump, and electrospin it at a flow rate of 5mL / h at a DC voltage of 12kV, and the obtained product is made of aluminum Stent reception, during spinning, the needle is above the sup...

Embodiment 2

[0036] This example provides the preparation of a bead string fiber with self-assembly ability, and the specific implementation method includes the following steps:

[0037] The first step, the preparation of electrospinning raw materials:

[0038] Take N,N-dimethylformamide (DMF) with a purity of more than 99% and polyvinylidene fluoride (PVDF) with a purity of more than 99%, and mix the two evenly with a mass fraction of PVDF of 5% , and stirred for 24 h under water bath conditions at 35°C to obtain a colorless and transparent viscous liquid mixture.

[0039] The second step, the preparation of man-made fibers:

[0040] Place the aluminum receiving bracket in the electrospinning device, draw the mixture obtained in the first step with a syringe and place it on the syringe pump, and electrospin it at a flow rate of 10mL / h at a DC voltage of 20kV, and the obtained product is made of an aluminum receiving bracket. Support receiving, during spinning, the needle is above the al...

Embodiment 3

[0045] The first step, the preparation of electrospinning raw materials:

[0046] Take N,N-dimethylformamide (DMF) with a purity of more than 99% and polyvinylidene fluoride (PVDF) with a purity of more than 99%, and mix them uniformly with a mass fraction of PVDF of 7% at 35°C After stirring in a water bath for 96 hours, a colorless and transparent viscous liquid mixture was obtained.

[0047] The second step, the preparation of man-made fibers:

[0048] Place the aluminum receiving bracket in the electrospinning device, draw an appropriate amount of the mixture obtained in the first step with a syringe, place it on the syringe pump, and electrospin at a flow rate of 1mL / h at a DC voltage of 18kV, and the obtained product is made of aluminum Stent reception, during spinning, the needle is above the support at 18mm s -1 Move horizontally, after about 10s, take out the bracket.

[0049] The third step, the preparation of self-assembled "bead string" fibers:

[0050] Place t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com