Emergent exhausting system for high-temperature smoke

A technology for emergency discharge and high temperature flue gas, applied in exhaust gas devices, combustion product treatment, combustion methods, etc., can solve problems such as corrosion, and achieve the effect of eliminating hot corrosion, reducing system energy consumption, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

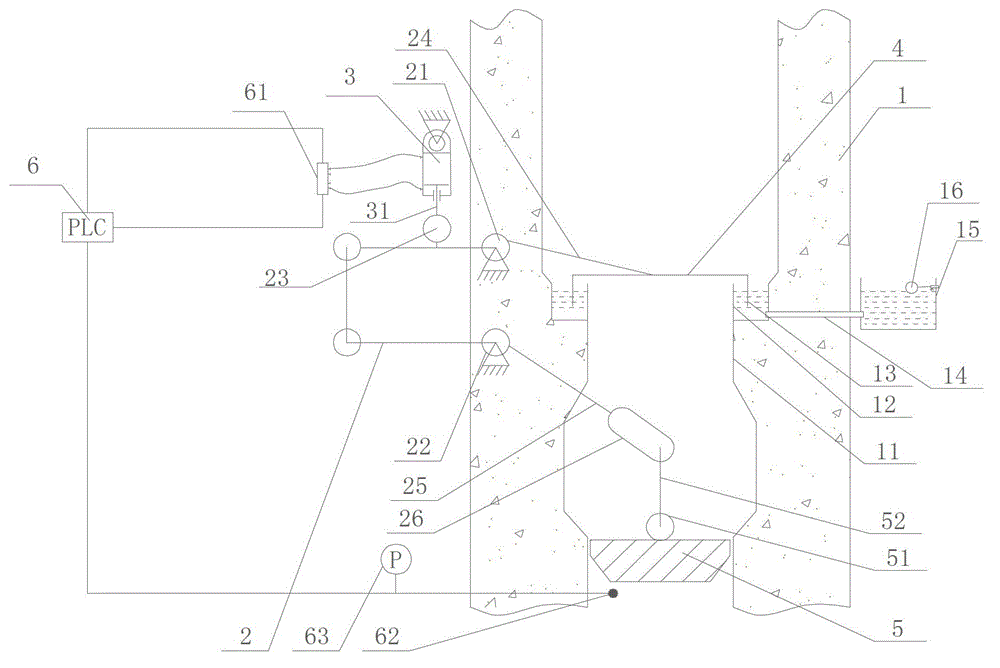

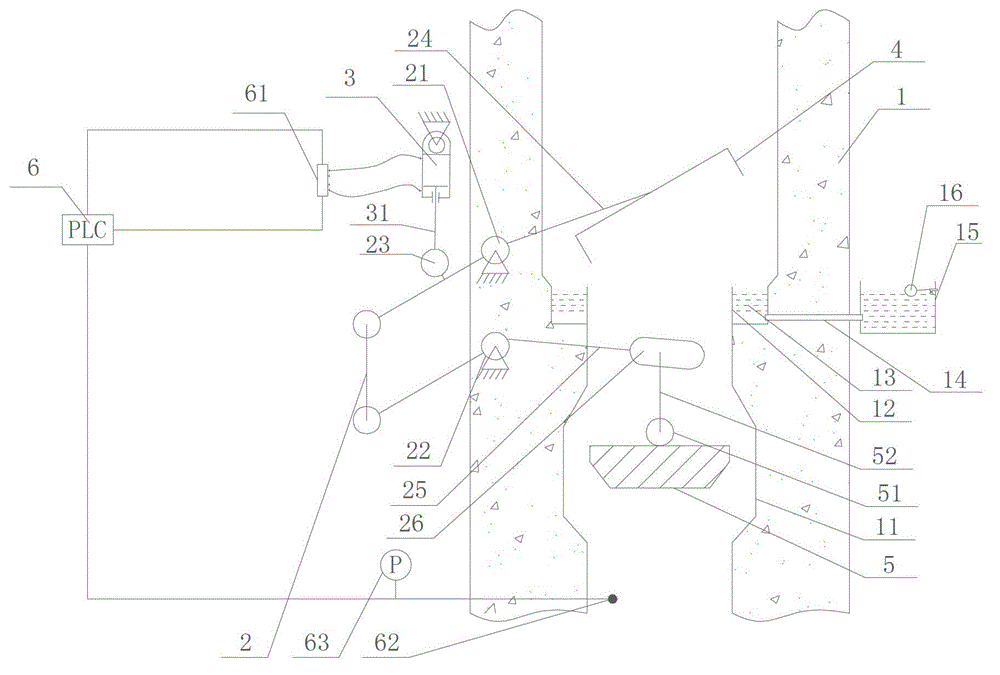

[0019] Attached below figure 1 , figure 2 Examples of the present invention will be described.

[0020] Such as figure 1 As shown, a high-temperature flue gas emergency exhaust system of the present invention includes a special-shaped flue 1 for discharging flue gas. The special-shaped flue 1 has a narrow throat portion 11, and also includes a parallel four-bar linkage mechanism 2 parallel to The four-bar linkage mechanism 2 includes four hinged shafts, two of which are fixed on the side walls of the special-shaped flue, and are shaped as an upper fixed hinged shaft 21 and a lower fixed hinged shaft 22; the upper parallel bar of the parallel four-bar linkage mechanism passes through a The hinge shaft 23 is connected to the piston rod of a cylinder 3; wherein, the throat part 11 of the special-shaped flue 1 is provided with a sealing door 4, and the lower part of the throat part 11 is provided with an insulating door 5; the sealing door 4 passes through an upper connecting f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com