Stable heat-collection control method for light field of trough type light-focusing solar thermal power plant

A control method and solar heat technology, applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of the flow delay of the heat transfer oil branch, speed up the replacement cycle of the heat transfer oil, and the temperature of the heat transfer oil overheating. Simple, solve the effect of stable light field collector control and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

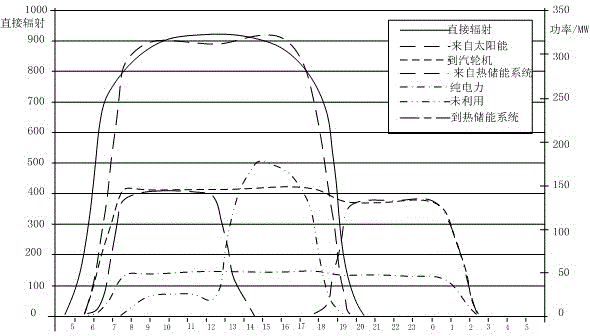

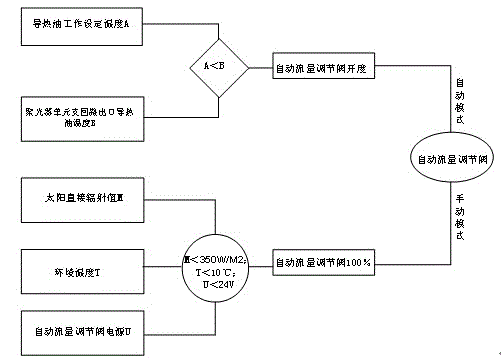

[0032] The installed capacity of trough concentrating solar thermal power stations generally exceeds 50MW, the light field scale reaches about 150 concentrator circuits, and there are huge heat transfer oil pipelines exceeding 2 square kilometers. At present, for the sake of economy, the trough-type concentrating solar thermal power station is equipped with only one heat transfer oil main pump located in the heat transfer oil main pipeline, which is responsible for circulating the heat transfer oil. Therefore, when adjusting the heat transfer oil main pump, the flow rate of the heat transfer oil branch where each concentrator circuit is located will have a significant lag.

[0033] When the direct radiation changes suddenly (such as cloudy days, the sun frequently enters and exits the clouds), the temperature of the heat transfer oil in the concentrator branch will also change sharply. If it is detected that the temperature of the heat transfer oil at the outlet of the If the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com