HCN (hydrogen cyanide) electrochemical sensor

A sensor and electrochemical technology, applied in the field of HCN four-electrode electrochemical sensor, to achieve accurate measurement and eliminate cross-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

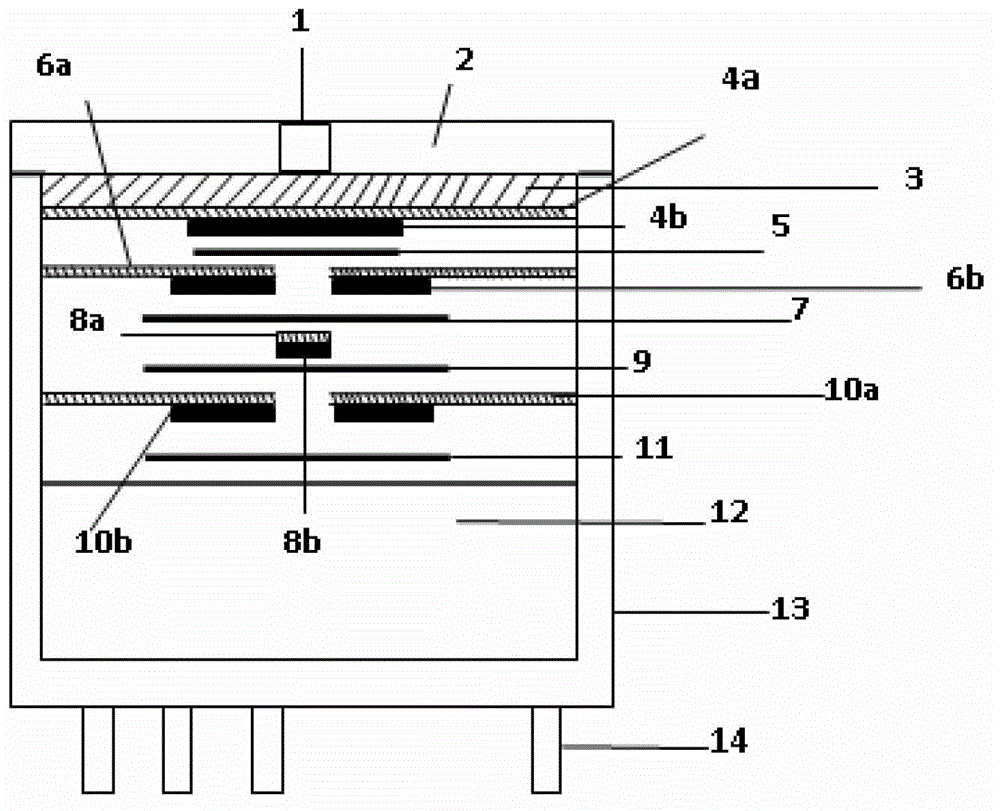

[0066] In this embodiment, the first working electrode of the HCN electrochemical sensor is a graphite electrode, and the second working electrode is an Au / C / graphite electrode, wherein the mass percentage of Au, C, and graphite is 4:3:3, and the counter electrode is Pt electrode, the reference electrode is a Pt electrode. Electrolyte is H 2 SO 4 Aqueous solution, the concentration is 6M. The electrochemically active materials of the counter electrode and the reference electrode are fixed on the PTFE waterproof and gas-permeable membrane.

[0067] The preparation process of the Au / C / graphite diffusion electrode in this example is basically the same as the preparation method of the Au / C electrode described in U.S. Patent 4,042,464, the difference is that a certain amount of graphite, graphite It is a good conductive material. On the one hand, it can increase the conductivity of the electrode, and on the other hand, it can reduce the cost. In addition, from a certain point of...

Embodiment 2

[0070] In this embodiment, the first working electrode of the HCN electrochemical sensor is a C electrode, the second working electrode is an Au / C electrode, wherein the mass percentage of Au and C is 3:2, the counter electrode is a Pt electrode, and the reference electrode for the Pt electrode. Electrolyte is H 2 SO 4 Aqueous solution, the concentration is 6M. The electrochemically active materials of the counter electrode and the reference electrode are fixed on the PTFE waterproof and gas-permeable membrane.

[0071] In this embodiment, the preparation process of the Au / C electrode is the same as that described in US Patent 4,042,464.

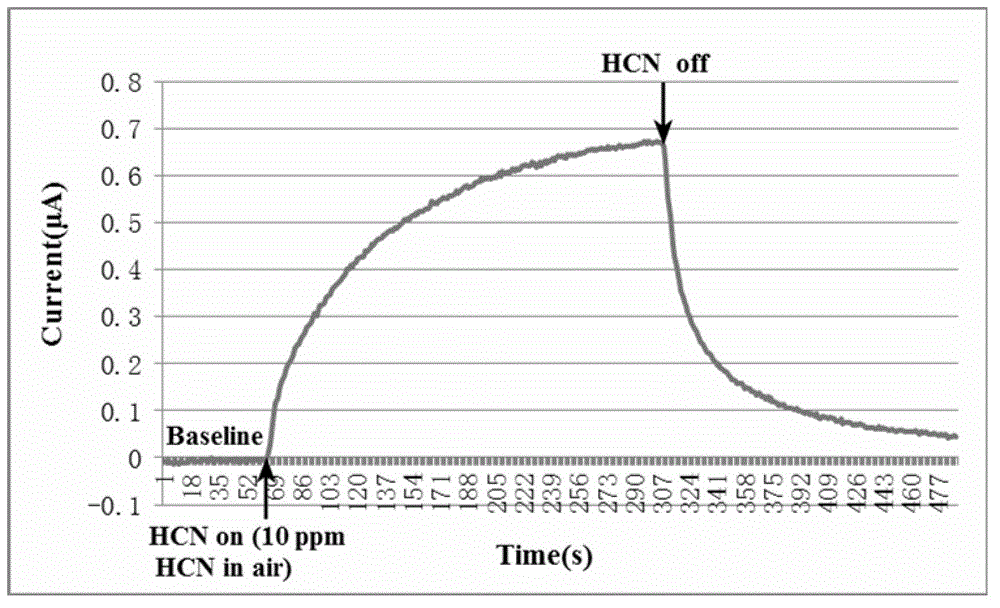

[0072] In the presence of NO and NO 2 To test the HCN gas in the case of interference, first the mixed gas of the three gases reaches the first working electrode (C electrode), and the first working electrode is at a potential of 1.35V relative to the standard hydrogen electrode. At this time, NO 2 Under the catalytic action of C catal...

Embodiment 3

[0077] In this embodiment, the first working electrode of the HCN electrochemical sensor is a graphite electrode, and the second working electrode is an Au / C / graphite electrode, wherein the mass percentages of Au, C, and graphite are 3.5:3:3.5, and the counter electrode is Pt electrode, the reference electrode is a Pt electrode. Electrolyte is H 2 SO 4 Aqueous solution, the concentration is 6M. The electrochemically active materials of the counter electrode and the reference electrode are fixed on the PTFE waterproof and gas-permeable membrane.

[0078] The preparation process of the Au / C / graphite diffusion electrode in this example is basically the same as the preparation method of the Au / C electrode described in U.S. Patent 4,042,464, the difference is that a certain amount of graphite, graphite It is a good conductive material. On the one hand, it can increase the conductivity of the electrode, and on the other hand, it can reduce the cost. In addition, from a certain po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com