Cooling device and method with function of noise reduction

A technology of a cooling device and a cooling method, which is applied in the field of computers, household appliances or electrical equipment, can solve the problems of increasing system energy consumption and low heat dissipation efficiency, and achieve the effects of improving cooling efficiency, improving heat dissipation efficiency, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment is a cooling method for reducing noise. The method uses magnetic / non-magnetic fluid as the heat dissipation medium, and the component to be cooled and the heat dissipation medium transfer heat to the magnetic / non-magnetic fluid through heat exchange. The magnetic / non-magnetic fluid is composed of Curie The temperature effect conducts heat through heat exchange. The magnetic fluid is composed of particles with permanent magnetism dispersed in the fluid; the non-magnetic fluid is composed of particles with magnetic properties dispersed in the fluid. That is to say, this embodiment includes two technical solutions. When the component to be cooled is non-magnetic, the magnetic fluid is used as the heat dissipation medium. The component to be cooled and the heat dissipation medium transfer heat to the magnetic fluid through heat exchange, and the magnetic fluid passes heat through the Curie temperature effect. After the exchange, the heat is transferred out to...

Embodiment 2

[0031] This embodiment is the application of the cooling method of the present invention in cooling the microwave oven magnetron, that is, a method for reducing the noise of the microwave oven. Since the magnetron is not magnetic during operation, the method uses a magnetic fluid cooling system instead of air cooling ( oil cooling) system to dissipate heat from the magnetron in the microwave oven. The magnetic fluid cooling system covers the magnetron with a fluid channel with thermal conductivity, and the heat of the magnetron is conducted from the magnetic fluid in the fluid channel after convective circulation . In this embodiment, the Curie temperature of the magnetic powder is lower than the heat-resistant temperature of the magnetron, and the magnetic fluid is composed of particles with permanent magnetism dispersed in the fluid.

Embodiment 3

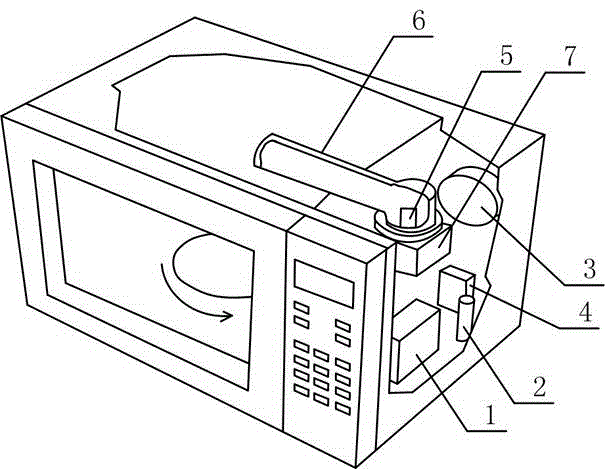

[0033] This embodiment is the application of cooling device of the present invention in cooling microwave oven magnetron, see figure 1 As shown, the cooling fan in the prior art microwave oven is mainly designed for the cooling of the magnetron. Traditionally, forced air cooling (see figure 1 structure).

[0034] In order to avoid the disadvantages of high mechanical noise and low heat dissipation efficiency generated by the fan during operation, the following solutions are proposed.

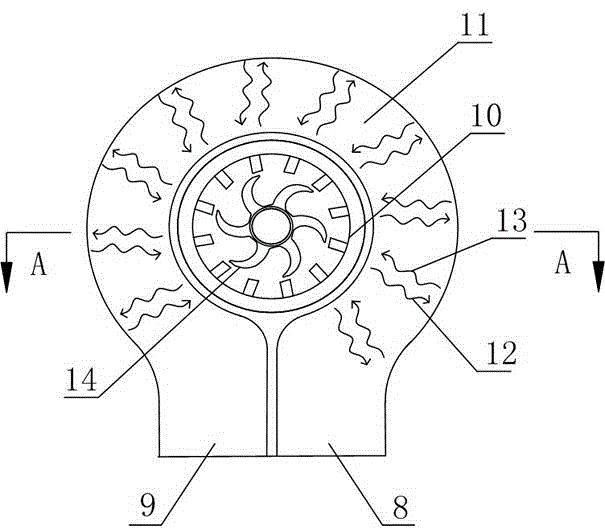

[0035] Such as figure 2 , image 3 As shown, the scheme cancels the fan, and surrounds the magnetron 10 with a fluid channel 11 with better thermal conductivity. Since the magnetron 10 is not magnetic, a magnetic fluid is provided in the fluid channel 11. The magnetic fluid is composed of particles with permanent magnetism dispersed in the fluid. The heat of the magnetron 10 can be effectively and quickly conducted out through the magnetic fluid in the fluid channel 11, with high heat dissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com