pH sensor integration to single use bioreactor/mixer

A bioreactor container, bioreaction technology, applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biochemical instruments, etc., can solve problems such as affecting the service life of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

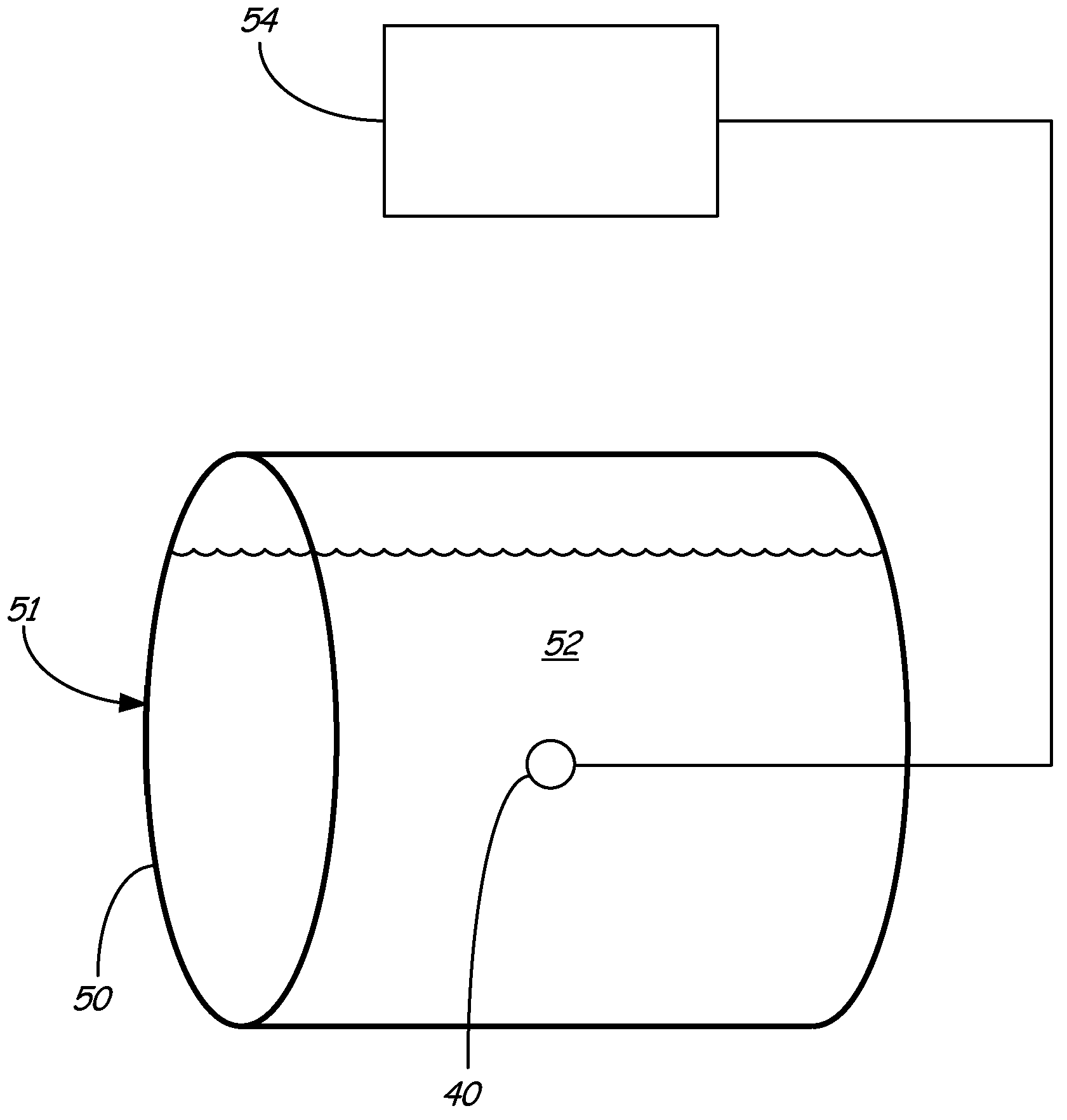

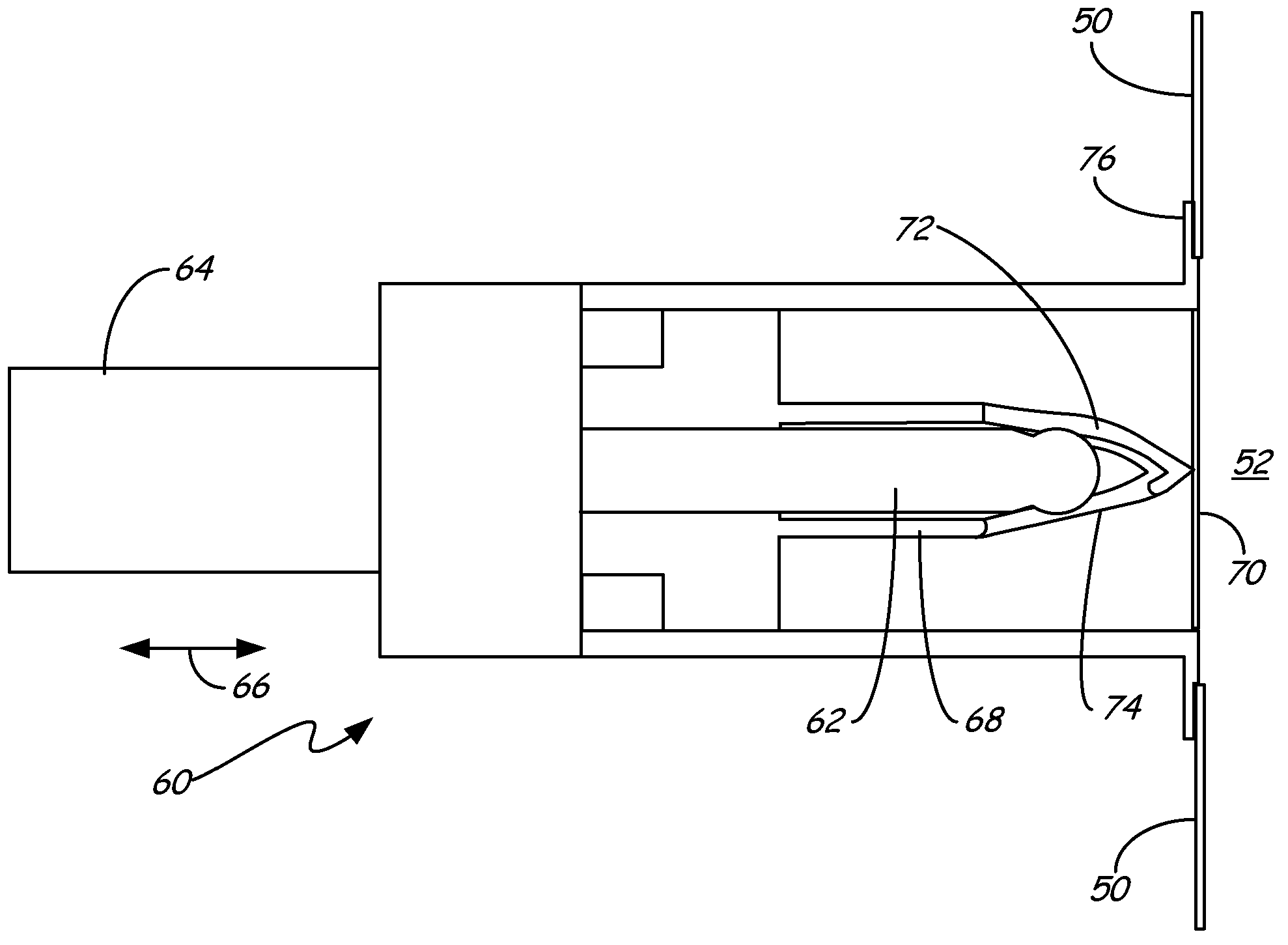

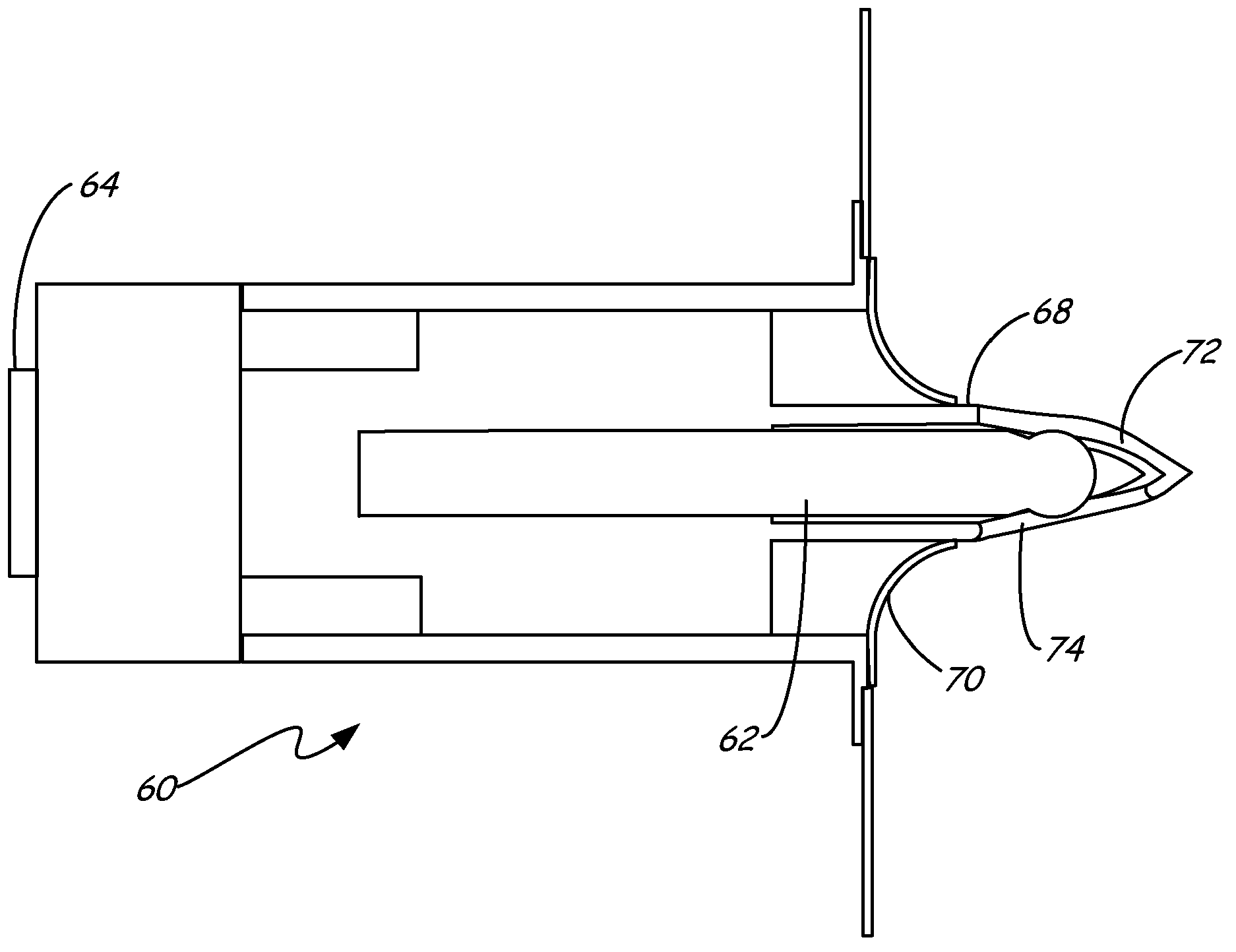

[0018] It is believed that there is a need for a disposable pH sensor compatible with plastic bag type, ready to use, disposable bioreactors. Many pH sensors based on glass electrodes require protection of the sensor's reactive surface or membrane from physical or environmental damage. This function is usually provided by a disposable "shield" or cap that covers the sensing end of the sensor.

[0019] Embodiments of the present invention generally include a pH sensor mounted to the wall of a single-purpose bioreactor / mixer, wherein the bioreactor / mixer has a bacteria (gamma ray irradiation), mechanical structures that allow protective solutions to be stored around the pH sensing and reference elements during storage and transport. The mechanism also allows the storage cavity holding the protective solution to be opened to expose the detection and reference elements prior to manipulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com