Machining device and machining method of metal foils

A metal foil and processing device technology, which is applied in metal processing and other directions, can solve the problems of insufficient precision and low efficiency, and achieve the effects of facilitating the recycling of finished products, improving cutting speed and precision, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

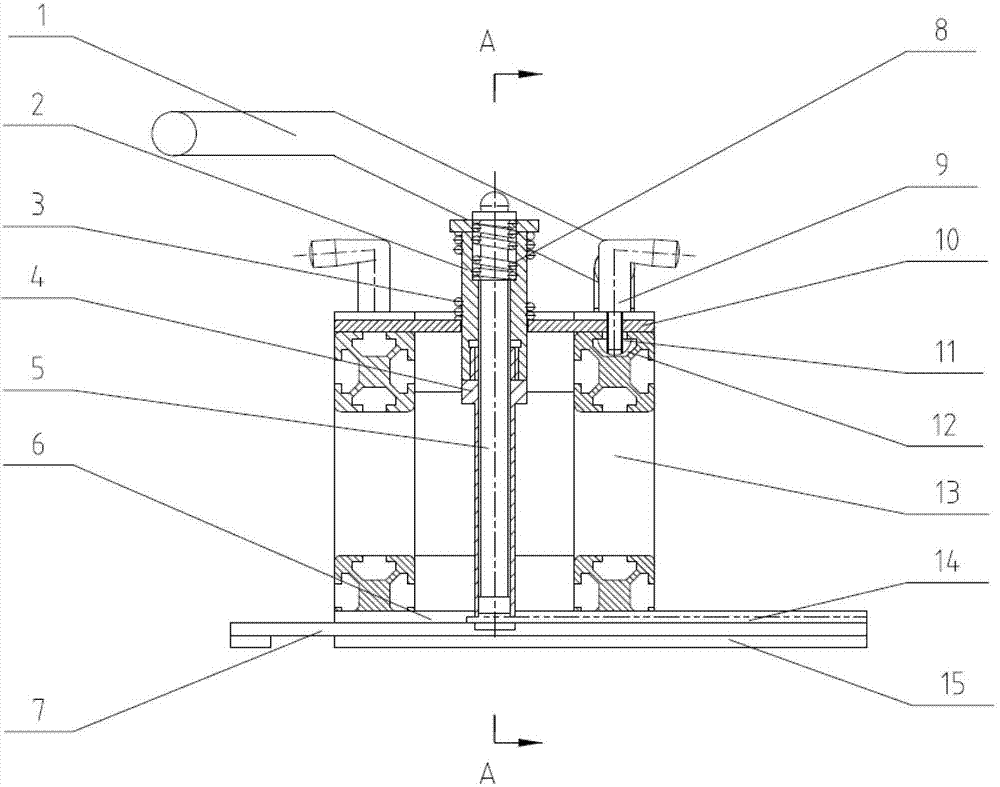

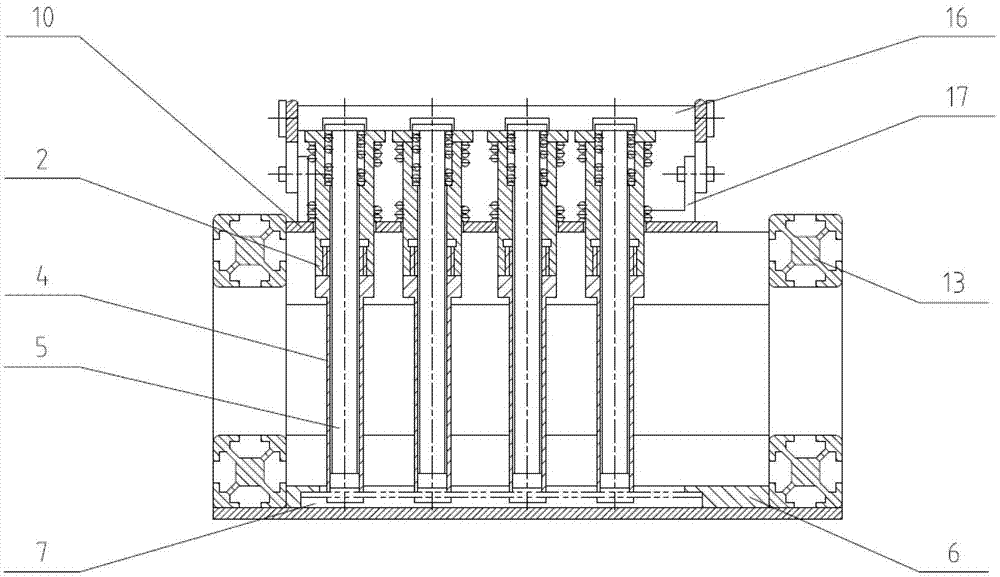

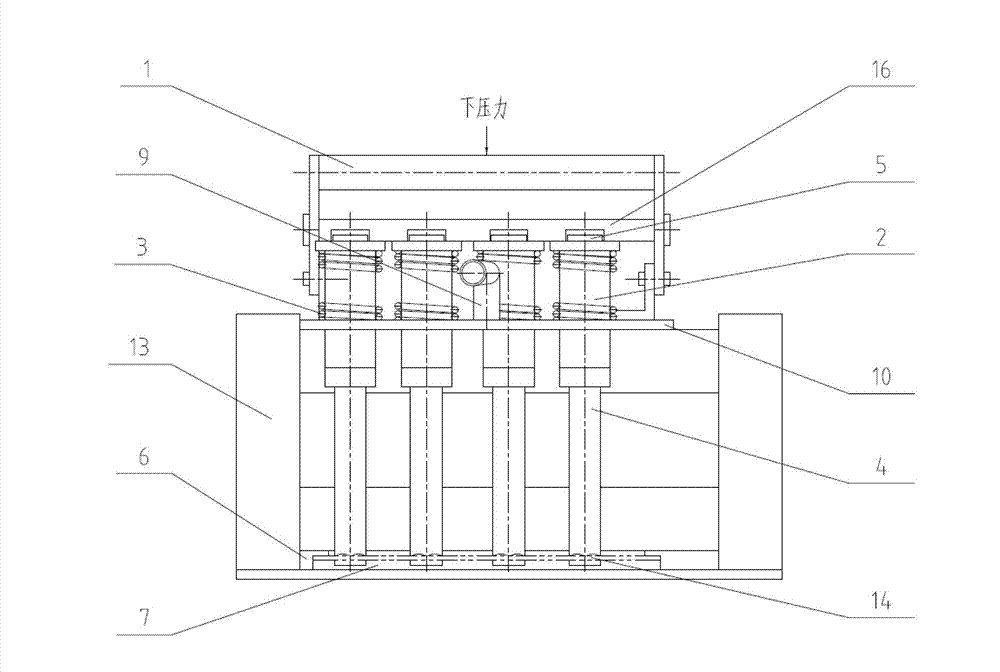

[0014] Such as figure 1 , figure 2 As shown, the processing device of the present invention is mainly composed of handle 1, support rod 2, support spring 3, cutter head 4, internal pressure head 5, binder plate 6, bottom mold 7, pressure head spring 8, locking handle 9, support Plate 10, slide block 11, groove 12, main frame 13, base plate 15, pressure bar 16, handle bracket 17 constitute. The handle 1, the support rod 2, the locking handle 9, and the handle bracket 17 are all installed on the support plate 10, the support spring 3 and the inner pressure head spring 8 are respectively set on the support rod 2 and the inner pressure head 5, and the cutter head 4 is connected with the support plate The rod 2 is threaded, the inner pressure head 5 is installed at the center of the support rod 2, the binder plate 6 is connected with the bottom mold 7 and installed on the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com