High-transmittance optical brightness enhancement film, and manufacture apparatus and manufacture process thereof

A high transmittance, manufacturing equipment technology, applied in prisms and other directions, can solve the problems of complex manufacturing process and low transmittance, and achieve the effects of stable refractive index, improved transmittance, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

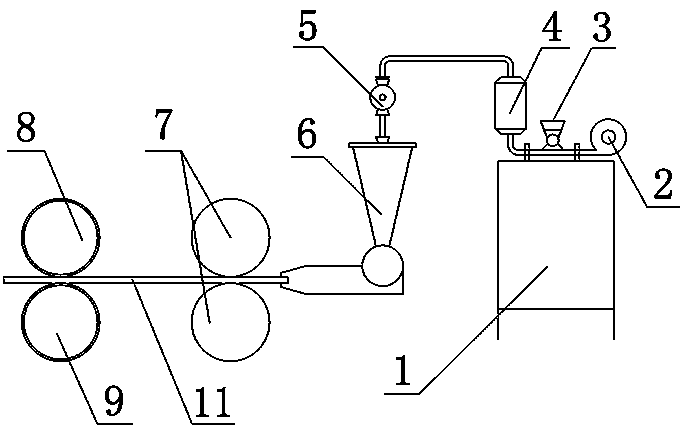

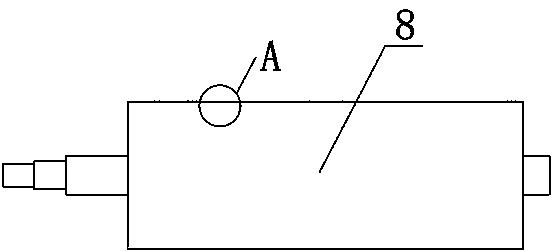

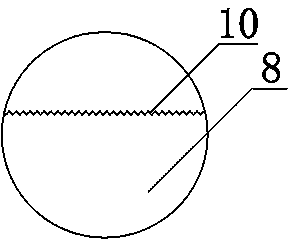

[0034] Such as figure 1 , figure 2 and image 3 As shown, a high transmittance optical brightening film manufacturing equipment, which includes a hot air blower 2, a feed hopper 3, a hot air dryer 4, an air locker 5, hot-melt equipment 6, a patterned roller 8 and a frosted roller 9. The hot air blower 2 is fixedly installed on one side of the platform 1, and the hot air dryer 4 is installed on the other side of the platform 1. The pipeline connecting the hot air blower 2 and the hot air dryer 4 is provided with a feed hopper 3, and the hot air dryer 4 The outlet end of the air locker 5 is connected to the inlet end of the air locker 5, and the outlet end of the air locker 5 is connected to the inlet end of the hot-melt equipment 6. The outlet end of the hot-melt equipment 6 is provided with a calendering smooth roller group 7, and the patterned roller 8 is connected with the frosted The roll 9 is matched and arranged on the left side of the calender roll group 7 .

[0035]...

Embodiment 2

[0049] A high-transmittance optical brightness-enhancing film manufacturing equipment, the structure of which is the same as that of Embodiment 1.

[0050] A process for manufacturing an optical brightness-enhancing film using the manufacturing equipment of the optical brightness-enhancing film of high transmittance, which includes the following steps:

[0051] S1. Preparation of patterned roll: electroplate a nickel alloy layer with a thickness of 750 μm on the surface of the calendered smooth roll by electrochemical method, use an ultra-precision diamond special machine tool, and the ambient temperature is 20 ° C, engrave the tooth shape on the nickel alloy layer Grating structure with a pitch of 150 μm;

[0052] S2, material preparation: select PC, PMMA or PET with a transmittance of 88% and a refractive index of 1.57 as the base material, and fully mix it with a plasticizer and a light diffusing agent in a ratio of 100:1.5:1.5, and set aside;

[0053] S3, drying: the mixtur...

Embodiment 3

[0061] A high-transmittance optical brightness-enhancing film manufacturing equipment, the structure of which is the same as that of Embodiment 1.

[0062] A process for manufacturing an optical brightness-enhancing film using the manufacturing equipment of the optical brightness-enhancing film of high transmittance, which includes the following steps:

[0063] S1. Preparation of patterned roll: electroplate a nickel alloy layer with a thickness of 1000 μm on the surface of the calendered smooth roll by electrochemical method, use an ultra-precision diamond special machine tool, and the ambient temperature is 20.1 ° C, engrave teeth on the nickel alloy layer Grating structure with a pitch of 250 μm;

[0064] S2, material preparation: select PC, PMMA or PET with a transmittance of 90% and a refractive index of 1.53 as the base material, and fully mix it with a plasticizer and a light diffusing agent in a ratio of 100: 2: 2, and set aside;

[0065] S3, drying: the mixture obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com