Method for preparing YAG-Ce fluorescent powder for white-light LED (light-emitting diode)

A fluorescent powder and white light technology, applied in the field of fluorescent powder, can solve the problems of non-environmental protection and energy consumption, and achieve the effects of reduced manufacturing costs, lower reaction temperatures, and lower energy costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

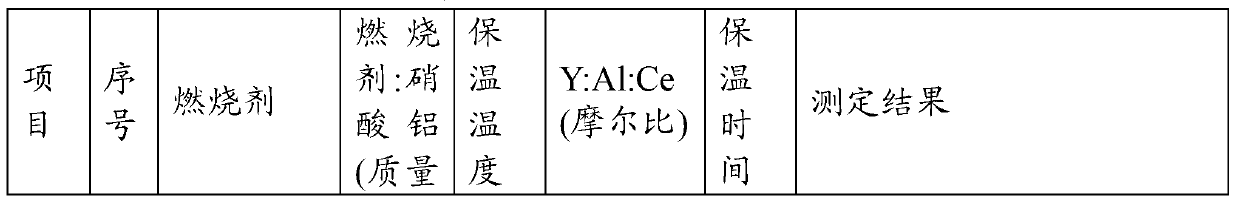

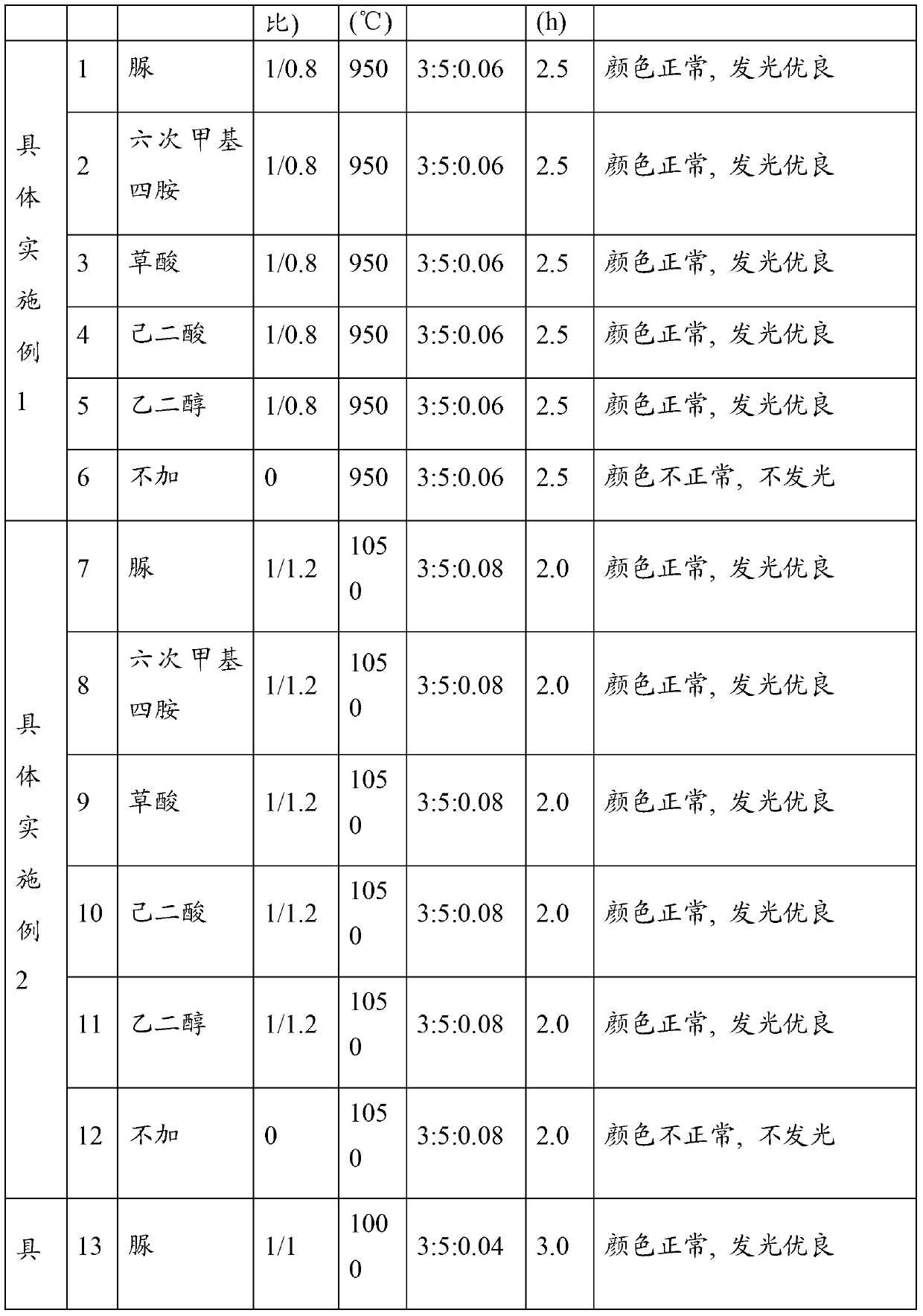

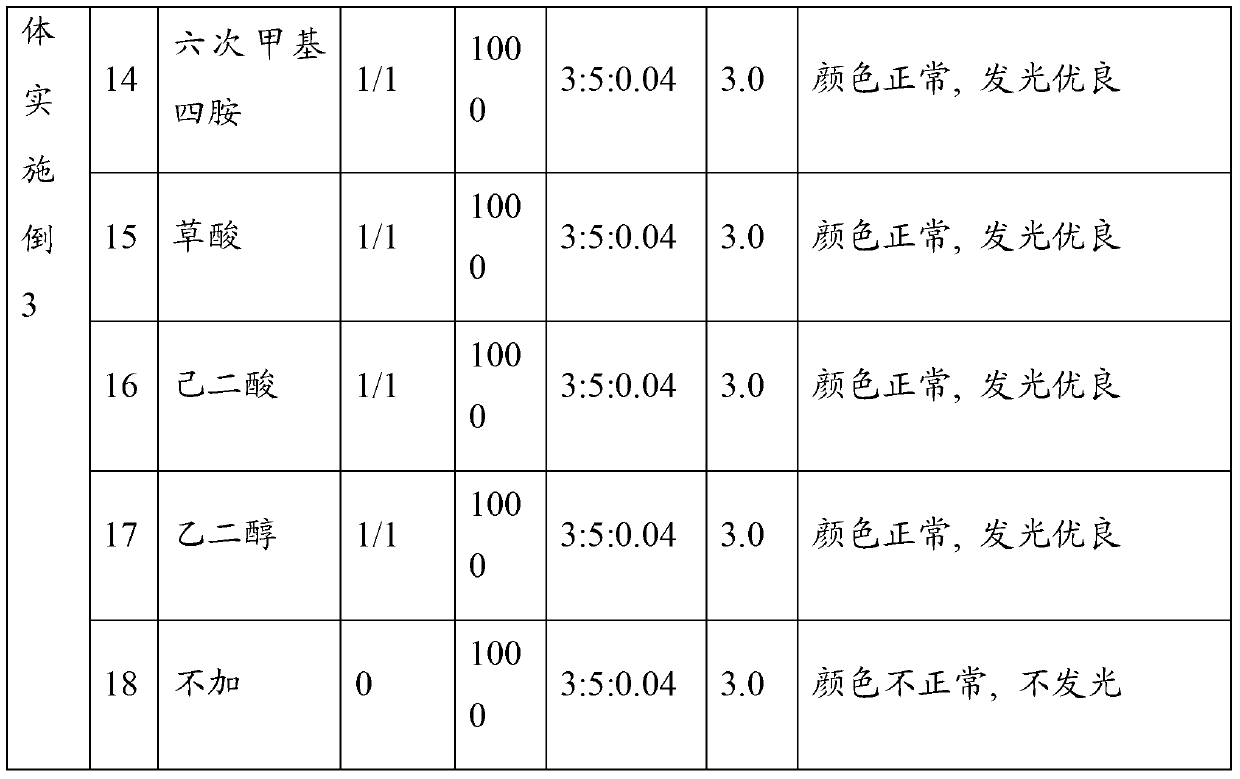

[0020] First weigh the burning agent urea and the raw materials for preparing YAG-Ce phosphor: including aluminum nitrate, cerium nitrate, and yttrium oxide; the weight ratio of urea / aluminum nitrate is 1 / 0.8, and the amount of aluminum nitrate, cerium nitrate, and yttrium oxide is controlled by molar ratio: Y:Al:Ce=3:5:0.06.

[0021] In the manufacturing process, including: mixing, rubbing, heating and heating, burning, heat preservation, cooling and other processes. Firstly weigh the reaction raw materials according to the ratio of the above raw materials, mechanically mix and rub them evenly, start to heat up the temperature, and when it reaches 300-600°C, combustion phenomenon occurs, then raise the temperature to 950°C, keep the reaction at this temperature for 2.5 hours, and gradually cool down to room temperature, a yellow powder was obtained. Ball milling and passing through a 300-mesh sieve to obtain YAG-Ce phosphor.

[0022] Comparing the five groups using differen...

Embodiment 2

[0024] First weigh the burning agent urea and the raw materials for preparing YAG-Ce phosphor: including aluminum nitrate, cerium nitrate, and yttrium oxide; the weight ratio of urea / aluminum nitrate is 1 / 1.2, the amount of aluminum nitrate, cerium nitrate, and yttrium oxide is controlled by molar ratio: Y:Al:Ce=3:5:0.08.

[0025] In the manufacturing process, except that the heat preservation temperature is 1050° C., and the heat preservation reaction time is 2 hours, the method of embodiment 2 is the same as that of embodiment 1.

[0026] Comparing five groups of different organic combustion agents (respectively, hexamethylenetetramine, oxalic acid, adipic acid, ethylene glycol, without adding any combustion agent), the combustion synthesis of YAG-Ce phosphors was carried out, and the experiment See Table 1 for the data of numbers 7, 8, 9, 10, 11, and 12.

Embodiment 3

[0028] First weigh the burning agent urea and the raw materials for preparing YAG-Ce phosphor: including aluminum nitrate, cerium nitrate, and yttrium oxide; the weight ratio of urea / aluminum nitrate is 1 / 1, and the amount of aluminum nitrate, cerium nitrate, and yttrium oxide is controlled by molar ratio: Y:Al:Ce=3:5:0.04.

[0029] In the manufacturing process, except that the heat preservation temperature is 1000° C., and the heat preservation reaction time is 3 hours, the method of specific embodiment 3 is the same as that of specific embodiment 1.

[0030] Comparing five groups of different organic combustion agents (respectively, hexamethylenetetramine, oxalic acid, adipic acid, ethylene glycol, without adding any combustion agent), the combustion synthesis of YAG-Ce phosphors was carried out, and the experiment See Table 1 for the data of numbers 13, 14, 15, 16, 17, and 18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com