Method for improving coercive force of Sm5Co19 alloy through step-by-step doping

A coercive force and alloy technology, which is applied in the field of improving the coercive force of Sm-Co permanent magnet alloys, can solve problems such as the inability to effectively improve Sm, and achieve the improvement of coercivity, magnetocrystalline anisotropy, and coercivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

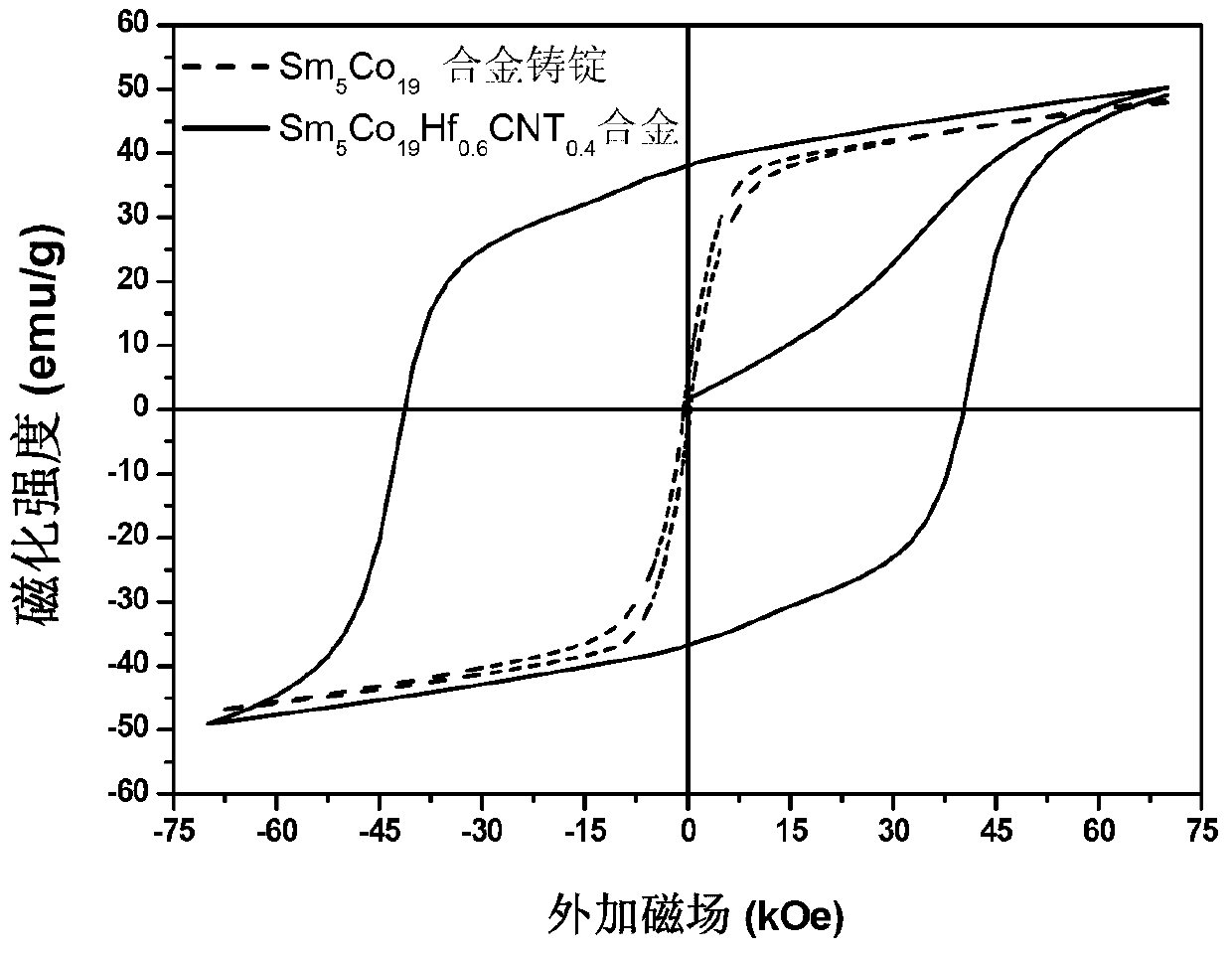

Embodiment 1

[0025] (1) Divide the composition into Sm 5 co 19 The alloy ingot is crushed into a powder below 100 microns, the crushed powder is mixed with the Hf powder according to the molar ratio of 1:0.6, and the mixed powder is put into a ball mill tank according to the mass ratio of ball to material of 45:1, and the ball mill time is 30 Hour;

[0026] (2) Under the protection of inert gas, mix the ball-milled powder obtained in step (1) with multi-walled carbon nanotubes (CNTs) evenly, according to Sm 5 co 19 The molar ratio with multi-walled carbon nanotubes (CNT) is 1:0.4;

[0027] (3) Put the mixed powder in step (2) into the mold, and use spark plasma sintering method for sintering. The process parameters are as follows: first, apply a pressure of 300MPa to the mixed powder in the mold, and then heat it after pressurization, with a heating rate of 50°C / min, after heating up to 550°C, immediately cooling to room temperature without heat preservation, to obtain Sm 5 co 19 f 0...

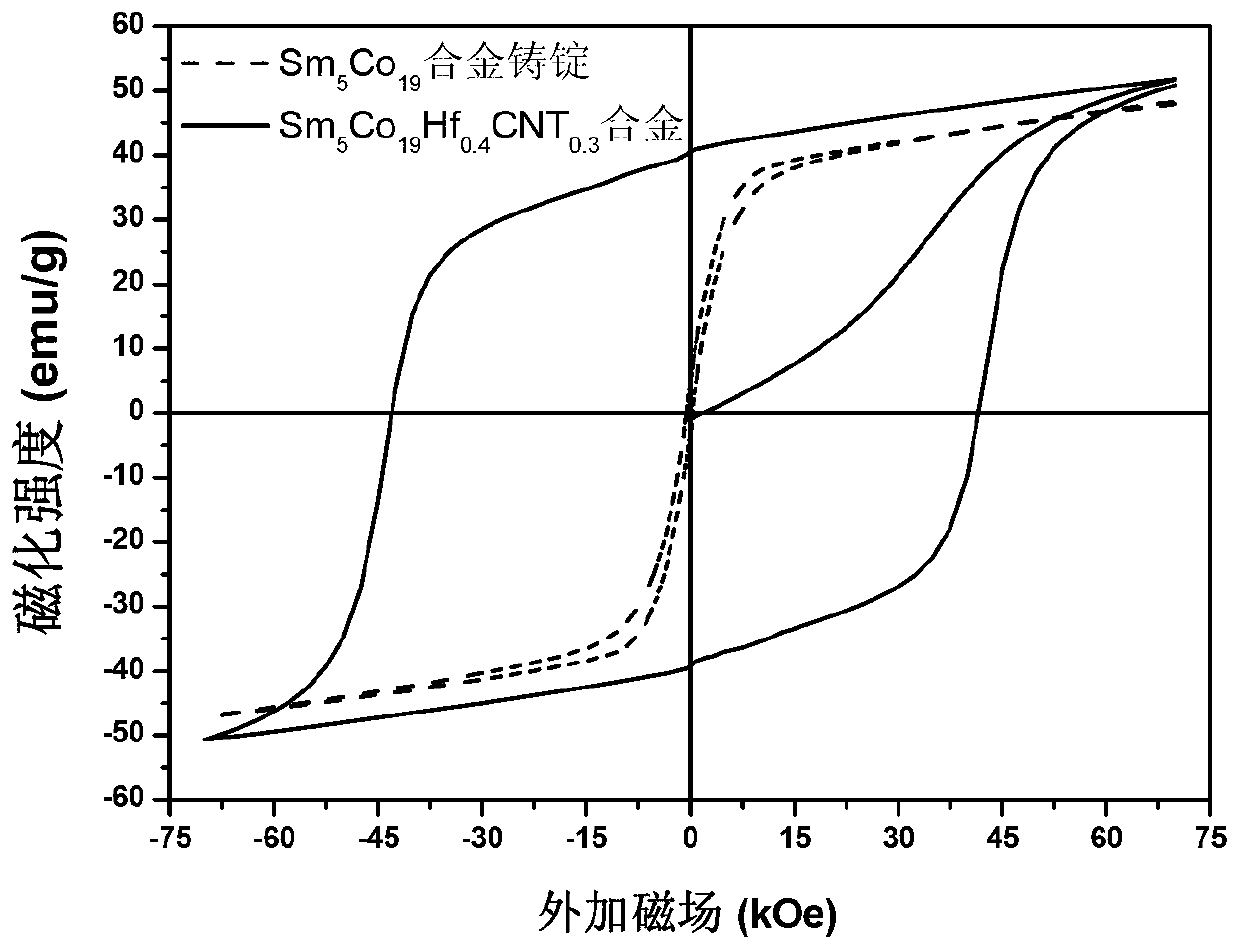

Embodiment 2

[0029] (1) Divide the composition into Sm 5 co 19 The alloy ingot is crushed into a powder below 75 microns, the crushed powder is mixed with the Hf powder according to the molar ratio of 1:0.4, and the mixed powder is put into a ball milling tank according to the mass ratio of ball to material of 50:1, and the ball milling time is 25 Hour;

[0030] (2) Under the protection of inert gas, mix the ball-milled powder obtained in step (1) with multi-walled carbon nanotubes (CNTs) evenly, according to Sm 5 co 19 The molar ratio with multi-walled carbon nanotubes (CNT) is 1:0.3;

[0031] (3) Put the mixed powder in step (2) into the mold, and use spark plasma sintering method for sintering. The process parameters are as follows: first, apply a pressure of 500MPa to the mixed powder in the mold, and then heat it after pressurization, with a heating rate of 100°C / min, after heating up to 450°C, immediately cool down to room temperature without keeping warm, and get Sm 5 co 19 f...

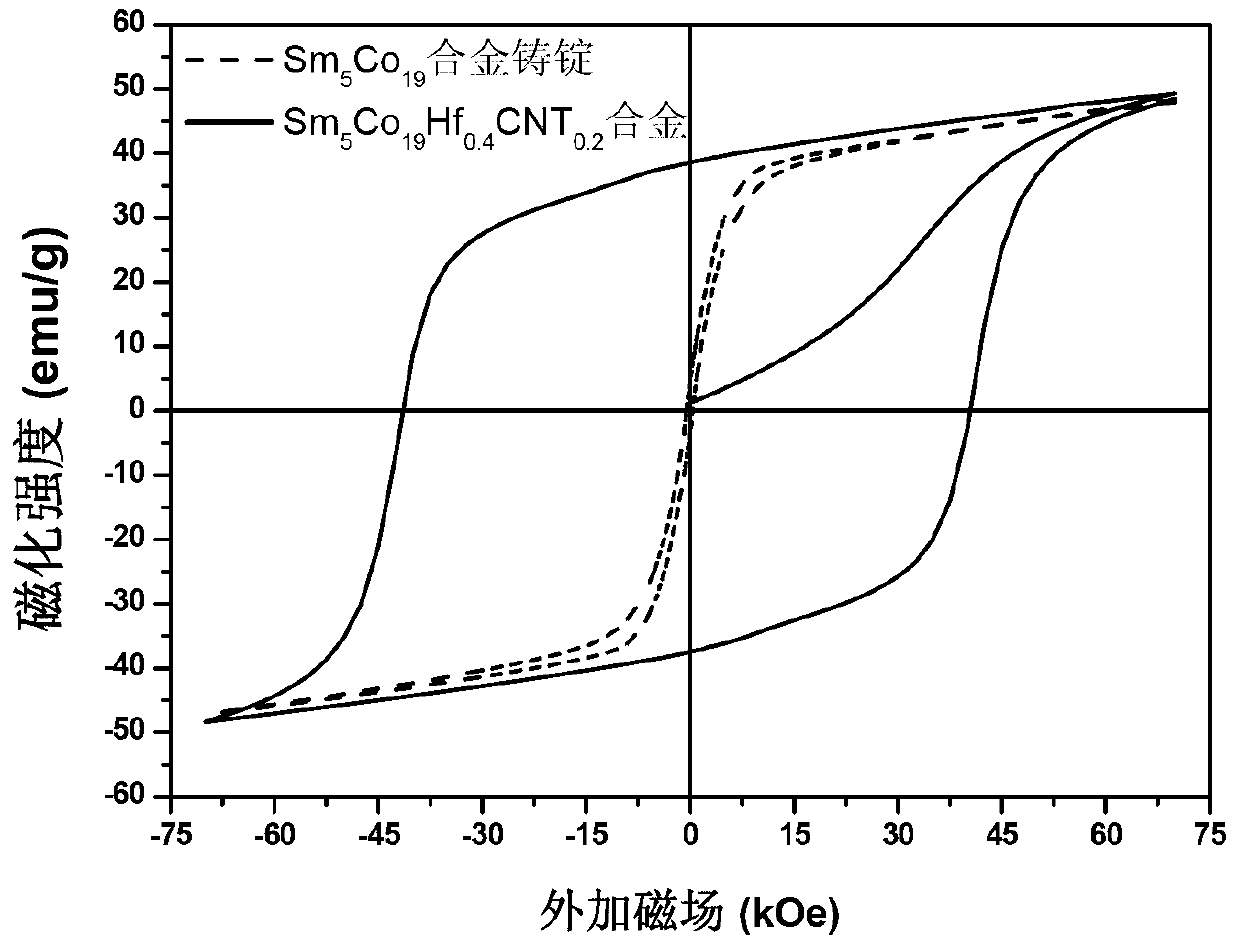

Embodiment 3

[0033] (1) Divide the composition into Sm 5 co 19 The alloy ingot is crushed into a powder below 90 microns, the crushed powder is mixed with the Hf powder according to the molar ratio of 1:0.4, and the mixed powder is put into a ball mill tank according to the mass ratio of ball to material of 40:1, and the ball mill time is 40 Hour;

[0034] (2) Under the protection of inert gas, mix the ball-milled powder obtained in step (1) with multi-walled carbon nanotubes (CNTs) evenly, according to Sm 5 co 19 The molar ratio with multi-walled carbon nanotubes (CNT) is 1:0.2;

[0035] (3) Put the mixed powder in step (2) into the mold, and use spark plasma sintering method for sintering. The process parameters are as follows: first, apply a pressure of 450MPa to the mixed powder in the mold, and then heat it after pressurization, and the heating rate is 80°C / min, after heating up to 400°C, immediately cooling to room temperature without keeping warm, and obtaining Sm 5 co 19 f ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com