Instant waste heat recycling heating unit and water outflow thermostatic control method thereof

A technology of waste heat recovery and constant temperature control, which is applied to machines, fluid heaters, lighting and heating equipment using waste heat, which can solve the problem that waste heat cannot be fully recycled, waste water cannot be stored for a long time, and waste hot water cannot be stored for a long time. Large emissions, etc., to achieve efficient operation, increase the suction temperature, and increase the effect of heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

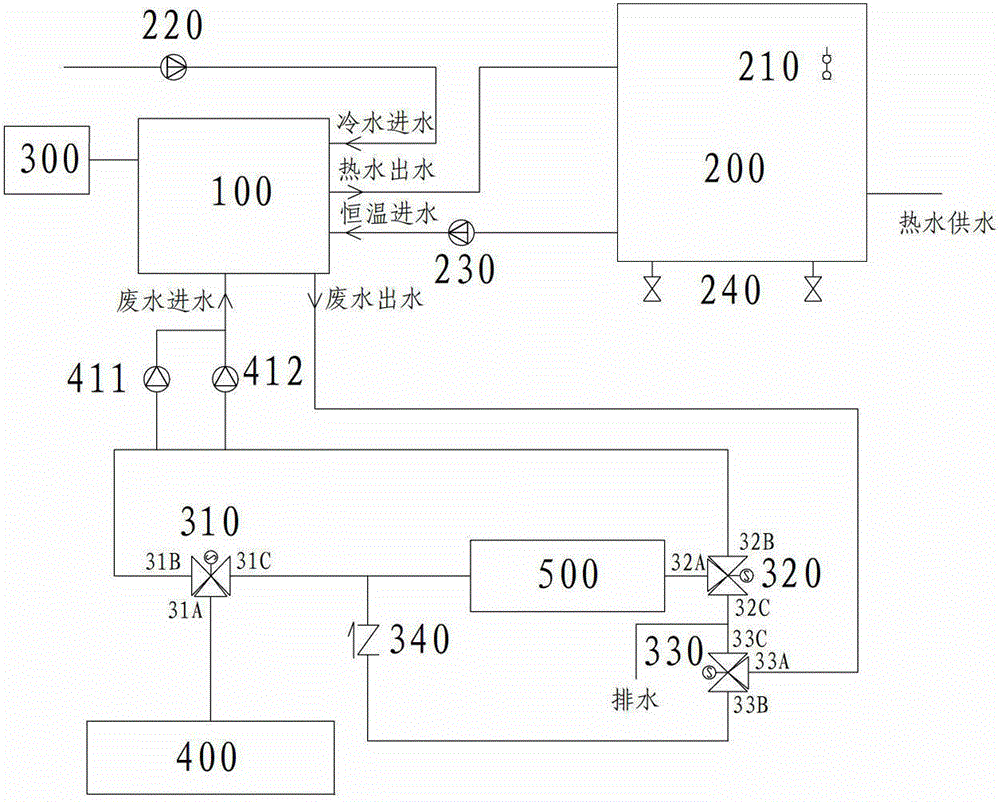

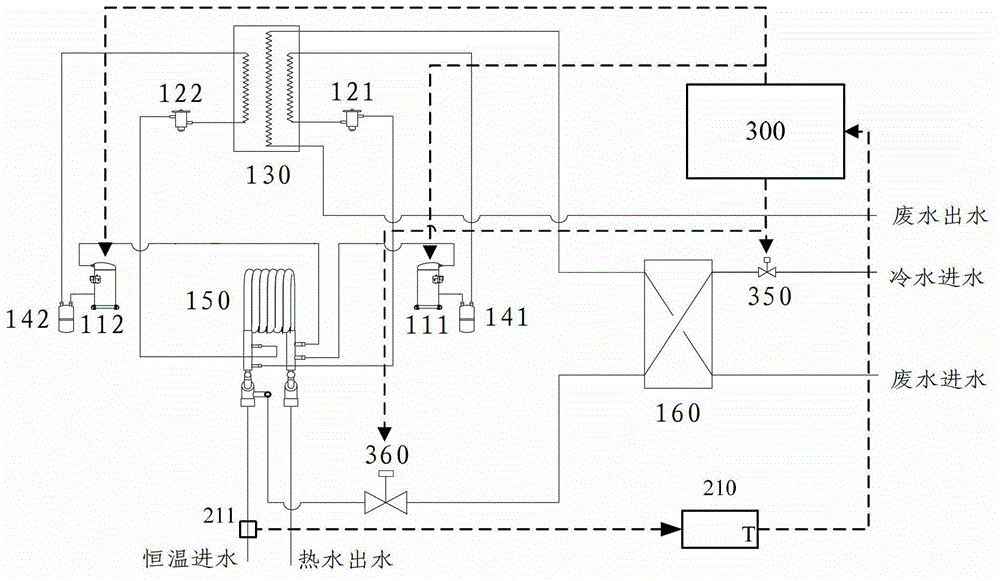

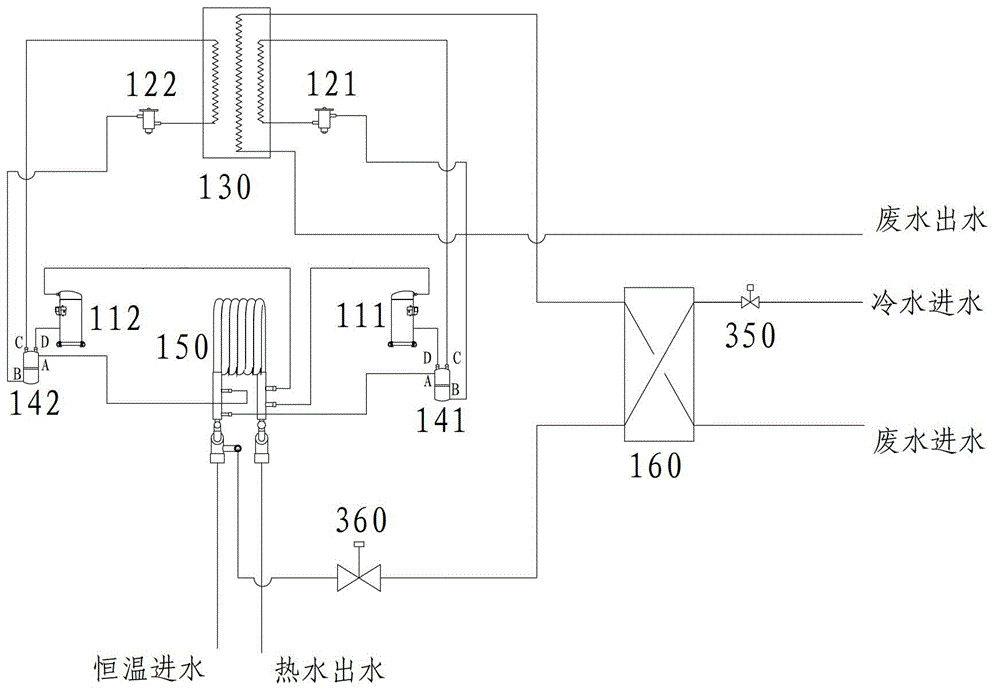

Embodiment 1

[0086] Cooling and hot water operation mode: after the waste water feeds at 50°C-70°C and the cold water feeds at 15°C and passes through the water / water heat exchanger 160 for primary heat recovery, the water temperature in the waste water tank drops to between 30°C-40°C, while the cold water The temperature rises to 25°C-30°C, then the waste water flows into the evaporator 130 for secondary heat recovery, the temperature of the heat recovered waste water drops to about 12°C, and the 12°C waste water from the evaporator 130 passes through the third three-way valve 330, through the one-way valve 340, it flows into the end 500 of the air conditioner for refrigeration. The cold water heated to 25°C-30°C passes through the thermostatic control valve 350 and then flows into the condenser 150 for secondary heating. The single-chip control unit 300 detects the water temperature of the hot water tank in real time, calculates the opening degree of the thermostatic control valve accord...

Embodiment 2

[0088] Working mode of heating and hot water production in winter: the waste hot water at 50°C-70°C from the waste water pool passes through the first three-way valve 310 and enters the air conditioner end 500 to realize the heating function, and the waste water flowing out of the air conditioner end 500 passes through the second The three-way valve 320, through the first heat source circulation pump 411 and / or the second heat source circulation pump 412, realizes the function of two-stage heat recovery to produce hot water; The water heat exchanger 160 performs primary heat exchange with the 5°C-10°C cold water from the water inlet solenoid valve 350, the water temperature of the waste water tank drops to 20°C-30°C, and the cold water temperature rises to 15°C-25°C. The waste water flowing out of the water / water heat exchanger 160 flows into the evaporator 130 for secondary heat recovery, the temperature of the waste water after the secondary heat recovery drops to about 8°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com