Multifunctional high-accuracy hardened concrete test-piece treatment machine

A concrete specimen, high-precision technology, applied in the preparation of test samples, sampling devices, etc., can solve the problems of reduced grinding efficiency, excessive grinding, and unstable rotation, so as to improve the degree of automation, extend the service life, and ensure reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

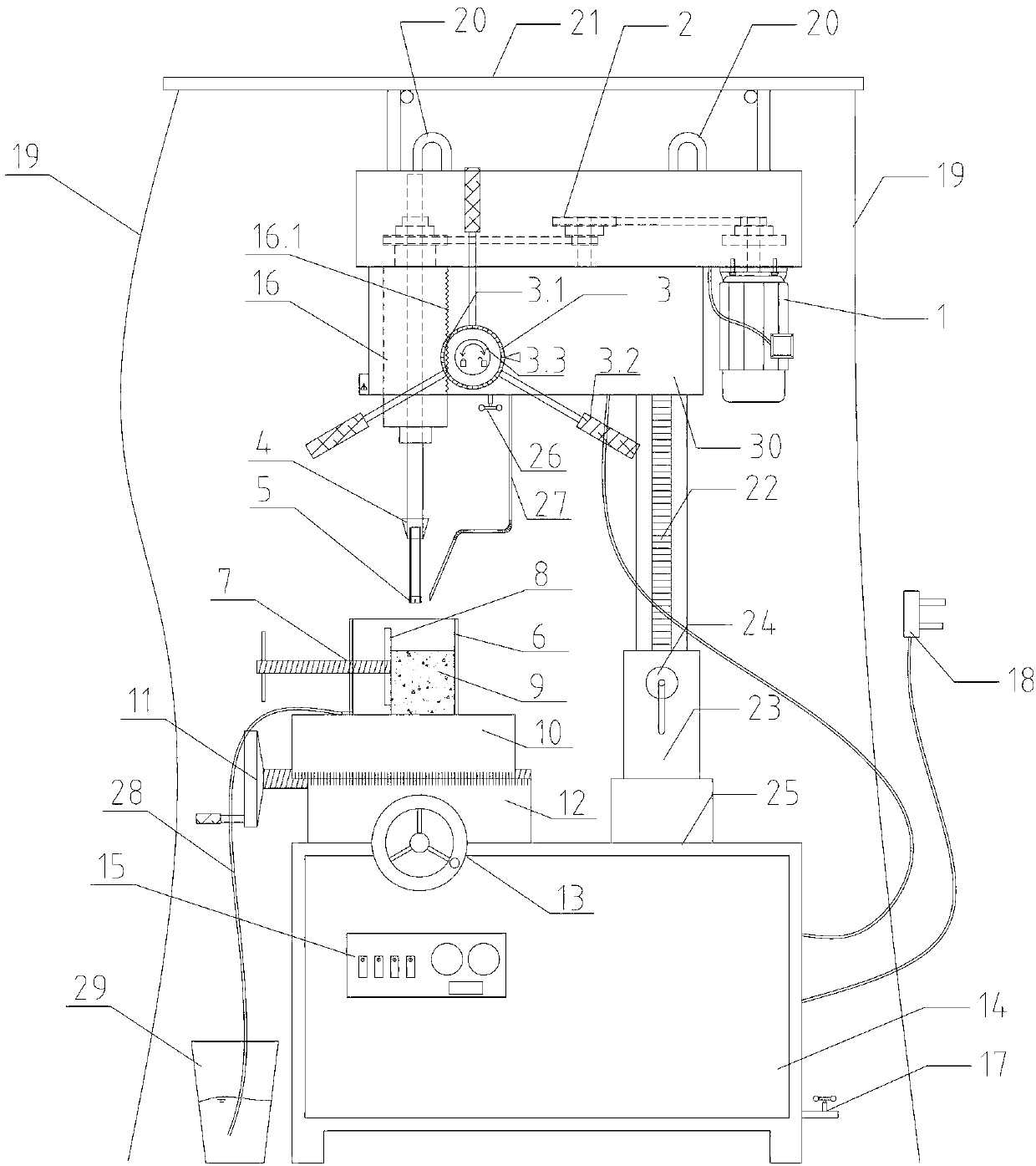

[0026] Such as figure 1 Shown is the multifunctional high-precision hardened concrete specimen processing machine of the present invention, which includes: frame, motor and gearbox, rotating shaft, drill bit, specimen holder, specimen clamping device, vertical lifting mechanism, specimen Horizontal movement mechanism and so on.

[0027] The bottom of the frame is a power control box 14, and a control panel 15 is installed on the surface of the power control box 14. The top of the power control box 14 is provided with a height adjustment base 25 , a toothed rigid pillar 22 , a height adjuster 23 and an adjustment handle 24 thereof. A motor and a gearbox are installed on the top of the toothed rigid pillar 22 . A dust cover support 21 is installed on the top of the frame.

[0028] A three-phase AC motor 1 is connected with a liftable rotating shaft 4 through a belt pulley transmission gearbox 2 . The lifting rotating shaft 4 can control the lifting height with high precision...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com