Microscopic Infrared Reflectance Spectrum Identification Method of Pearl Powder and Shell Powder

A reflection spectrum and micro-infrared technology, applied in the field of identification of pearl powder and shell powder, can solve the problems of outstanding influence on the identification of characteristic peak strength, insufficient effect, complicated identification process, etc., to achieve non-destructive testing, high efficiency and non-destructive The effect of detection and operation is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The microscopic infrared reflection spectrum identification of pearl powder and shell powder comprises the following steps:

[0038] (1) Sample preparation

[0039] (1.1) Prepare pearl powder and shell powder samples. The specific operation is: take 50g of pearls and 50g of mother-of-pearl and wash, crush, and grind them with a ball mill to make samples of pearl powder and shell powder to be identified;

[0040] (1.2) Take 1g each of the pearl powder and shell powder samples obtained in step (1.1) and spread them evenly in a crucible for calcination. The calcination temperature is 400°C and the calcination time is 30 minutes;

[0041] (1.3) Transfer the pearl powder and shell powder samples calcined in step (1.2) to a desiccator respectively, cool to room temperature and then grind;

[0042] (2) Infrared reflection spectrum detection

[0043] Using a Fourier transform micro-infrared spectrometer (ThermoScientificNicoletiN10MX), take 5 mg of each of the pearl powder an...

Embodiment 2

[0057] Sampling is carried out the microscopic infrared reflection spectrum identification of pearl powder and shell powder, and basic method and detection condition are the same as embodiment 1, and difference is:

[0058] In step (1.2), take 1g each of the pearl powder and shell powder samples obtained in step (1.1) and spread them evenly in a crucible for calcination. The calcination temperature is 380°C and the calcination time is 30 minutes;

[0059]In the step (2), the sample dosage of the pearl powder and shell powder samples obtained in the step (1.1) and the step (1.3) to be tested by infrared reflectance spectrum is 8 mg.

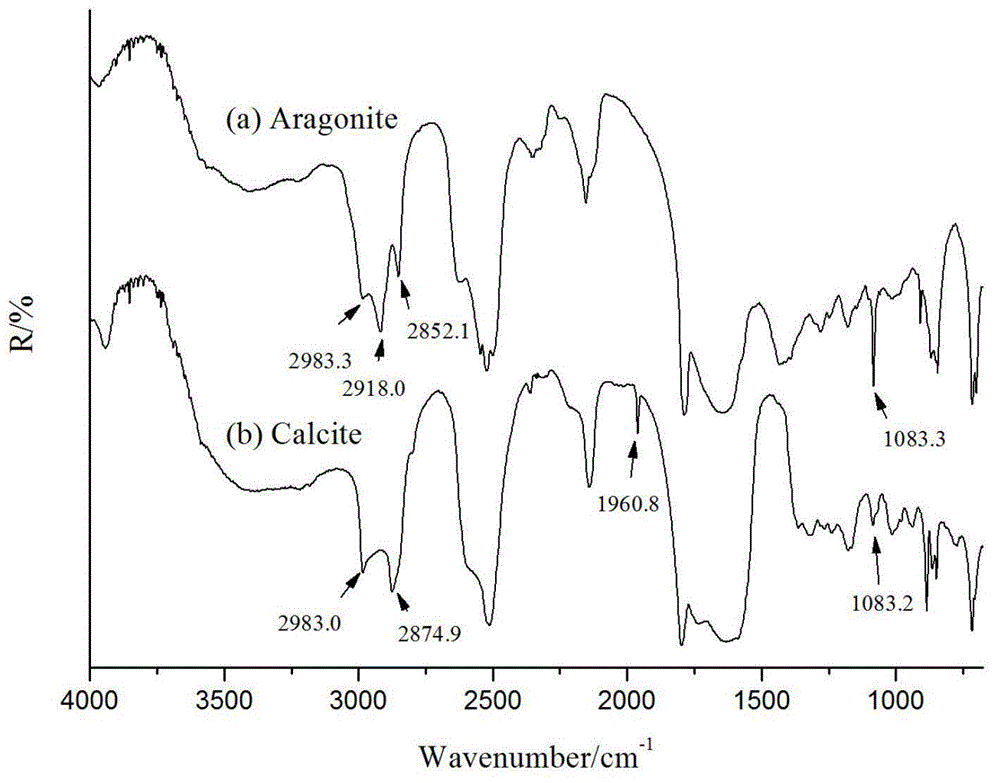

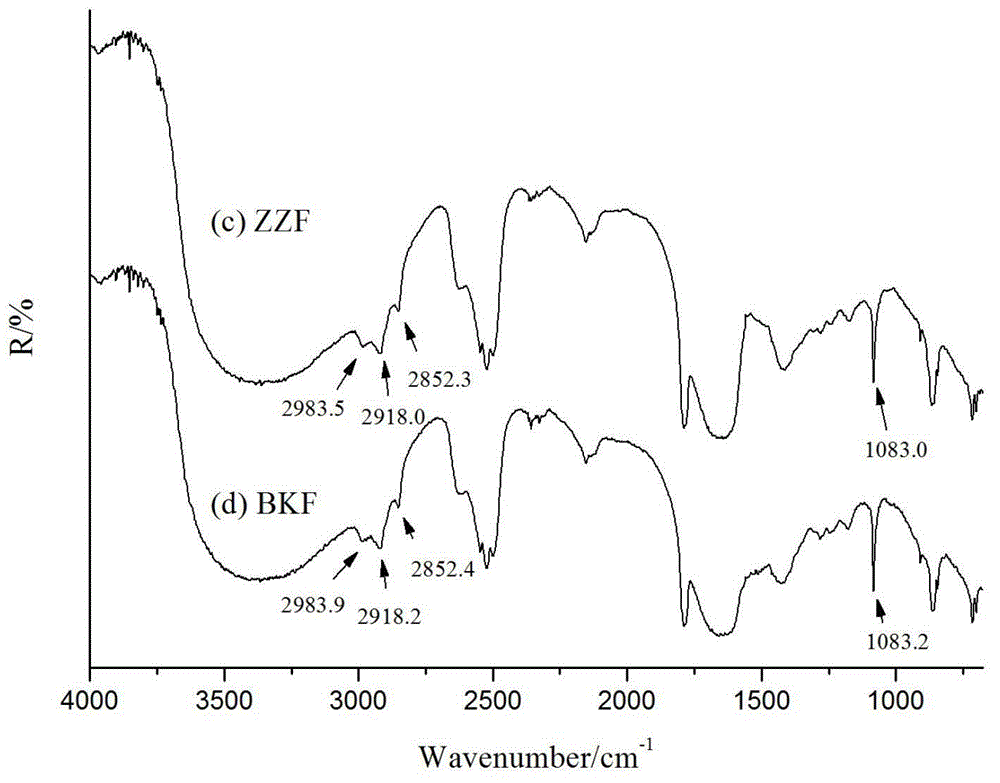

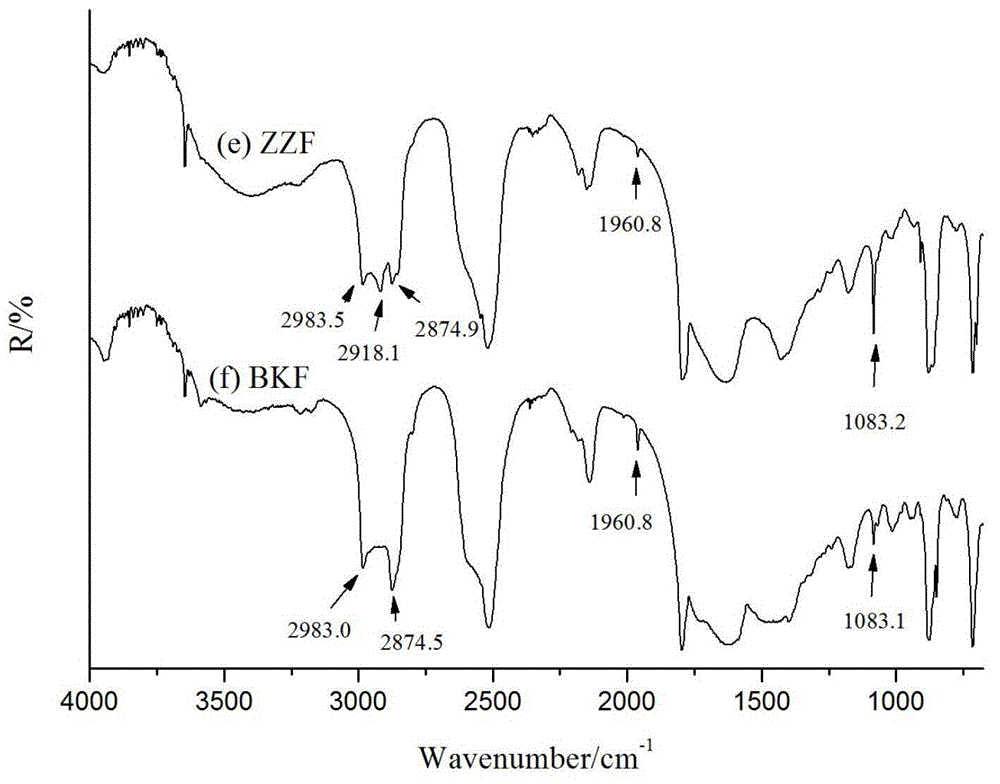

[0060] Specific test results such as Figure 4 and Figure 5 As shown, the characteristic infrared reflectance spectra of pearl powder and shell powder without calcination treatment at room temperature (RT) and calcination treatment are compared and analyzed, and the analysis method is the same as in Example 1. Such as Figure 4 and Figure 5 ...

Embodiment 3

[0062] Sampling is carried out the microscopic infrared reflection spectrum identification of pearl powder and shell powder, and basic method and detection condition are the same as embodiment 1, and difference is:

[0063] In step (1.2), take 1g each of the pearl powder and shell powder samples obtained in step (1.1) and spread them evenly in a crucible for calcination. The calcination temperature is 390°C and the calcination time is 30 minutes;

[0064] In the step (2), the sample dosage of the pearl powder and shell powder samples obtained in the step (1.1) and the step (1.3) to be tested by infrared reflectance spectrum is 10 mg.

[0065] Specific test results such as Figure 4 and Figure 5 As shown, the characteristic infrared reflectance spectra of pearl powder and shell powder without calcination treatment at room temperature (RT) and calcination treatment are compared and analyzed, and the analysis method is the same as in Example 1. Such as Figure 4 and Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com