Package based on technology that frame is connected through bonding wires and manufacturing process of package

A connection technology and manufacturing process technology, which is applied in the field of the package and its manufacturing process based on the frame-based bonding wire connection technology, can solve the problems of high cost, limited arrangement density of bumps, long design and manufacturing cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

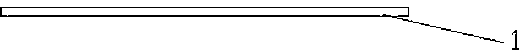

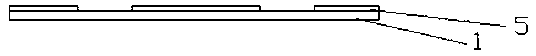

[0024] Such as Figure 12 As shown, a frame-based package using bonding wire connection technology includes a chip 3 , a plastic package 4 , a silver plating layer 5 and a bonding wire 6 . The silver-plated layer 5 is a mutually independent silver-plated layer segment, and there is a chip 3 on part of the silver-plated layer 5, and the chip 3 and the part of the silver-plated layer 5 without the chip 3 are connected by a bonding wire 6, surrounded by a plastic package 4 The chip 3, the silver-plated layer 5 and the bonding wire 6 constitute the power supply and signal channel of the circuit.

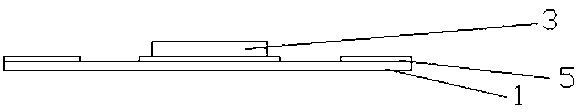

[0025] Such as Figure 8 As shown, a frame-based package using bonding wire connection technology also includes metal bumps 2 . The silver-plated layer 5 is a mutually independent silver-plated layer section, a part of the silver-plated layer 5 has a chip 3 on it, and a part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com