Liquor-marinated fish and production process thereof

A production process, the technology of drunken fish, applied in the fields of application, food preparation, food science, etc., can solve the problems of easy corruption and short shelf life of drunken fish products, and achieve the effect of long storage period, thorough sterilization, and fresh taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

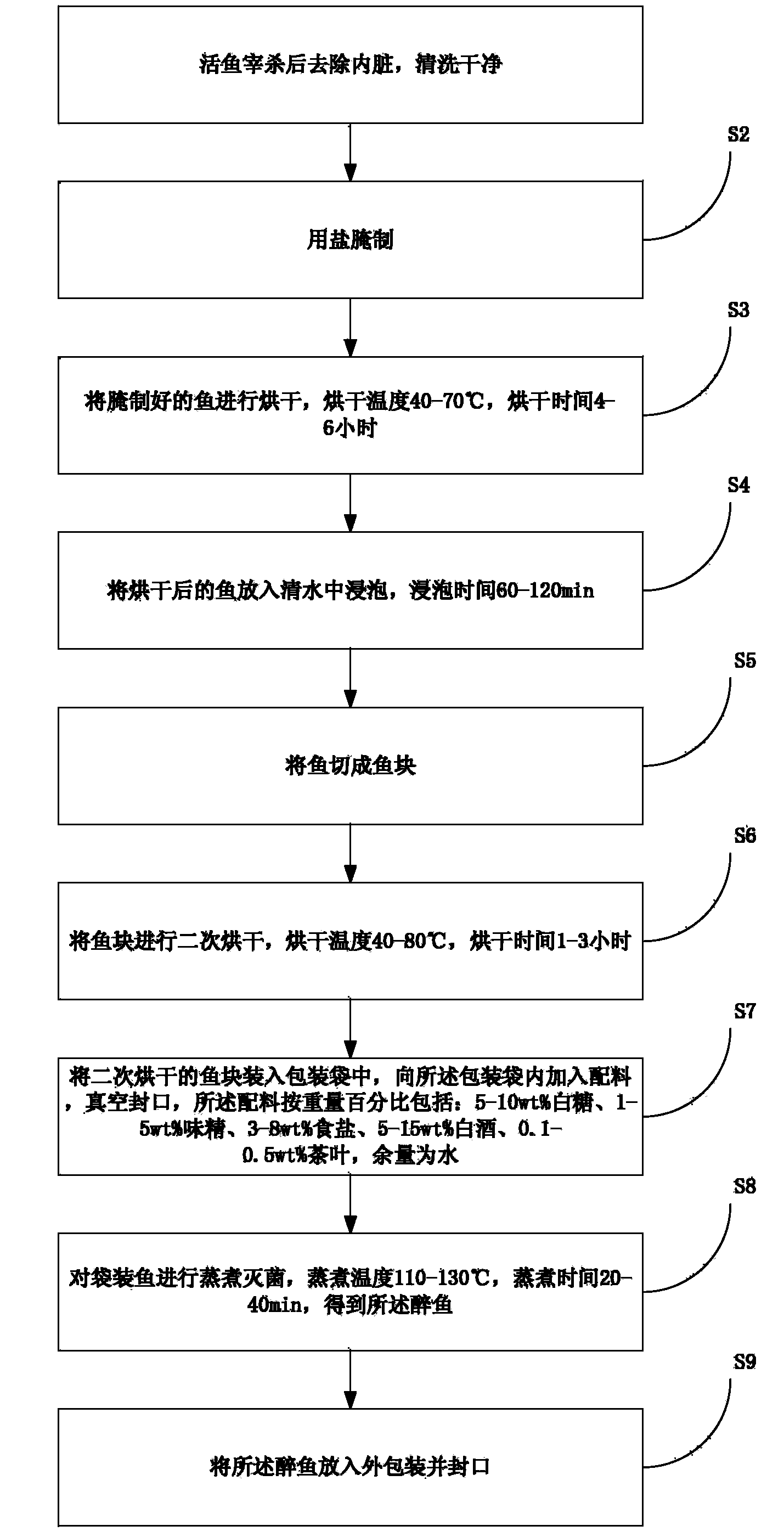

[0036] S1. After the live fish is slaughtered, remove the viscera and clean it;

[0037] S2, marinating with salt;

[0038] S3, drying the marinated fish, the drying temperature is 40°C, and the drying time is 6 hours;

[0039] S4, soak the dried fish in clear water for 60 minutes;

[0040] S5, the fish is cut into fish pieces;

[0041] S6. Drying the fish pieces for the second time, the drying temperature is 40°C, and the drying time is 3 hours;

[0042] S7. Put the fish nuggets dried for the second time into a packaging bag, add ingredients into the packaging bag, and vacuum seal the bag. The ingredients include: 5wt% white sugar, 1wt% monosodium glutamate, 3wt% salt, 5wt% Liquor, 0.1wt% tea leaves, the balance being water;

[0043] S8. Cooking and sterilizing the bagged fish at a cooking temperature of 110° C. for 40 minutes to obtain the drunken fish.

[0044] S9. Put the drunken fish into the outer package and seal it.

Embodiment 2

[0046] S1. After the live fish is slaughtered, remove the viscera and clean it;

[0047] S2, marinating with salt;

[0048] S3, drying the marinated fish, the drying temperature is 70°C, and the drying time is 4 hours;

[0049] S4. Soak the dried fish in clear water for 60-120 minutes;

[0050] S5, the fish is cut into fish pieces;

[0051] S6. Drying the fish pieces for the second time, the drying temperature is 80°C, and the drying time is 1 hour;

[0052] S7. Put the fish nuggets dried for the second time into a packaging bag, add ingredients into the packaging bag, and vacuum seal the bag. The ingredients include: 10wt% white sugar, 5wt% monosodium glutamate, 8wt% salt, 15wt% Liquor, 0.5wt% tea;

[0053] S8. Cooking and sterilizing the bagged fish at a cooking temperature of 130° C. for 20 minutes to obtain the drunken fish.

[0054] S9. Put the drunken fish into the outer package and seal it.

Embodiment 3

[0056] S1. After the live fish is slaughtered, remove the viscera and clean it;

[0057] S2, marinating with salt;

[0058] S3, drying the marinated fish, the drying temperature is 55°C, and the drying time is 5 hours;

[0059] S4. Soak the dried fish in clear water for 60-120 minutes;

[0060] S5, the fish is cut into fish pieces;

[0061] S6. Drying the fish pieces for the second time, the drying temperature is 55°C, and the drying time is 2 hours;

[0062] S7. Put the fish pieces dried for the second time into a packaging bag, add ingredients to the packaging bag, and vacuum seal the bag. The ingredients include: 8wt% white sugar, 3wt% monosodium glutamate, 5wt% salt, 10wt% Liquor, 0.2wt% tea;

[0063] S8. Cooking and sterilizing the bagged fish at a cooking temperature of 121° C. and cooking time of 31 minutes to obtain the drunken fish;

[0064] S9. Put the drunken fish into the outer package and seal it.

[0065] The drunken fish prepared in the above embodiments h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com