Parquet ceramic tile and device and method for preparing parquet ceramic tile

A technology for preparing devices and ceramic tiles, which is applied to printing devices, printing, rotary printing machines, etc., can solve the problems of poor adhesiveness of tile adhesives, waste of leftover materials, discounted decorative effects, etc., and achieves easy transportation and paving. The effect of fast production change and three-dimensional clear pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

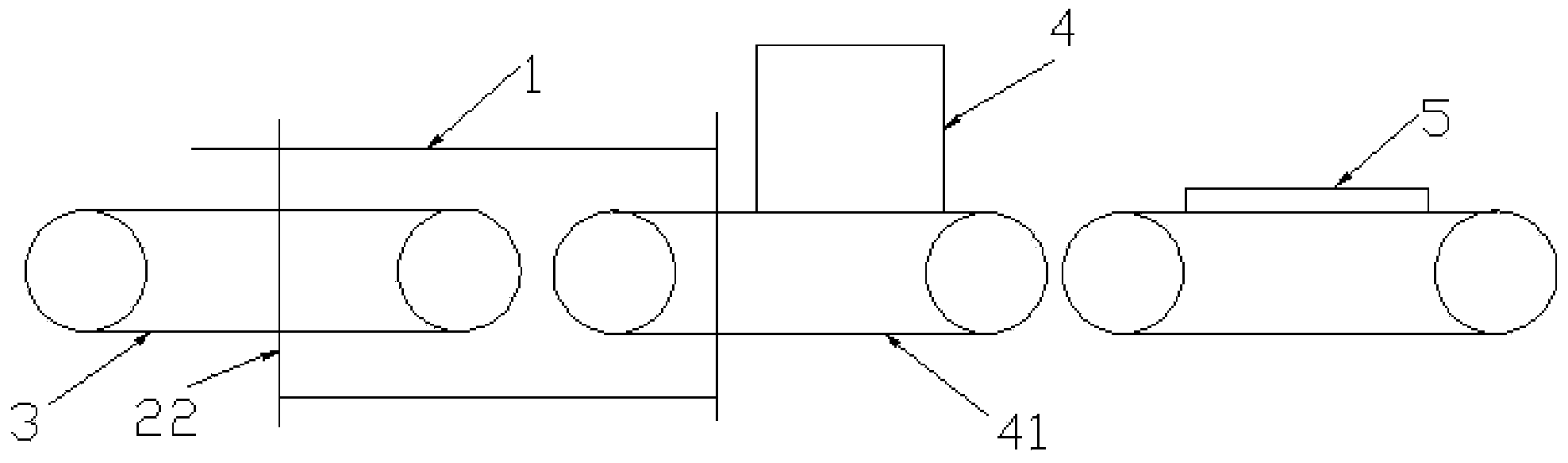

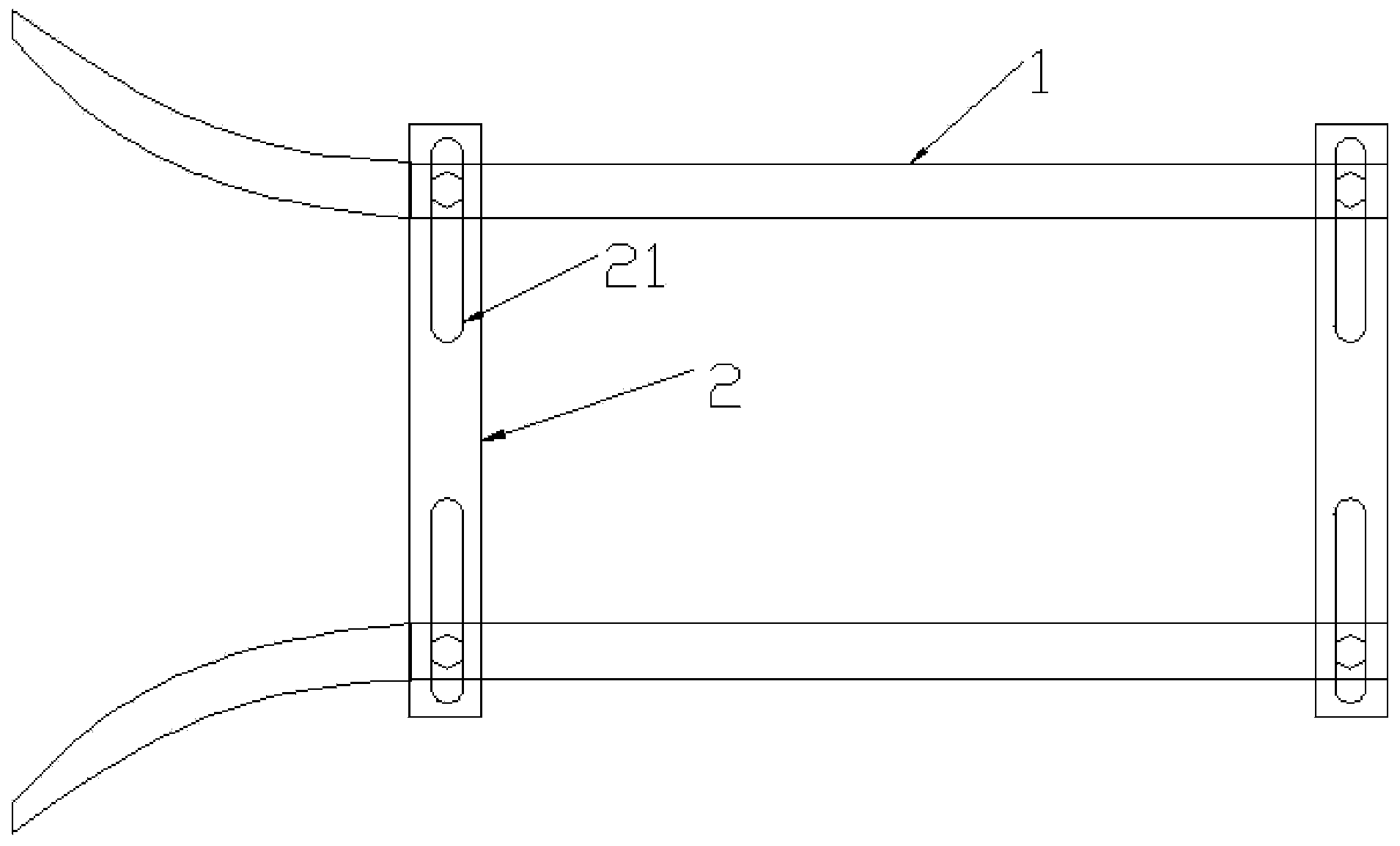

[0034] Combine figure 1 , figure 2 with image 3 As shown, a device for preparing mosaic ceramic tiles of the present invention,

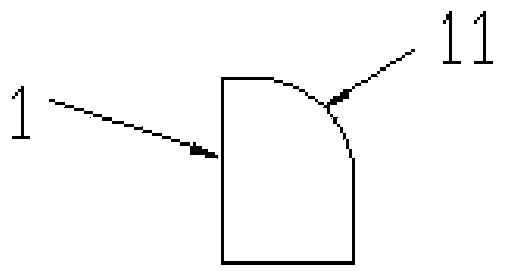

[0035] Including positioning baffle 1, baffle support 2, conveyor belt 3, inkjet printer 4, screen printing machine 5. The positioning baffle 1, the inkjet printer 4, and the screen printing machine 5 are sequentially arranged along the moving direction of the conveyor belt 3. The positioning baffle 1 is arranged in two pieces and is fixed and buckled on both sides of the conveyor belt 3 and the inkjet printer belt 41 by the baffle bracket 2. As the front end of the positioning baffle 1 is bent outward, Therefore, when the brick enters the positioning baffle, it can enter smoothly, avoiding bumps and causing product corners. The baffle bracket 2 is provided with a slide rail that can adjust the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com