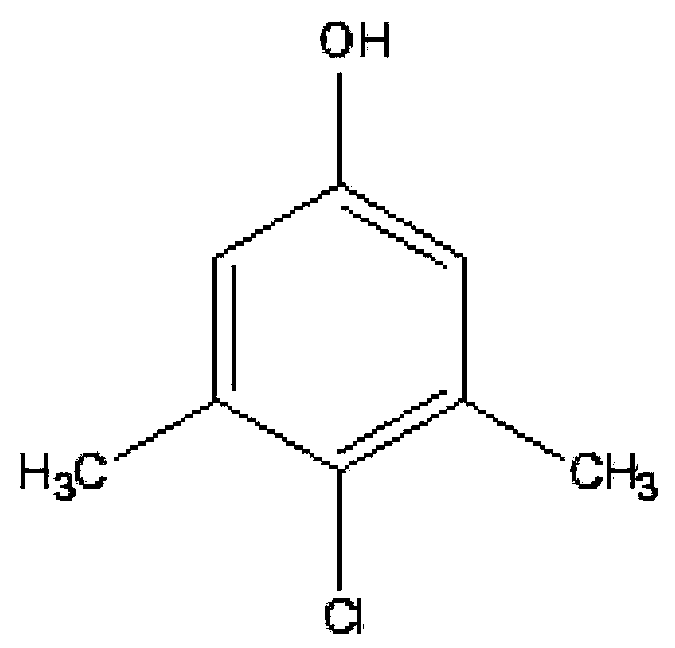

Preparation method of parachlorometaxylenol

A technology of p-chloro-meta-xylenol and dimethylphenol, applied in the field of basic chemical industry, can solve the problems of unclear industrialization prospect, long reaction time, large energy consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention proposes a kind of preparation method of p-chloro-m-xylenol, which comprises the following steps or operations.

[0029] Step 1, compounding water, inorganic acid and organic solvent into M system. The M system here is an abbreviation for the compound solution made of water, inorganic acid and organic solvent. The following solutions A, B, etc. are also referred to as abbreviations.

[0030] In one embodiment, this step can be specifically performed as follows: water, inorganic acid and organic solvent are compounded into an M system, wherein the inorganic acid is selected from hydrochloric acid with a mass concentration of 10-35% or 10-40% Any one of the sulfuric acid, the product yield of the sulfuric acid system is slightly better than that of the hydrochloric acid system; the organic solvent is selected from any one of tetrachlorethylene or ethylene dichloride; the inorganic acid and the 3,5- The weight ratio of dimethylphenol is 0.25:1~10:1,...

Embodiment 1

[0047] Add 300g of 10% hydrochloric acid and 30g of tetrachlorethylene into a 500ml three-necked flask to prepare the M system, add 122g of 3,5-dimethylphenol into the M system, then start the stirring or mixing device, and keep warm at 15- Between 25°C, slowly add 135g of sulfuryl chloride dropwise at this temperature, the dropping time is 4 hours, after the dropwise addition is completed, the temperature is raised to 85°C, and then cooled to 25°C, standing for stratification, and the lower organic phase is separated, the result For: 3,5-dimethylphenol: 1.78%, 4-chloro-3,5-dimethylphenol: 86.43%, 2-chloro-3,5-dimethylphenol: 9.84% and 2,4- Dichloro-3,5-dimethylphenol: 1.56%.

[0048] The material was suction filtered and washed with water, and dried to obtain 123g of white crystalline solid. The results of gas chromatography analysis were: 3,5-dimethylphenol: 0.51%, 4-chloro-3,5-dimethylphenol: 99.01%, 2 -Chloro-3,5-dimethylphenol: 0.23% and 2,4-dichloro-3,5-dimethylphenol: ...

Embodiment 2

[0050] Add 300g of 20% hydrochloric acid and 30g of dichloroethane into a 500ml three-necked flask to prepare the M system, add 122g of 3,5-dimethylphenol into the M system, then start the stirring or mixing device, and keep warm at 15- Between 25°C, slowly add 135g of sulfuryl chloride dropwise at this temperature, and the dropping time is 5 hours. After the dropwise addition is completed, the temperature is raised to 85°C, and then cooled to 25°C. For: 3,5-dimethylphenol: 0.88%, 4-chloro-3,5-dimethylphenol: 89.21%, 2-chloro-3,5-dimethylphenol: 8.45% and 2,4 -Dichloro-3,5-dimethylphenol: 1.23%.

[0051] The material was filtered and washed with water, and dried to obtain 123.3 g of white crystalline solids. The results of gas chromatography analysis were: 3,5-dimethylphenol: 0.52%, 4-chloro-3,5-dimethylphenol: 99.22%, 2-Chloro-3,5-dimethylphenol: 0.11% and 2,4-dichloro-3,5-dimethylphenol: 0.12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com