Processing technology of medium-wind-pressure percussion bit

A technology of impact drill and processing technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of long production process and high cost, save electricity and labor costs, and shorten the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

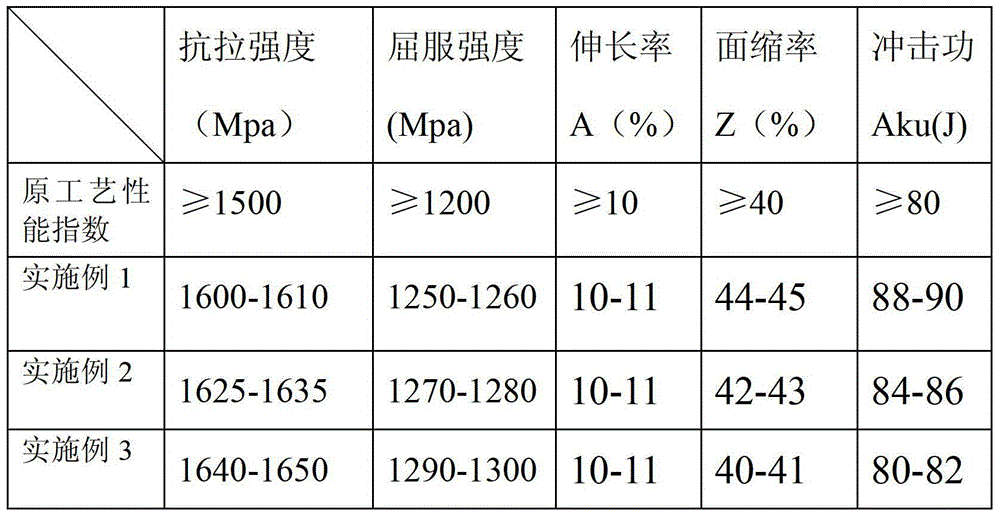

[0027] The drill bit of Z102-R45 type is produced, the material is annealed XGQ25 billet, the material composition is Cr:0.25, Ni:1.69, Mo:0.53, Mn:1.45, Si:1.39, V:0.21; after machining to the design size, Heating to 810-815°C, holding for 1 hour, the workpiece temperature is 815°C out of the furnace, placed in a closed quenching tank, the quenching tank has a volume of 1 cubic meter, and the speed of flowing nitrogen gas is 4 cubic meters per hour. The time required for the measured workpiece temperature to drop from 815°C to 550°C is 10 minutes, and the cooling rate of the workpiece is 20°C / s; It takes 20 minutes for ℃ to drop to 350 ℃, and the cooling rate of the workpiece is 10 ℃ / s; when the temperature of the workpiece reaches 350 ℃, the speed of flowing nitrogen gas is 3.5 cubic meters per hour. The time required is 40 minutes, and the cooling rate of the workpiece is 5°C / s; then, it is heated to 160-170°C for low-temperature tempering, and the tempering time is 2-3 hou...

Embodiment 2

[0029] The drill bit of Z102-R45 type is produced, the material is annealed XGQ25 billet, the material composition is Cr:0.25, Ni:1.69, Mo:0.53, Mn:1.45, Si:1.39, V:0.21; after machining to the design size, Heating to 817-822°C, holding for 1 hour, the workpiece temperature is 820°C out of the furnace, placed in a closed quenching tank, the quenching tank has a volume of 1 cubic meter, and the speed of flowing nitrogen gas is 4.5 cubic meters per hour. The time required for the measured workpiece temperature to drop from 820°C to 550°C is 8 minutes, and the cooling rate of the workpiece is 30°C / s; when the workpiece temperature reaches 550°C, the speed of flowing nitrogen gas is 4.0 cubic meters per hour, and the measured workpiece temperature is It takes 14 minutes for 550°C to drop to 350°C, and the cooling rate of the workpiece is 15°C / s; when the workpiece temperature reaches 350°C, the speed of flowing nitrogen gas is 3.8 cubic meters per hour, and the measured workpiece t...

Embodiment 3

[0031] The drill bit of Z102-R45 type is produced, the material is annealed XGQ25 billet, the material composition is Cr:0.25, Ni:1.69, Mo:0.53, Mn:1.45, Si:1.39, V:0.21; after machining to the design size, Heating to 825-830°C, keeping it warm for 1 hour, the workpiece temperature is 825°C, put it in a closed quenching tank, the volume of the quenching tank is 1 cubic meter, and the speed of flowing nitrogen gas is 4.8 cubic meters per hour. It takes 6 minutes for the measured workpiece temperature to drop from 825°C to 550°C, and the cooling rate of the workpiece is 35°C / s; when the workpiece temperature reaches 550°C, the speed of flowing nitrogen gas is 4.5 cubic meters per hour, and the measured workpiece temperature is from It takes 12 minutes for 550°C to drop to 350°C, and the cooling rate of the workpiece is 18°C / s; when the temperature of the workpiece reaches 350°C, the speed of flowing nitrogen gas is 4 cubic meters per hour, and the measured workpiece temperature d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com