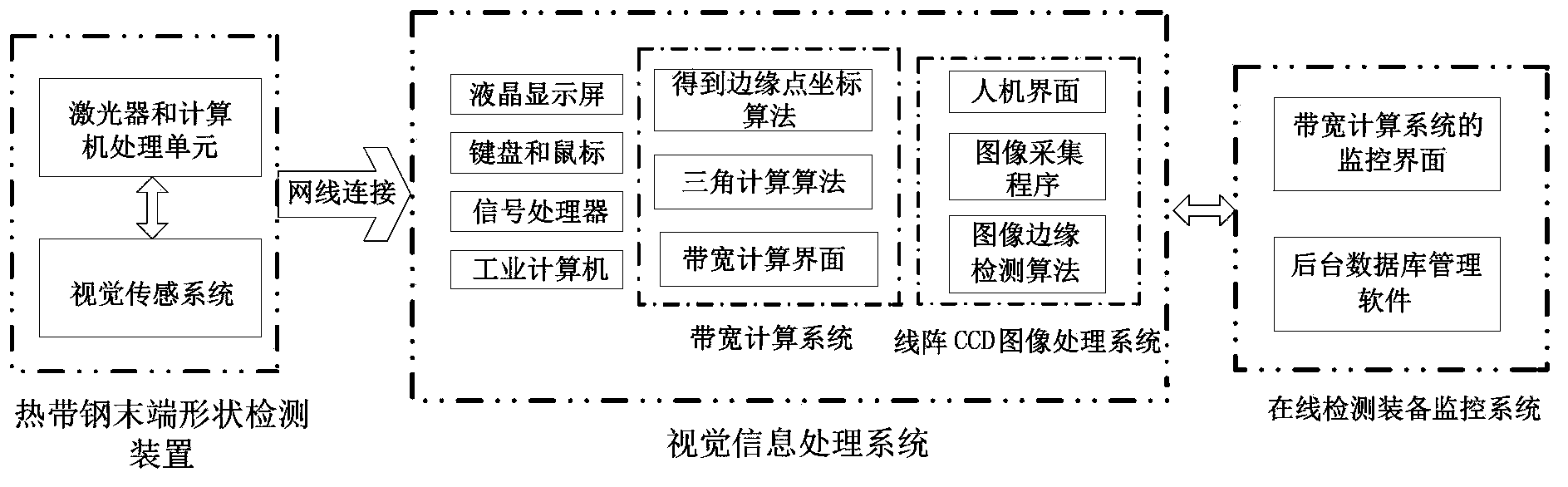

On-line vision measurement apparatus for end shapes of hot rolled strip steel

A technology for hot-rolled strip steel and visual measurement, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of insufficient precision, slow detection speed of strip end shape, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

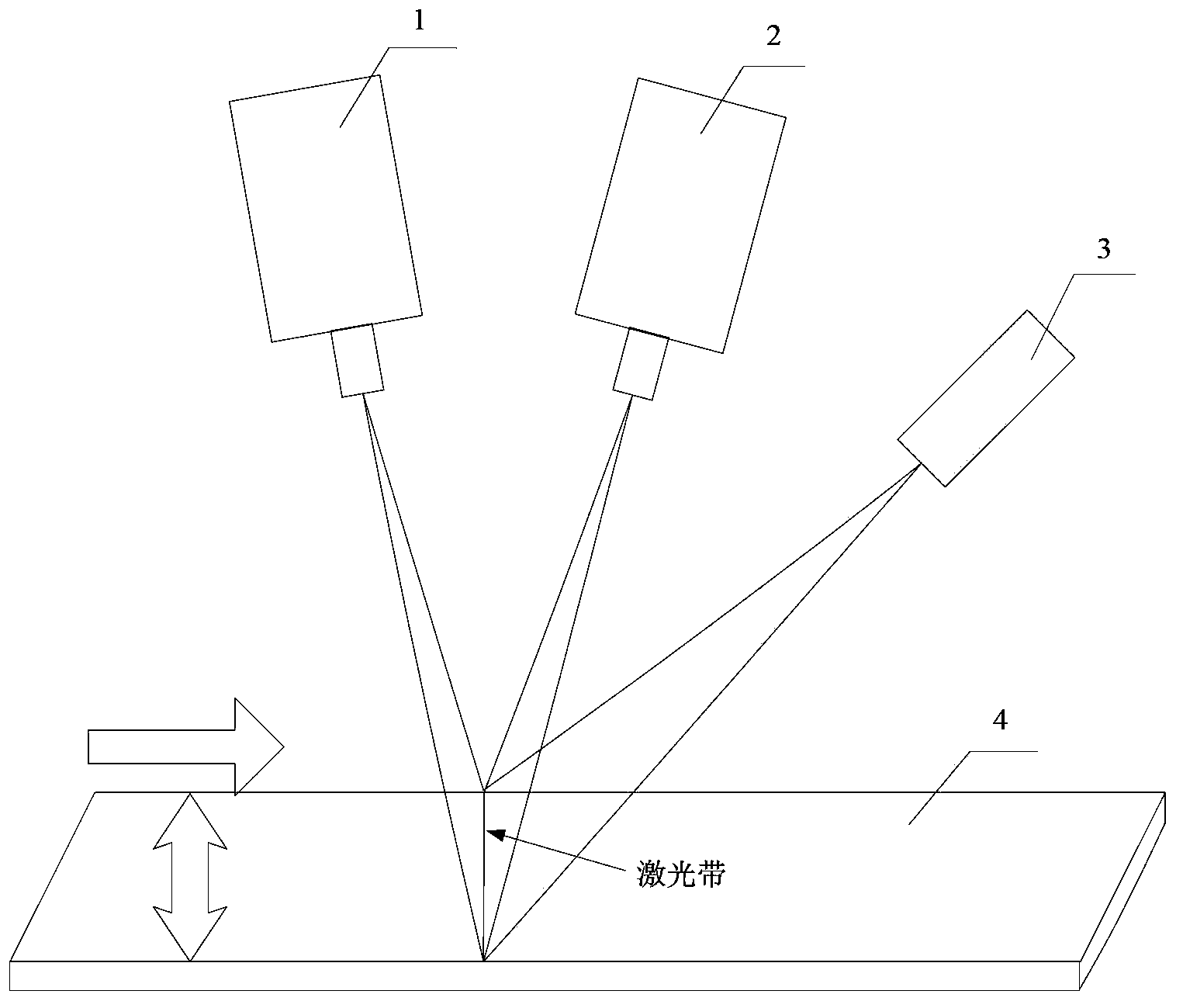

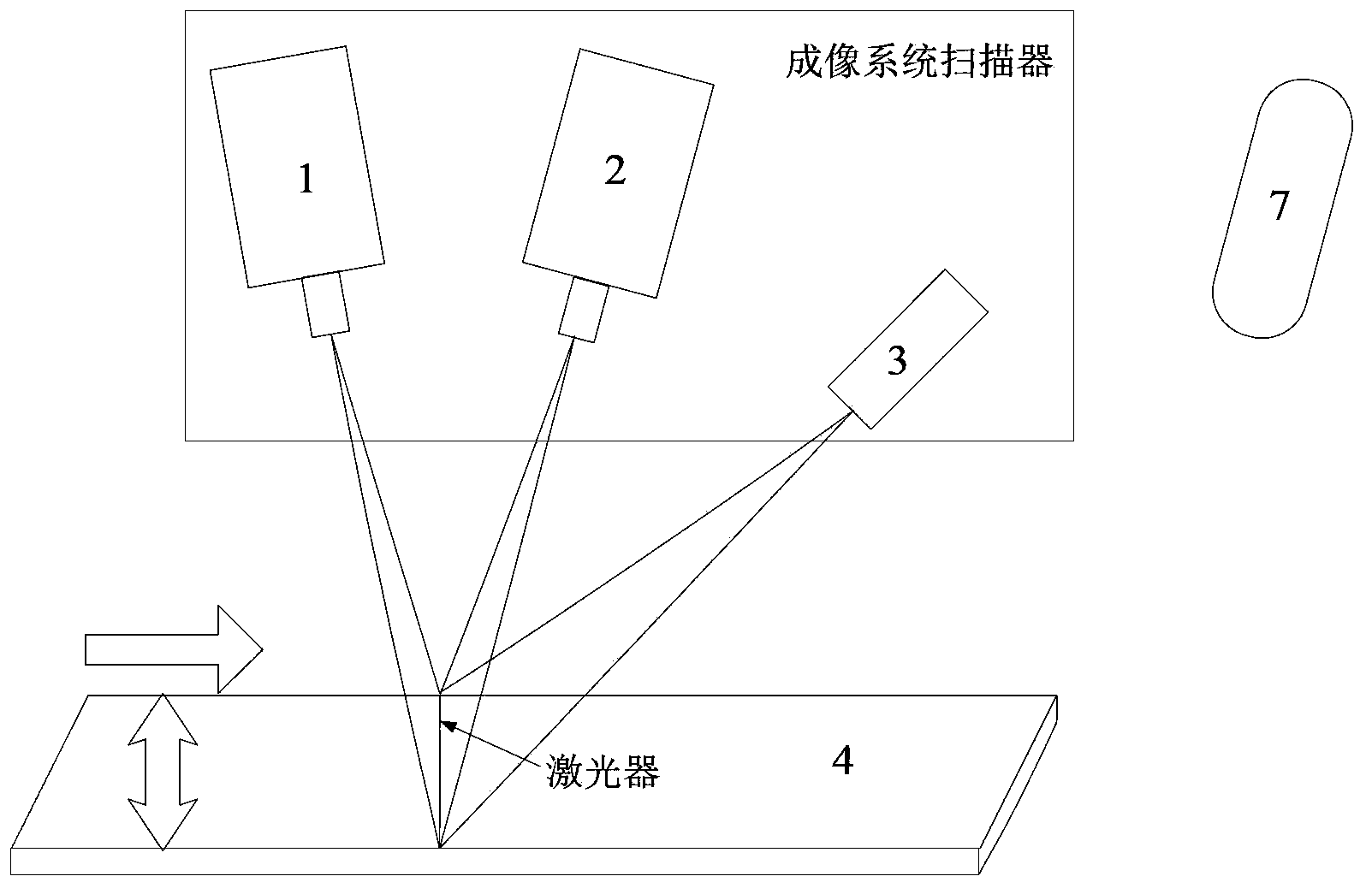

[0060] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 8 The on-line visual measuring device for the shape of the hot-rolled steel strip end of the assembly cost embodiment is composed of a linear CCD camera 1 on the left and a linear CCD camera 2 on the right to form a binocular vision system, and then the binocular vision system and a laser 3 The scanner of the imaging system is installed above the strip steel production line at an angle of 0 degrees, and the distance between the linear array CCD camera 1 and the linear array CCD camera 2 is 300 mm. The distance from the center line of the scanner of the imaging system to the center line of the reversible rolling mill 5 is 5878 mm. The scanner of the imaging system is installed on the steel structure platform at the exit of the reversible rolling mill 5. An insulating asbestos interlayer is designed under the platform, and steel plate fences are installed around the platform to iso...

Embodiment 2

[0077] Except that the scanner of the imaging system is installed above the strip production line at an angle of 45 degrees, and the distance between the linear CCD camera 1 and the linear CCD camera 2 is 450 mm, the others are the same as in Embodiment 1.

Embodiment 3

[0079] Except that the scanner of the imaging system is installed above the strip steel production line at an angle of 90 degrees, and the distance between the linear CCD camera 1 and the linear CCD camera 2 is 600 mm, the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com