Electromagnetic ultrasonic longitudinal guided wave and magnetic leakage detection compounded detection method

An electromagnetic ultrasonic and magnetic flux leakage detection technology, applied in the direction of material magnetic variables, etc., can solve the problems of different corrosion mechanisms, different treatment methods, disadvantages, etc., and achieve the effect of simple detection method, fast detection speed, and fast detection speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through specific embodiments.

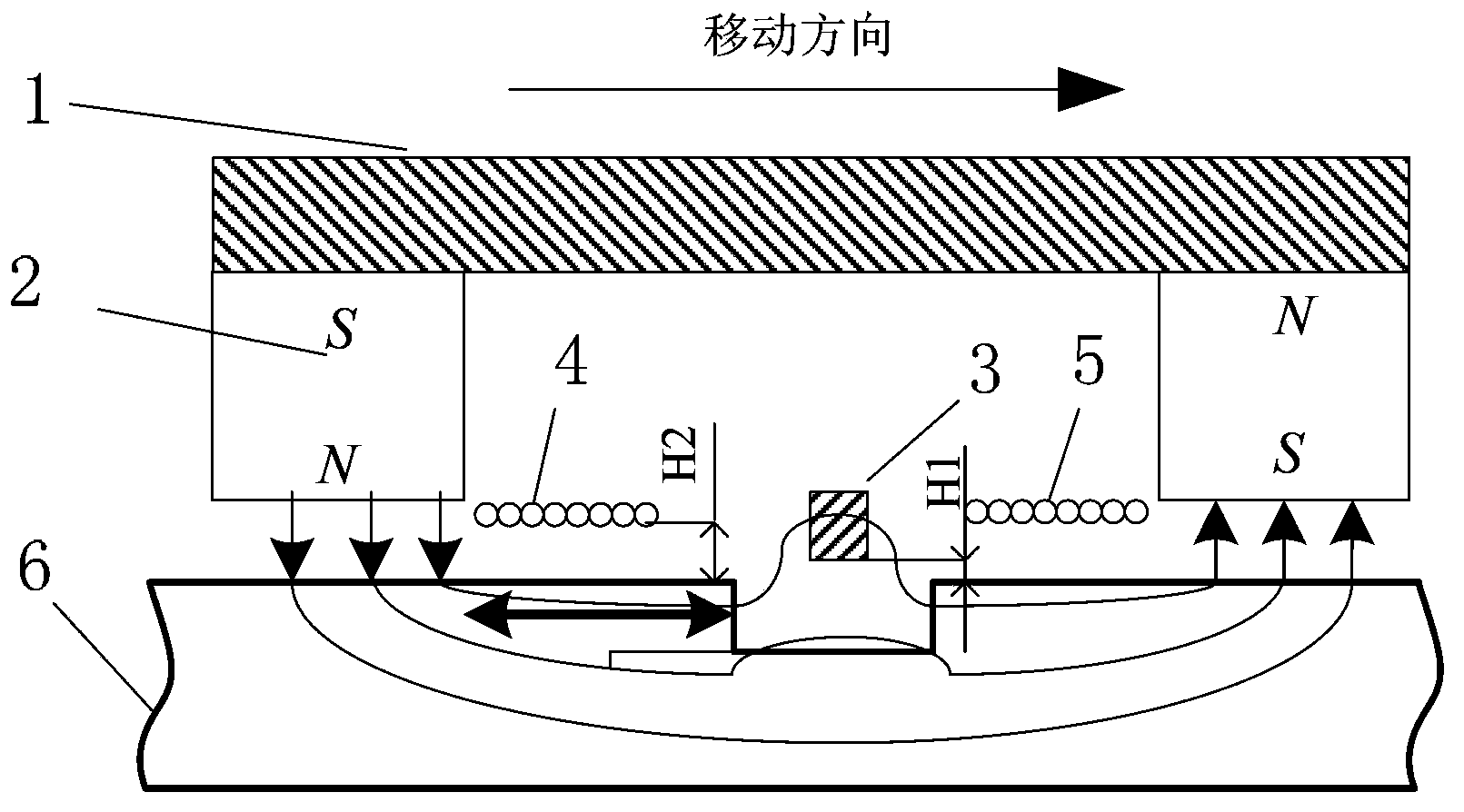

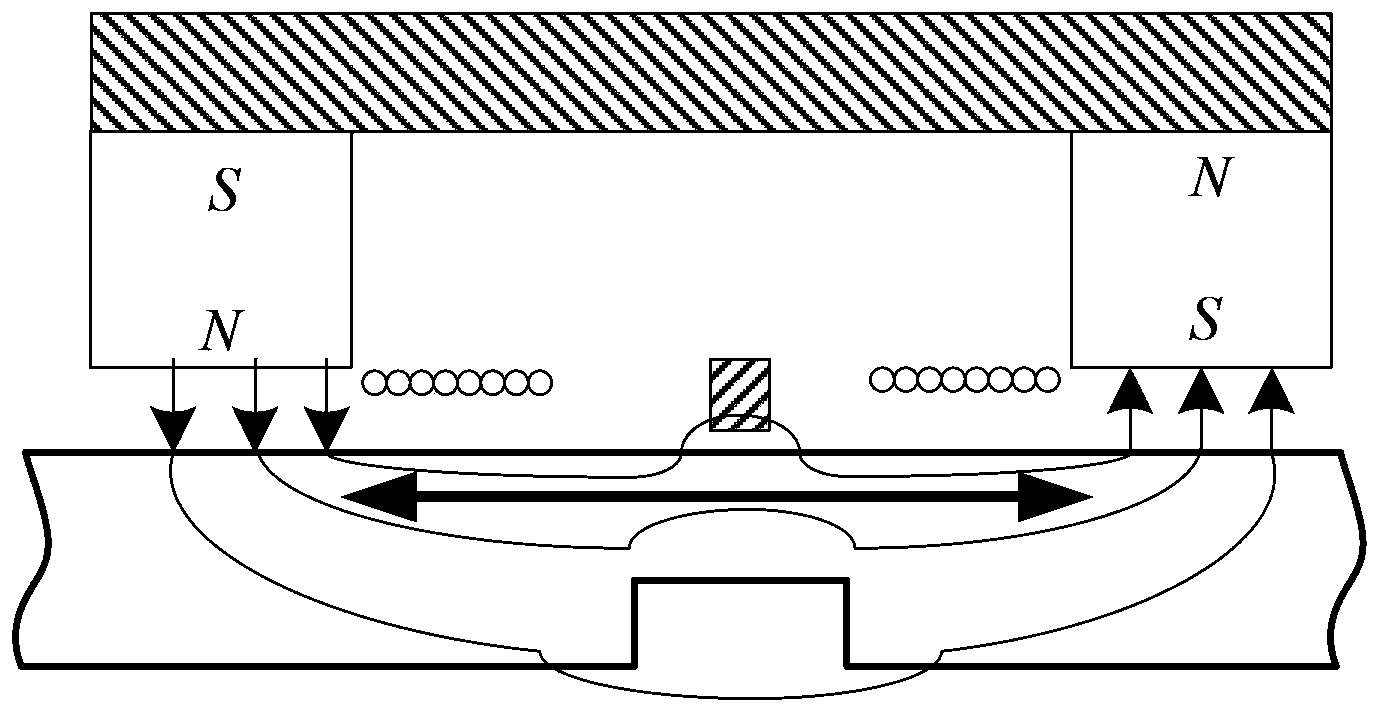

[0032] refer to figure 1 , figure 2 , is a schematic diagram of the probe device involved in the present invention, the probe device includes a magnetic flux leakage detection unit and an electromagnetic ultrasonic (EMAT) detection unit. Among them, the magnetic flux leakage detection unit is composed of a permanent magnet 2, a U-shaped magnetic core 1, and a Hall element 3; the electromagnetic ultrasonic (EMAT) detection unit is composed of a permanent magnet 2, a U-shaped magnetic core 1, an electromagnetic ultrasonic (EMAT) excitation coil 4, Electromagnetic ultrasonic (EMAT) receiving coil 5 is composed. The magnetic flux leakage detection unit is shared with the permanent magnet 2 and the U-shaped magnetic core 1 of the electromagnetic ultrasonic detection unit. The electromagnetic ultrasonic excitation coil 4 and the electromagnetic ultrasonic receiving coil 5 are placed insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com