Magnetic polylactic acid tissue engineering bracket

A tissue engineering scaffold, polylactic acid technology, applied in medical science, prosthesis and other directions, can solve the problems of cumbersome steps in the drug delivery process, and achieve the effect of reducing cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

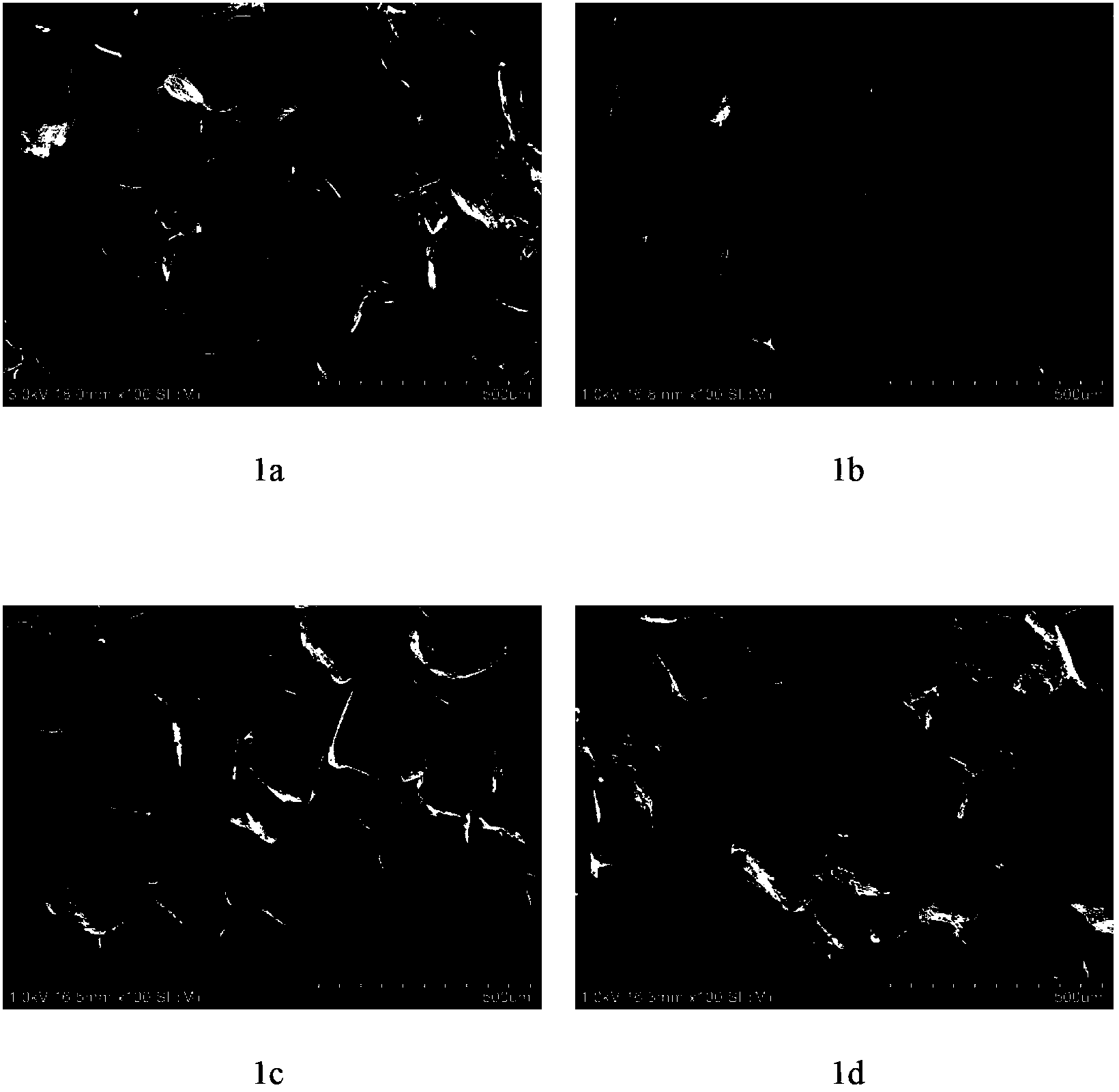

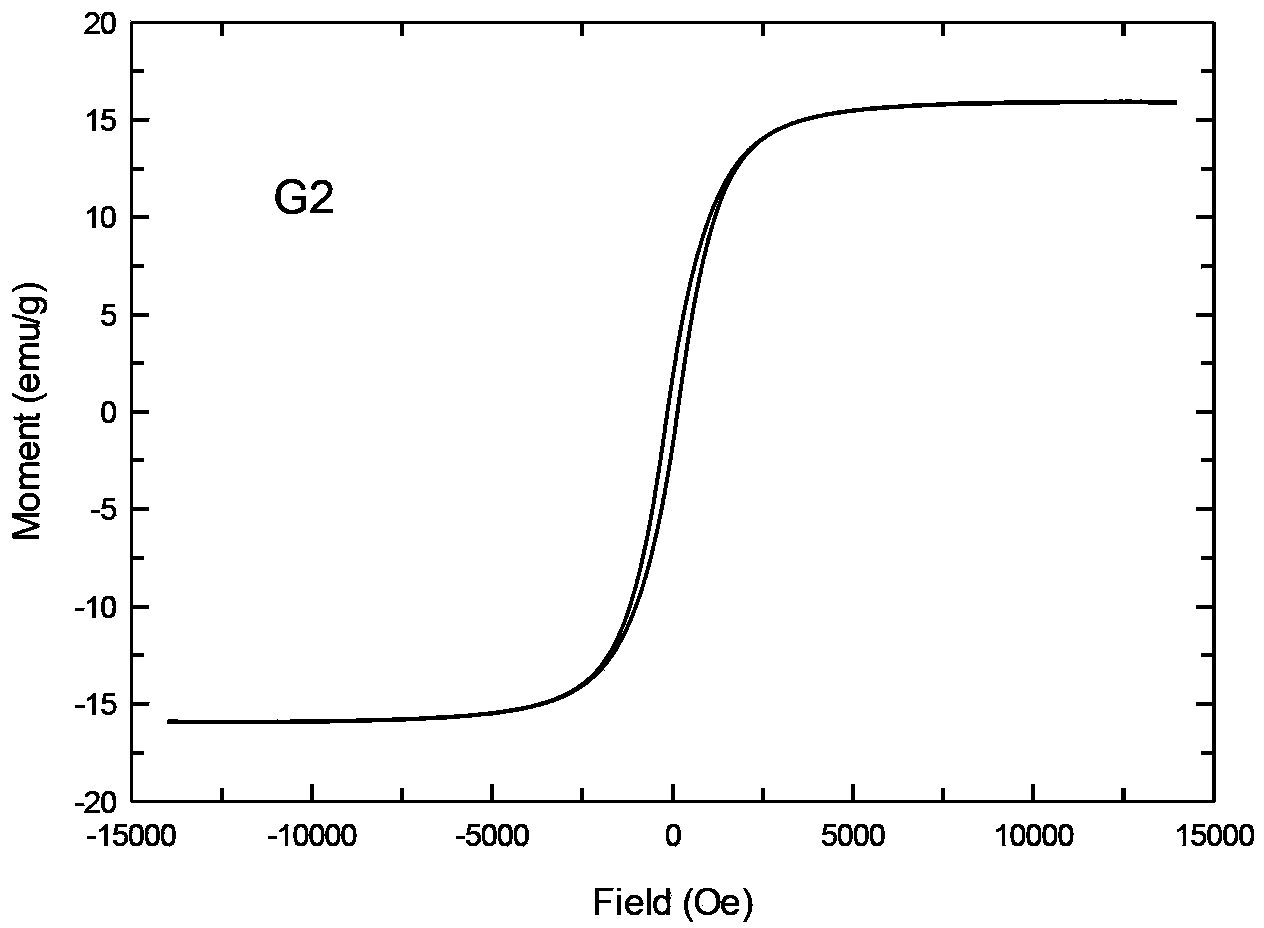

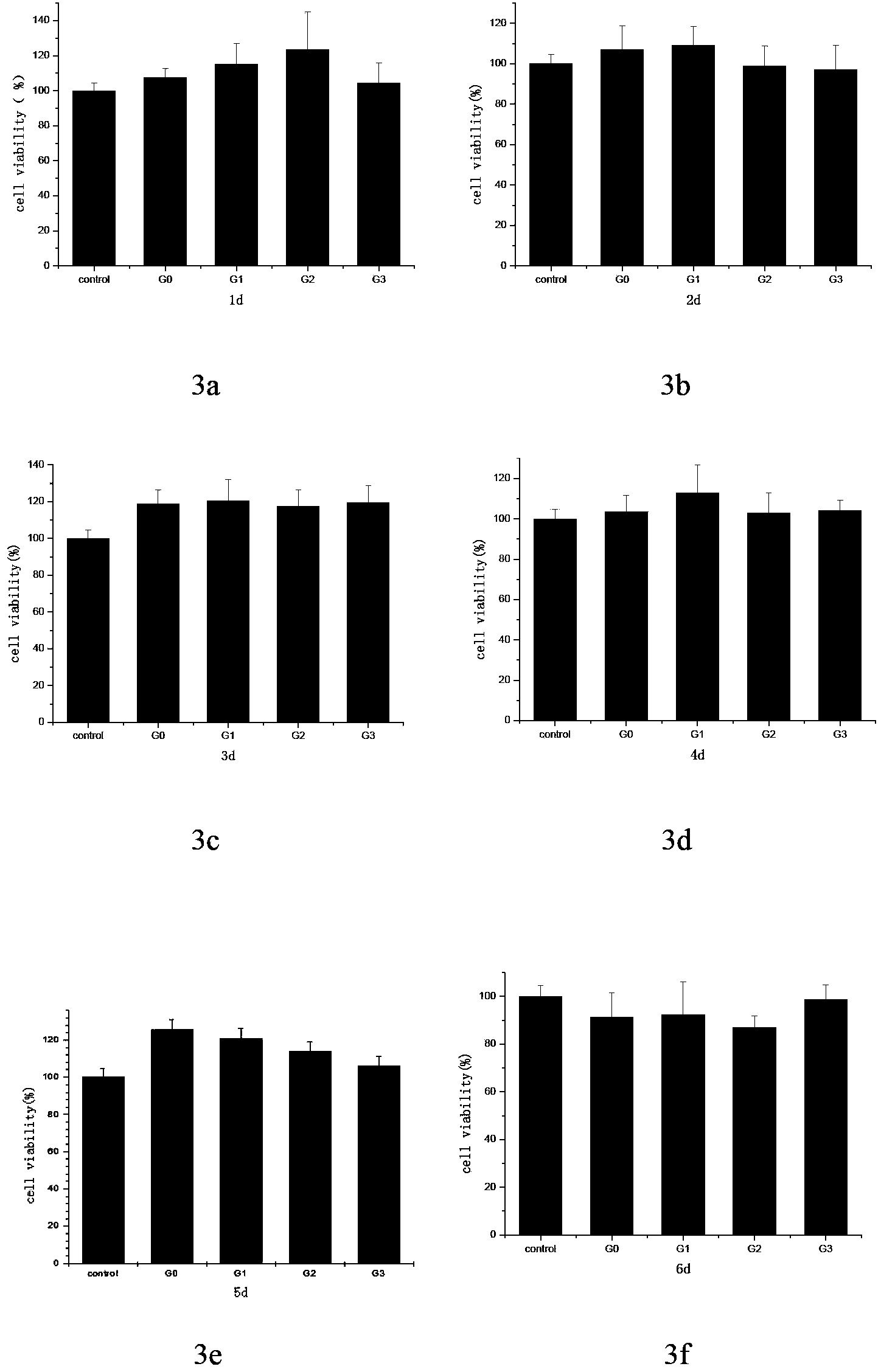

[0021] 2g of polyracemic lactic acid was dissolved in 20ml of methylene chloride, and 0.15g of Fe with particle size less than 50nm 3 o 4 The powder and 19g of NaCl with a particle size of 300-400 microns are mixed evenly, then added to the fully dissolved polyracemic lactic acid solution, stirred evenly, and poured into a mold. Let the solvent fully volatilize naturally, dry in vacuum at room temperature for 6 hours, add distilled water to fully leach, so that the porogen NaCl is dissolved, and the Fe-containing 3 o 4 polylactic acid magnetic tissue engineering scaffold.

Embodiment 2

[0023] 10g of poly-L-lactic acid is dissolved in 100ml of chloroform, and 2g of Fe with a particle size of less than 5 microns 3 o 4 The powder and 20g of NaCl with a particle size of 0-100 microns are mixed evenly, then added to the fully dissolved poly-L-lactic acid solution, stirred evenly, and the mixed solution is cast on a petri dish, and the chloroform is naturally volatilized in a fume hood at room temperature. membrane. Put the petri dish into a vacuum drying oven for 48 hours to vacuum dry. Then the film was taken out, crushed with a mortar, and the material was hot-pressed on a vulcanizer at 170° C. and a pressure of 15 MPa using a mold. Release the mold, wait for the temperature of the material to drop to room temperature, add distilled water to fully leach, so that the porogen NaCl is dissolved, and the Fe-containing 3 o 4 polylactic acid magnetic tissue engineering scaffold.

Embodiment 3

[0025] 5g poly-D-lactic acid was dissolved in 40ml methylene chloride, and 0.2g of Fe with a particle size less than 100nm 3 o 4 Add the powder into the fully dissolved poly-D-lactic acid solution, stir evenly, and put it into a vacuum freeze dryer after quick-freezing in liquid nitrogen, so that the solvent is fully volatilized, and the Fe-containing 3 o 4 Polycaprolactone Magnetic Scaffold for Tissue Engineering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com