Catalyst vulcanization method for diesel hydrotreating process

A hydrogenation treatment and catalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as joint operation of multiple hydrogenation units, and achieve considerable economic benefits and social Benefits, good vulcanization effect, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

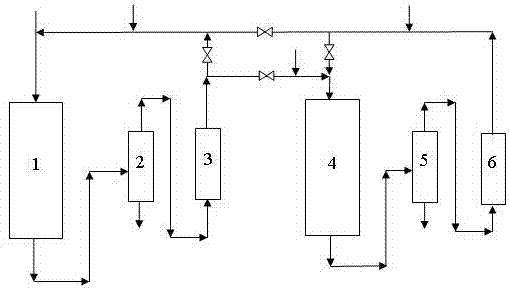

Embodiment 1

[0056] The high-sulfur diesel hydrotreating unit is in normal operation. Put catalysts A and B into the reactor of diesel oil upgrading (MCI) device 4, after gas replacement, catalyst drying and device airtightness, the hydrogen partial pressure is adjusted to 6.0MPa, ready to start vulcanization. Raise the temperature of the catalyst bed in reactor 4 of the diesel oil upgrading (MCI) unit to 150°C. After the bed temperature stabilizes, adjust the circulation hydrogen dehydrogenation unit 3 of the high-sulfur diesel hydrotreating unit, and introduce the circulation hydrogen containing hydrogen sulfide Diesel oil upgrading (MCI) device 4, for vulcanization, and then through the diesel oil upgrading (MCI) device reaction product gas-liquid separator 5, the gas enters the diesel oil upgrading (MCI) device circulating hydrogen dehydrogen sulfide device 6, for dehydrogen sulfide After treatment, return to the high-sulfur diesel hydrotreating unit 1. Establish a circulating hydroge...

Embodiment 2

[0058] The high-sulfur diesel hydrotreating unit is in normal operation. Put the catalysts A and B into the reactor of the diesel oil upgrading (MCI) device 4. After gas replacement, catalyst drying and device airtightness, the hydrogen partial pressure is adjusted to 6.0 MPa, ready to start vulcanization. Raise the temperature of the catalyst bed in reactor 4 of the diesel oil upgrading (MCI) unit to 130°C. After the bed temperature stabilizes, adjust the circulating hydrogen of the high-sulfur diesel hydrotreating unit to dehydrogen sulfide unit 3, and the circulating hydrogen containing hydrogen sulfide Introduce the diesel oil upgrading (MCI) device 4 for vulcanization, and then pass through the diesel oil upgrading (MCI) device reaction product gas-liquid separator 5, and the gas enters the diesel oil upgrading (MCI) device circulating hydrogen dehydrogen sulfide device 6 for desulfurization After hydrogen treatment, return to the high-sulfur diesel hydrotreating unit 1. ...

Embodiment 3

[0060] The high-sulfur diesel hydrotreating unit is in normal operation. Put catalysts A and B into reactor 4 of the diesel oil upgrading (MCI) device. After gas replacement, catalyst drying and device airtightness, the hydrogen partial pressure is adjusted to 6.0 MPa, ready to start vulcanization. Raise the temperature of the catalyst bed in reactor 4 of the diesel oil upgrading (MCI) unit to 160°C. After the bed temperature stabilizes, adjust the circulating hydrogen dehydrogen sulfide unit 3 of the high-sulfur diesel hydrotreating unit, and introduce the circulating hydrogen containing hydrogen sulfide into the Diesel oil upgrading (MCI) device 4, for vulcanization, and then through the diesel oil upgrading (MCI) device reaction product gas-liquid separator 5, enters the diesel oil upgrading (MCI) device circulating hydrogen dehydrogen sulfide device 6, for dehydrogen sulfide treatment Afterwards, return to the high-sulfur diesel oil hydrotreating unit 1. Establish a circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com