A compound chemical leaching method for repairing heavy metal polluted soil

A technology of polluted soil and chemical leaching, applied in the restoration of polluted soil, etc., can solve the problems of troublesome follow-up treatment, high cost of chemicals, large soil damage, etc., and achieve short washing time, low price and high restoration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

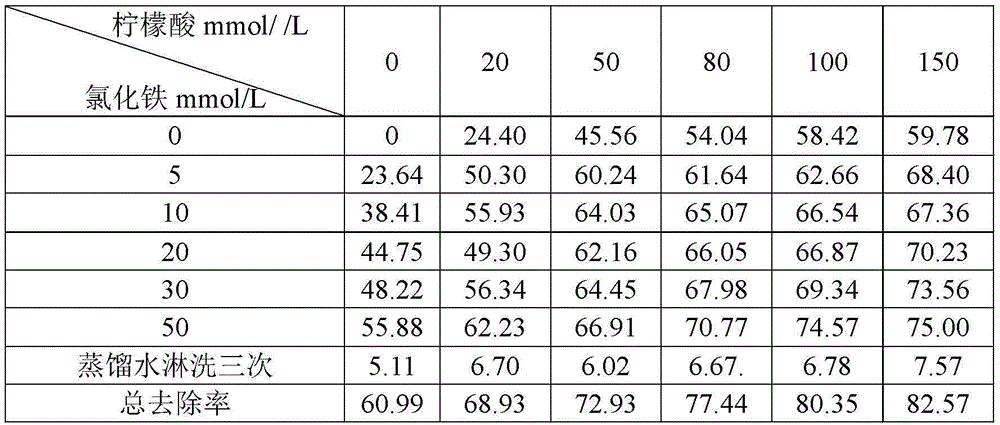

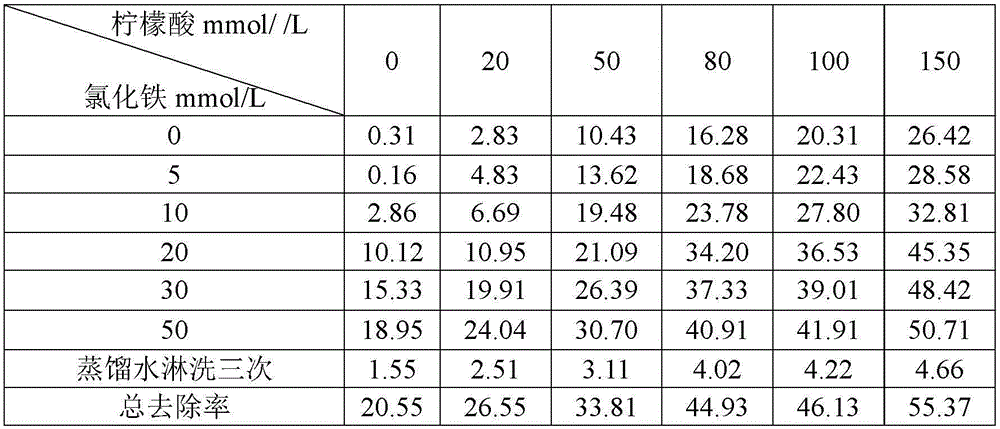

Embodiment 1

[0029] Heavy metal contaminated soil in Zhuzhou, Hunan Province (Cd content 6.68mg / kg, Pb content 787.76mg / kg), the contaminated soil was ground and passed through a 2mm sieve; several parts of soil were weighed, 5 grams each, placed in a centrifuge tube, each Add 10 mL of the composite eluent prepared by ferric chloride and citric acid, the concentrations of ferric chloride and citric acid in each composite eluent are shown in Table 1 and Table 2; place the centrifuge tube in a constant temperature shaker , control the washing temperature at 25°C, and the oscillation rate at 200 rpm. After 24 hours of oscillation washing, take out the centrifuge tube; place it in a centrifuge, centrifuge at a rate of 5000 rpm for 5 minutes, and pour off the composite washing tube. Wash solution; add 10mL of distilled water to the centrifuge tube, rinse at the same temperature, shaking rate and rinse time as above, then centrifuge at 5000 rpm for 5 minutes, pour off the supernatant; use distill...

Embodiment 2

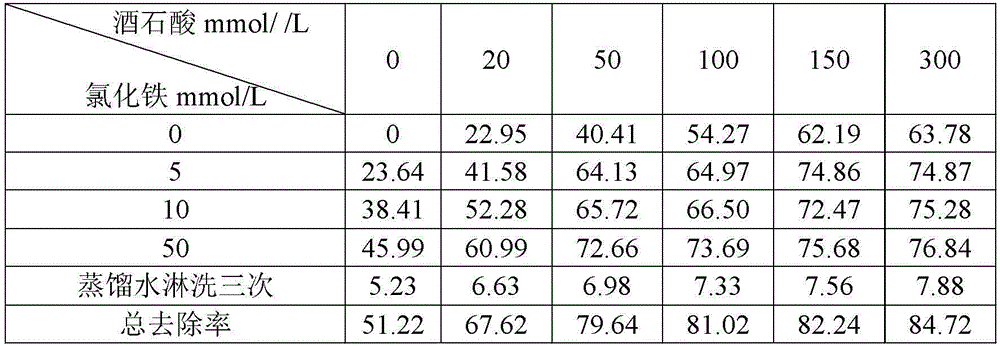

[0036]Heavy metal contaminated soil in Zhuzhou, Hunan Province (Cd content 6.68mg / kg, Pb content 787.76mg / kg), the contaminated soil was ground and passed through a 2mm sieve; several parts of soil were weighed, 5 grams each, placed in a centrifuge tube, each Add 10mL of composite eluent prepared by ferric chloride and citric acid, and the concentrations of ferric chloride and tartaric acid in each composite eluent are shown in Table 3 and Table 4; the centrifuge tube is placed in a constant temperature shaker, Control the rinsing temperature to 25°C, and the oscillation rate to 200 rpm. After 24 hours of oscillating rinsing, take out the centrifuge tube; place it in a centrifuge, centrifuge at 5000 rpm for 5 minutes, and pour off the combined rinsing Then add 10mL of distilled water to the centrifuge tube, the rinsing temperature, shaking rate and rinsing time are the same as above, then centrifuge at 5000 rpm for 5 minutes, pour off the supernatant; use distilled water under ...

Embodiment 3

[0043] Heavy metal contaminated soil in Zhuzhou, Hunan Province (Cd content 6.68mg / kg, Pb content 787.76mg / kg), the contaminated soil was ground and passed through a 2mm sieve; several parts of soil were weighed, 5 grams each, placed in a centrifuge tube, each Add the composite eluent 10mL that is prepared by ferric chloride and malic acid, the concentration of ferric chloride and malic acid in every part of composite eluent is as shown in table 5 and table 6; other test methods are the same as embodiment 1, get Repaired soil.

[0044] Table 5 Cd removal rate (%) in the washing process

[0045]

[0046] Pb removal rate (%) in table 6 washing process

[0047]

[0048] After chemical leaching, the cadmium content in the soil can be reduced from the original 6.68mg / kg to 1.28mg / kg at most, and the cadmium removal rate can be as high as 80.81%; the lead content can be reduced from the original 787.76mg / kg to 353.70mg / kg at most. kg, the removal rate of lead was up to 55.10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com