Vertical two-side tire ring cutting machine

A ring cutting machine, double-sided technology, applied in the field of vertical double-sided tire ring cutting machine, can solve the problems of heavy workload, low production efficiency, poor safety, etc., reduce labor intensity, improve work efficiency, and prevent accidental breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

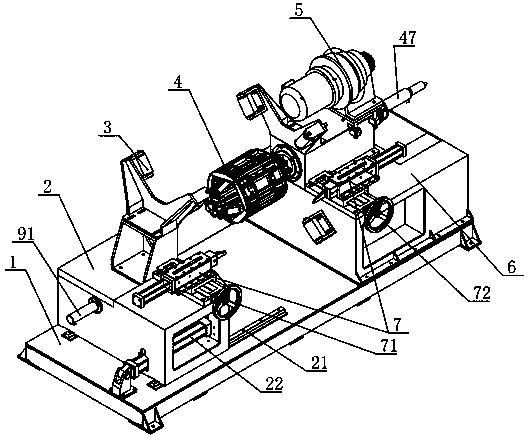

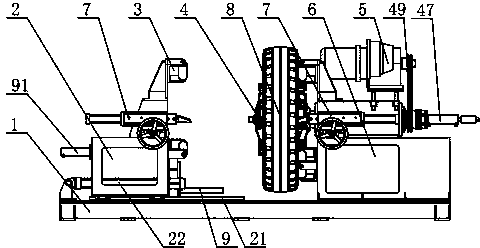

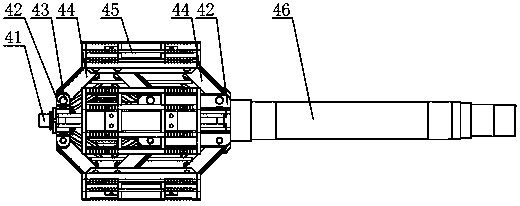

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0027] like figure 1 , figure 2 As shown, the vertical double-sided tire ring cutting machine of the present invention is provided with a fixed box 6 and a movable box 2 on the base 1, and the upper part of the fixed box 6 is provided with an expansion frame assembly 4, and the expansion frame The assembly 4 is driven by the rotary drive device 5 and rotates around the main shaft 46 as the axis; the moving box 2 is driven by the bottom cylinder 22 and moves along the transverse guide rail 21 on the base 1 to approach or move away from the fixed box 6 . On the opposite side of the fixed box 6 and the mobile box 2, several groups of clamping rollers 3 are arranged radially and divergently around the main shaft 46; On the side opposite to the front of the mobile box body 2; the mobile box body 2 is also provided with a lifting frame 9, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com