Installation structure of electric furnace induction coil for fluoride salt production

A technology of electric furnace induction coil and installation structure, which is applied in the direction of aluminum fluoride and aluminum halide, and can solve the problems of easy damage of graphite crucible and refractory materials, failure to prevent leakage of fluoride salt, explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

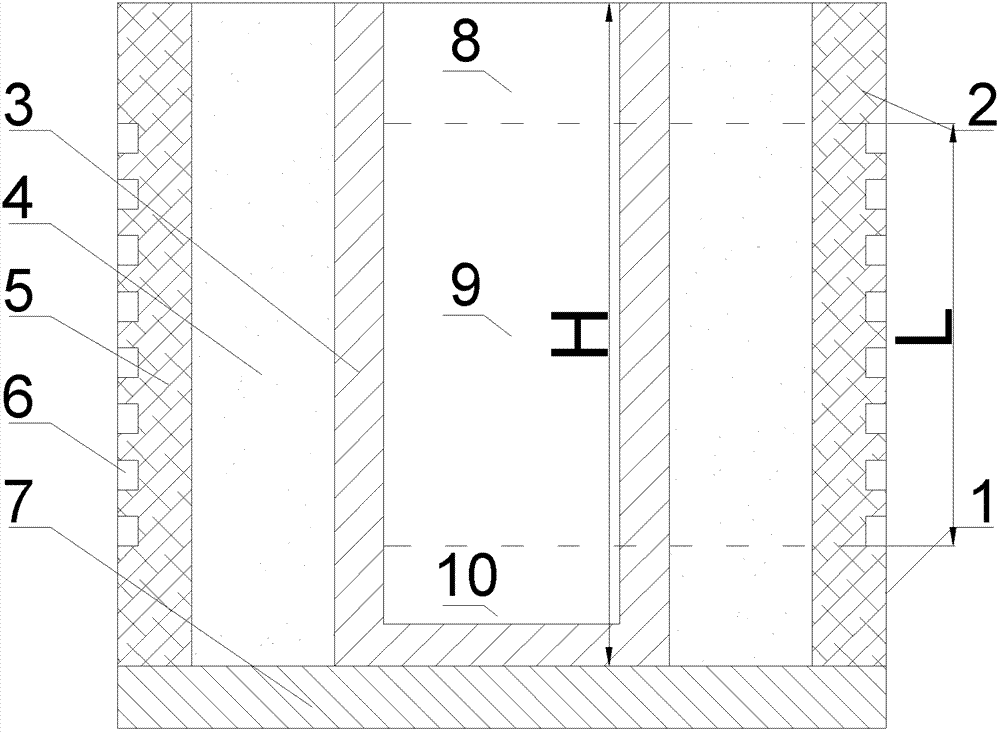

[0015] Embodiment 2 of the present invention. The installation structure of the electric furnace induction coil for fluoride salt production in the present invention is to install the induction coil layer 2 on the furnace body 1, place the graphite crucible 3 in the middle of the furnace body 1, and place the induction coil layer 2 and the graphite crucible 3 between the induction coil layer 2 and the graphite crucible Calcium oxide layer 4. Calcium oxide layer 4 selects quicklime that has just been fired, has no moisture, and has high purity. The induction coil layer 2 includes an induction coil 6 supported by refractory cement 5, and the induction coil 6 should be installed in the middle of the graphite crucible 3, and the graphite crucible 3 is divided into a feeding area 8, a reaction area 9, and a precipitation area 10; upon application According to human experiments, the installation length L of the induction coil 6 is 280-320 mm less than the height H of the graphite c...

Embodiment 3

[0018] Embodiment 3 of the present invention. The installation structure of the electric furnace induction coil for fluoride salt production, the installation structure of the electric furnace induction coil for the production of fluoride salt in the present invention, the induction coil layer 2 is installed on the furnace body 1, the graphite crucible 3 is placed in the middle of the furnace body 1, and the induction coil A calcium oxide layer 4 is placed between the layer 2 and the graphite crucible 3 . Calcium oxide layer 4 selects quicklime that has just been fired, has no moisture, and has high purity. The induction coil layer 2 includes an induction coil 6 supported by refractory cement 5, and the induction coil 6 should be installed in the middle of the graphite crucible 3, and the graphite crucible 3 is divided into a feeding area 8, a reaction area 9, and a precipitation area 10; upon application According to human experiments, the installation length L of the induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com