Durable polyvinyl chloride salt membrane composition and preparation method thereof

A technology of polyvinyl chloride and composition is applied in the field of durable polyvinyl chloride salt film composition and preparation thereof, which can solve problems such as poor durability, and achieve the effects of good durability, high cost performance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

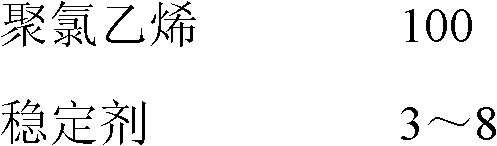

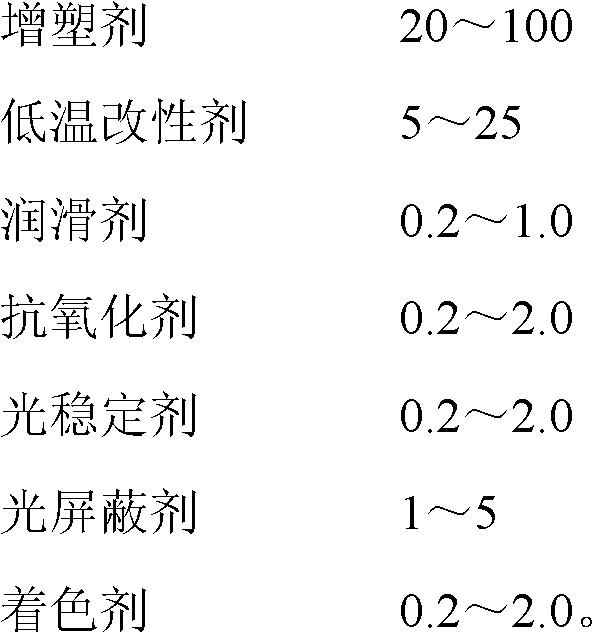

[0034] The formula of embodiment 1~5 is as shown in table 1 below:

[0035] Formulation table of table 1 embodiment 1~5

[0036]

Example 1

Example 2

Example 3

Example 4

Example 5

PVC (P=2500)

100

100

100

100

100

Calcium Zinc Composite Stabilizer

4

5

6

7

8

TOTM

10

10

10

20

20

TOPM

30

40

40

30

10

Polyester plasticizer

0

0

0

0

10

EVA

20

10

5

5

5

CPE

5

5

0

5

5

Antioxidant 1010

1.0

1.5

1.5

1.0

0.5

0.6

0.4

0.4

0.6

0.2

PE wax

0.4

0.2

0.4

0.2

0.2

Titanium dioxide

4

4

4

4

4

Light stabilizer UV-419

1.0

1.0

1.0

1.5

1...

Embodiment 1~10

[0043] The preparation method of embodiment 1~10:

[0044] (1) Mixing of raw materials: Weigh the materials according to the ratio of raw materials, then add them to the high-speed mixer and mix until the mixing temperature is 120°C, put the materials into the low-speed mixer, and discharge the materials when the temperature of the materials cools down to 40°C.

[0045] (2) Granulation process: The mixed material is granulated by twin-screw, and the process parameters are set as follows:

[0046] Extruder temperature (°C): Zone 1, Zone 2, Zone 3, Zone 4, Zone 5

[0047] 110 120 130 140 150 150

[0048] (3) Calendering process: the pellets are calendered into a film with a calender, and the process parameters are set as follows:

[0049] Calender roll temperature (°C): 1 roll, 2 rolls, 3 rolls, 4 rolls, 5 rolls

[0050] 190 185 175 170 150

Embodiment 11~15

[0051] The preparation method of embodiment 11~15:

[0052] (1) Mixing of raw materials: Weigh the materials according to the ratio of raw materials, then add them to the high-speed mixer and mix until the mixing temperature is 120°C, put the materials into the low-speed mixer, and discharge the materials when the temperature of the materials cools down to 40°C.

[0053] (2) Calendering process: the pellets are calendered into a film with a calender, and the process parameters are set as follows:

[0054] Calender roll temperature (°C): 1 roll, 2 rolls, 3 rolls, 4 rolls, 5 rolls

[0055] 200 195 185 180 160

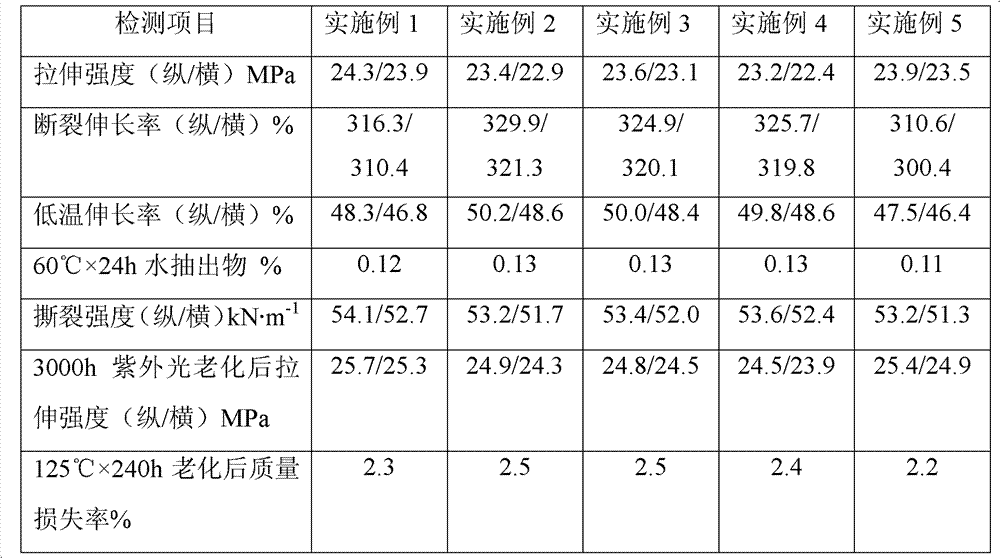

[0056] Performance test method: After mixing the materials, use a double-roll mill to open the sheet, press the sample sheet at 180°C in a molding machine, and test the performance after preparing the test sample. The result is as follows:

[0057] The performance test result of embodiment 1~5 is as shown in table 4 below:

[0058] Table 4 Embodiment 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com