Preparation method of unsaturated polyester wear-resistant paint

A wear-resistant coating, unsaturated technology, applied in the field of coatings, to achieve the effect of improving wear resistance, good physical properties, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

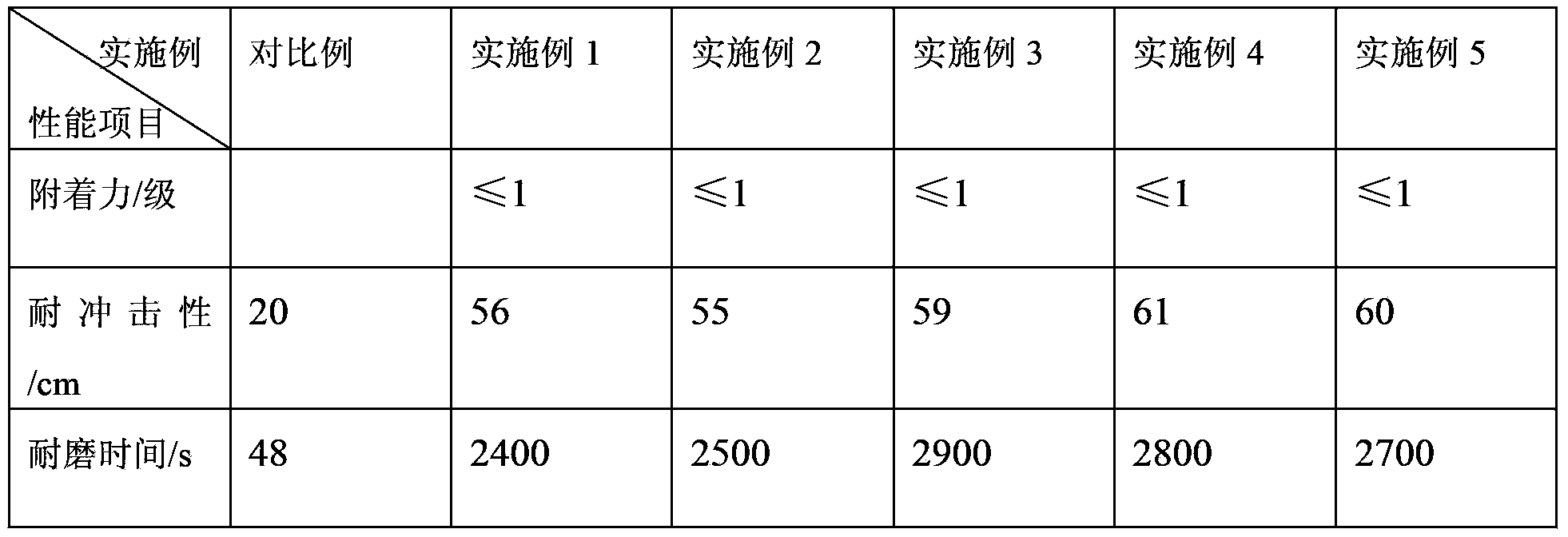

Examples

Embodiment 1

[0015] An unsaturated polyester wear-resistant coating, its components are composed of the following components by weight percentage: 40% of the A component and 60% of the B component; the A component includes the following components by weight: 98 Parts of unsaturated polyester resin, 2 parts of mass concentration are 60% cyclohexanone peroxide solution, 3 parts of methyl ethyl ketone peroxide; the B component includes the following components in parts by weight: 98 parts of unsaturated polyester resin, 5 parts Part mass concentration is 90% cobalt naphthenate, 1 part ammonium polyphosphate.

[0016] The preparation method of the above-mentioned wear-resistant coating for colored steel plates comprises the following steps:

[0017] (1) Preparation of component A: weigh each raw material in component A according to the raw material components, put the unsaturated polyester resin into the reaction kettle, then add cyclohexanone peroxide solution and methyl ethyl ketone peroxide...

Embodiment 2

[0021] A kind of unsaturated polyester wear-resistant coating, its component is made up of following composition by weight percentage: 60% of A component and 40% of B component; Described A component comprises following component by weight: 80% Parts of unsaturated polyester resin, 5 parts of mass concentration are 60% cyclohexanone peroxide solution, 1 part of methyl ethyl ketone peroxide; the B component includes the following components in parts by weight: 80 parts of unsaturated polyester resin, 2 parts Parts mass concentration is 90% cobalt naphthenate, 3 parts ammonium polyphosphate.

[0022] The preparation method of the above-mentioned wear-resistant coating for colored steel plates comprises the following steps:

[0023] (1) Preparation of component A: weigh each raw material in component A according to the raw material components, put the unsaturated polyester resin into the reaction kettle, then add cyclohexanone peroxide solution and methyl ethyl ketone peroxide, s...

Embodiment 3

[0027] A kind of unsaturated polyester wear-resistant coating, its component is made up of following composition by weight percentage: A component of 50% and B component of 50%; Described A component comprises following component by weight: 90% Parts of unsaturated polyester resin, 4 parts of mass concentration are 60% cyclohexanone peroxide solution, 2 parts of methyl ethyl ketone peroxide; the B component includes the following components in parts by weight: 90 parts of unsaturated polyester resin, 4 parts Part mass concentration is 90% cobalt naphthenate, 2 parts ammonium polyphosphate.

[0028] The preparation method of the above-mentioned wear-resistant coating for colored steel plates comprises the following steps:

[0029] (1) Preparation of component A: weigh each raw material in component A according to the raw material components, put the unsaturated polyester resin into the reaction kettle, then add cyclohexanone peroxide solution and methyl ethyl ketone peroxide, s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap