Aroma compound

A compound and aroma-inducing technology, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problem that it is difficult to achieve the characteristic flavor of natural plants, and achieve the effect of low price, sufficient source, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

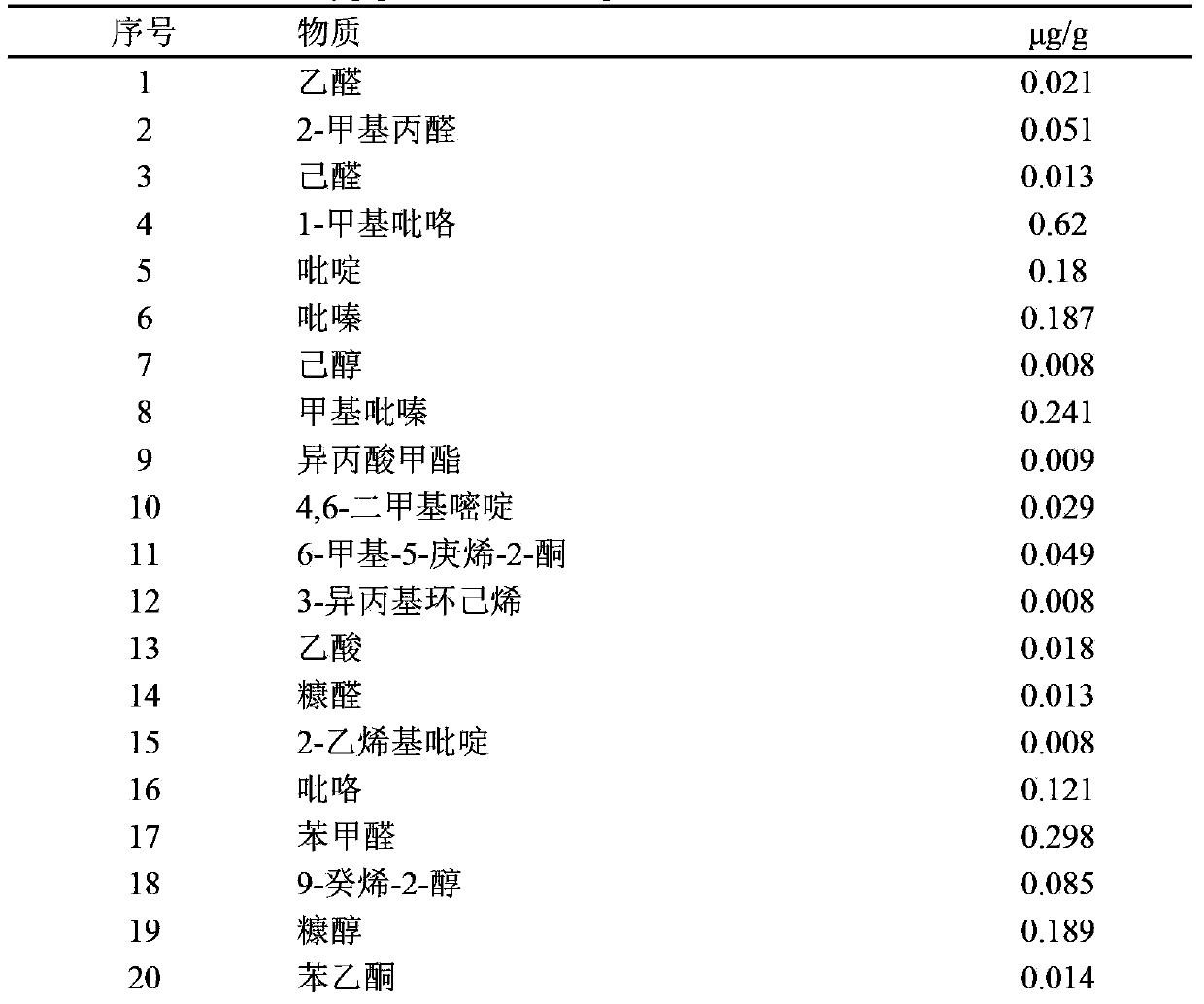

[0039] Embodiment 2 low grade tobacco leaves

[0040] (1) Take 4kg of low-grade tobacco leaves, dry them in an oven at 60°C for 12 hours, crush them and filter them through a 60-mesh sieve, add 16L of pure water to make the ratio of material to liquid 1:4, put them in an ultrasonic crushing tank, 3W / cm 2 , broken for 1.5h;

[0041] (2) Take 20g of citric acid, add 100mL of water, dissolve and set the volume to 200mL to obtain citric acid solution; take 100mL of citric acid solution, add 400mL of water and stir evenly, add it to the reaction tank, measure the pH value after stirring for 2 minutes, and adjust the pH value It was 4.5, and the initial extract was obtained;

[0042] (3) Mix 200mL of the initial extract with 2L of pure water, add 6mL of compound plant hydrolase after mixing, add to the reaction tank and react for 4h, the reaction temperature is 48°C, and the pH value is 7.2;

[0043] (4) After raising the temperature of the reaction tank to 80°C, keep it for 10 m...

Embodiment 3

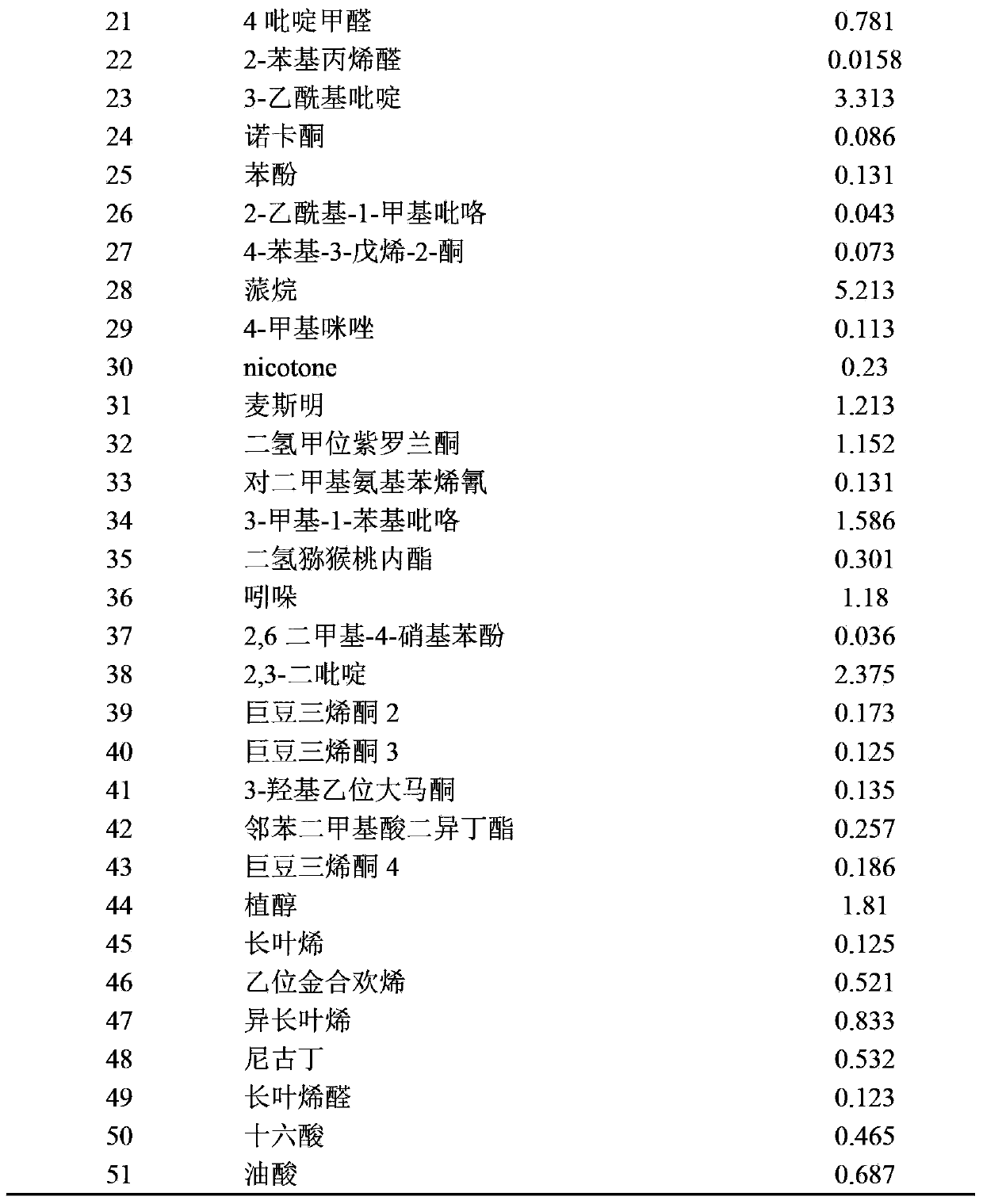

[0051] Example 3 Agarwood

[0052] (1) Take 4kg of agarwood, dry it in an oven at 60°C for 4 hours, crush it and filter it through a 60-mesh sieve, add 16L of pure water to make the ratio of material to liquid 1:4, put it in an ultrasonic crushing tank, and use it at an ultrasonic intensity of 3W / cm 2 , broken for 1.5h;

[0053] (2) Take 20g of citric acid, add 100mL of water, dissolve and set the volume to 200mL to obtain citric acid solution; take 100mL of citric acid solution, add 400mL of water and stir evenly, add it to the reaction tank, measure the pH value after stirring for 2 minutes, and adjust the pH value It was 4.5, and the initial extract was obtained;

[0054] (3) Mix 200mL of the initial extract with 2L of purified water, add 6mL of compound plant hydrolase after mixing, add to the reaction tank and react for 4h, the reaction temperature is 50°C, and the pH value is 6.5;

[0055] (4) After raising the temperature of the reaction tank to 80°C, keep it for 10...

Embodiment 5

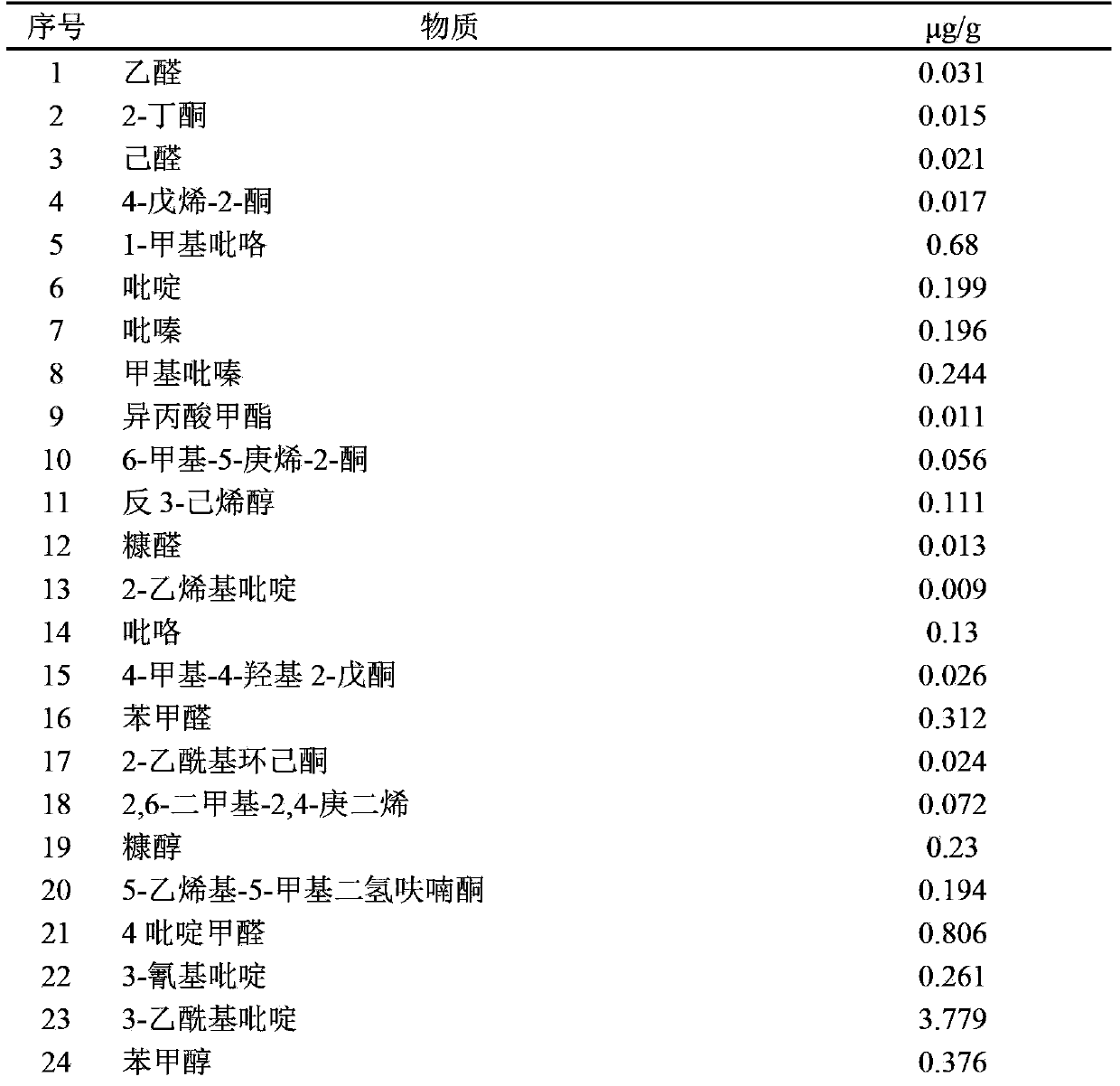

[0075] Example 5 Sage

[0076] (1) Take 4kg of sage, dry it in an oven at 60°C for 18 hours, crush it and filter it through a 60-mesh sieve, add 16L of pure water to make the ratio of material to liquid 1:4, put it in an ultrasonic crushing tank, 3W / cm 2 , broken for 1.5h;

[0077] (2) Take 20g of citric acid, add 100mL of water, dissolve and set the volume to 200mL to obtain citric acid solution; take 100mL of citric acid solution, add 400mL of water and stir evenly, add it to the reaction tank, measure the pH value after stirring for 2 minutes, and adjust the pH value It was 4.5, and the initial extract was obtained;

[0078] (3) Mix 200mL of the initial extract with 2L of purified water, add 6mL of compound plant hydrolase after mixing, add to the reaction tank and react for 4h, the reaction temperature is 45°C, and the pH value is 6.2;

[0079] (4) After raising the temperature of the reaction tank to 80°C, keep it for 10 minutes, and then turn on the condensate water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com