Aluminum alloy forged material for automotive vehicles and production method for the material

一种制造方法、铝合金的技术,应用在汽车用铝合金锻造材及其制造领域,能够解决耐腐蚀性低等问题,达到抗拉强度优异、屈服强度和延伸率优异、维持耐腐蚀性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11、 comparative example 1~21

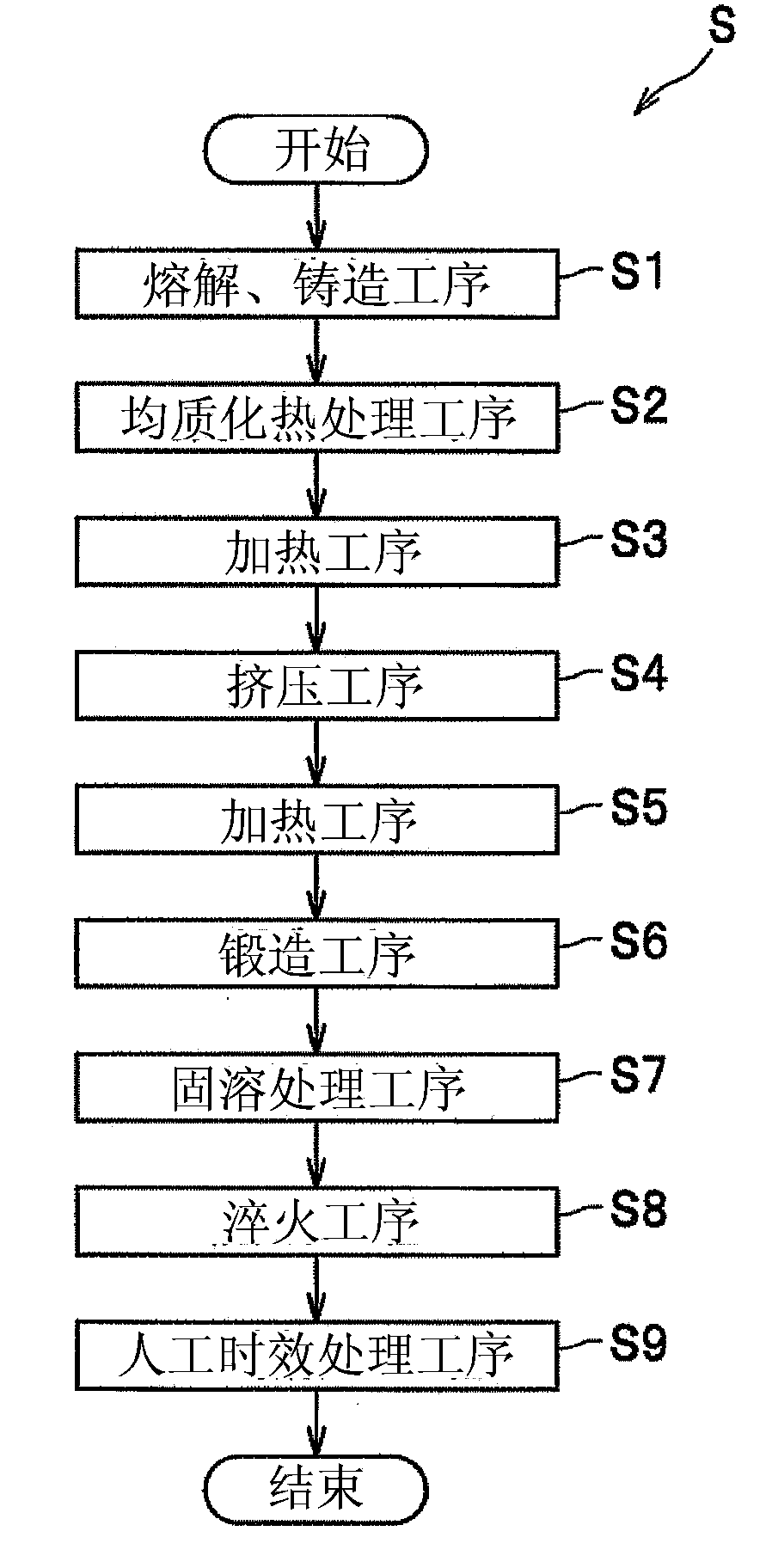

[0132] Before the casting process, Al alloys having various alloy compositions shown in Table 1 were used for casting by hot top casting at a heating temperature of 720° C. and a casting speed of 30 mm / min. The obtained ingot had a diameter of φ300 mm. Thereafter, the ingot was heated at a heating rate of 1.5° C. / min, held at 540° C.×8 hours, cooled to 300° C. or lower at 3° C. / min., and subjected to homogenization heat treatment.

[0133] Then, it heated to 520 degreeC using the air furnace, and held it for 1.5 hours, and heat-processed. Next, the heat-treated ingot was not cooled, but was directly extruded using an extruder under the following conditions.

[0134] Extrusion temperature: 500°C, extrusion ratio: 21.3, extrusion speed: 3m / min

[0135] The extrusion-processed molded article was heated to 520° C. using an air furnace and held for 1.5 hours to perform heat treatment. The heat-treated molded product is not cooled, but the following forging process is performed. ...

Embodiment 12~17、 comparative example 22~53

[0146] Before the casting process, the aluminum alloy with the composition described in Example 3 of Table 1, that is, Si: 1.20 mass%, Fe: 0.45 mass%, Cu: 0.07 mass%, Mg: 1.00 mass%, Ti: 0.02 mass% was used , Zn: less than 0.02% by mass, Mn: 0.65% by mass, Cr: 0.20% by mass, Zr: less than 0.01% by mass, the amount of hydrogen is 0.15ml / 100gAl, and the balance is composed of Al and unavoidable impurities. Using the production conditions described in Table 3, aluminum alloy forged materials were produced in the same manner as in Examples 1 to 11. The production conditions other than those described in Table 3 were the same as in Examples 1-11.

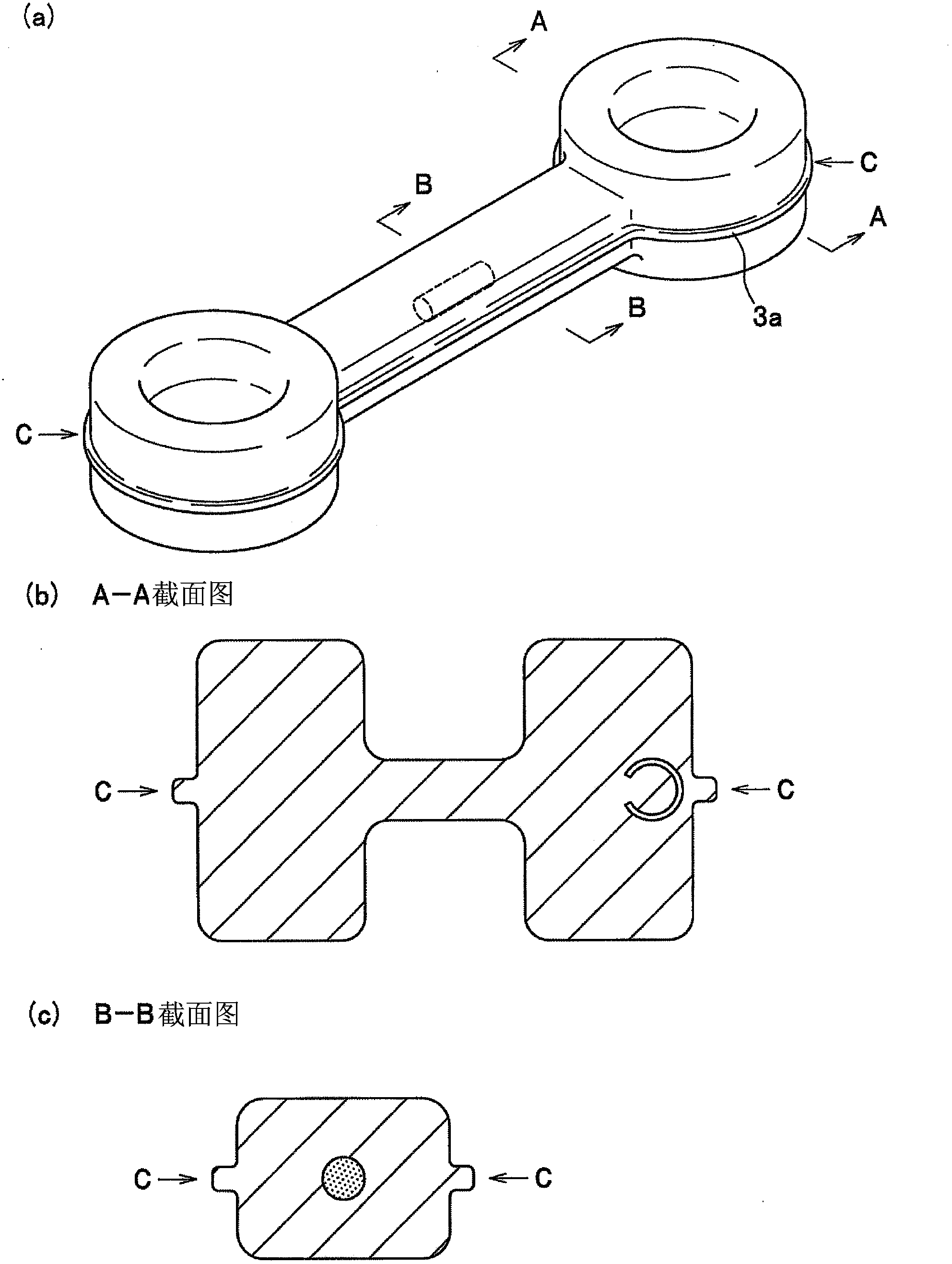

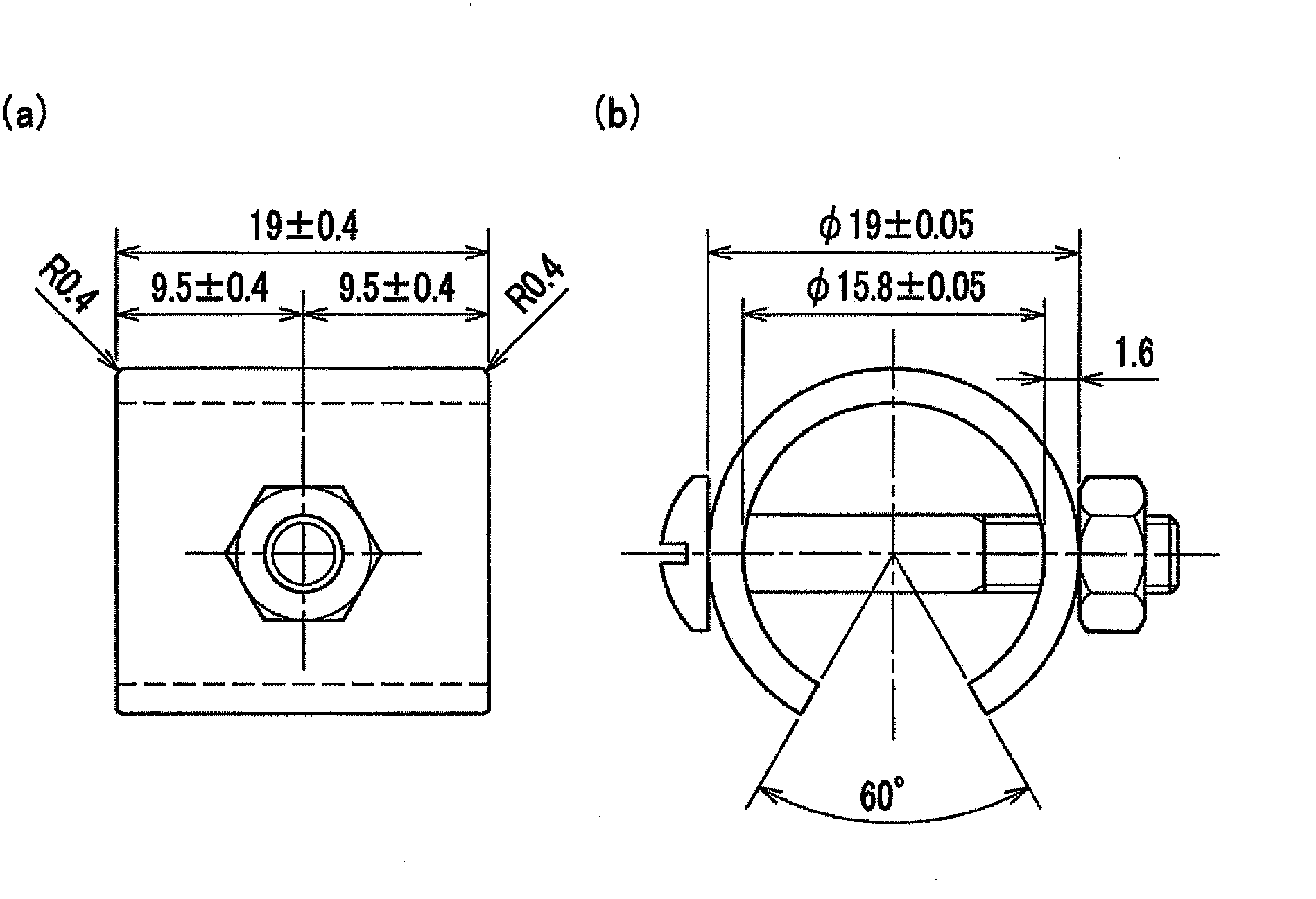

[0147] From the Al alloy forged material thus obtained, in the same manner as in Examples 1 to 11, the figure 2 In the positions shown, the test piece for the tensile test and the test piece for stress corrosion cracking resistance (SCC) evaluation (C ring) were extracted.

[0148] The obtained forged materials were evaluated for tens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com